Water-cooled reactor for methanol synthesis

A water-cooled reactor, methanol synthesis technology, applied in chemical instruments and methods, hydroxyl compound preparation, organic compound preparation, etc. Vapor pressure rise and other problems, to avoid the increase of the wall thickness of the heat exchange tube, to avoid difficult control, and to reduce equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

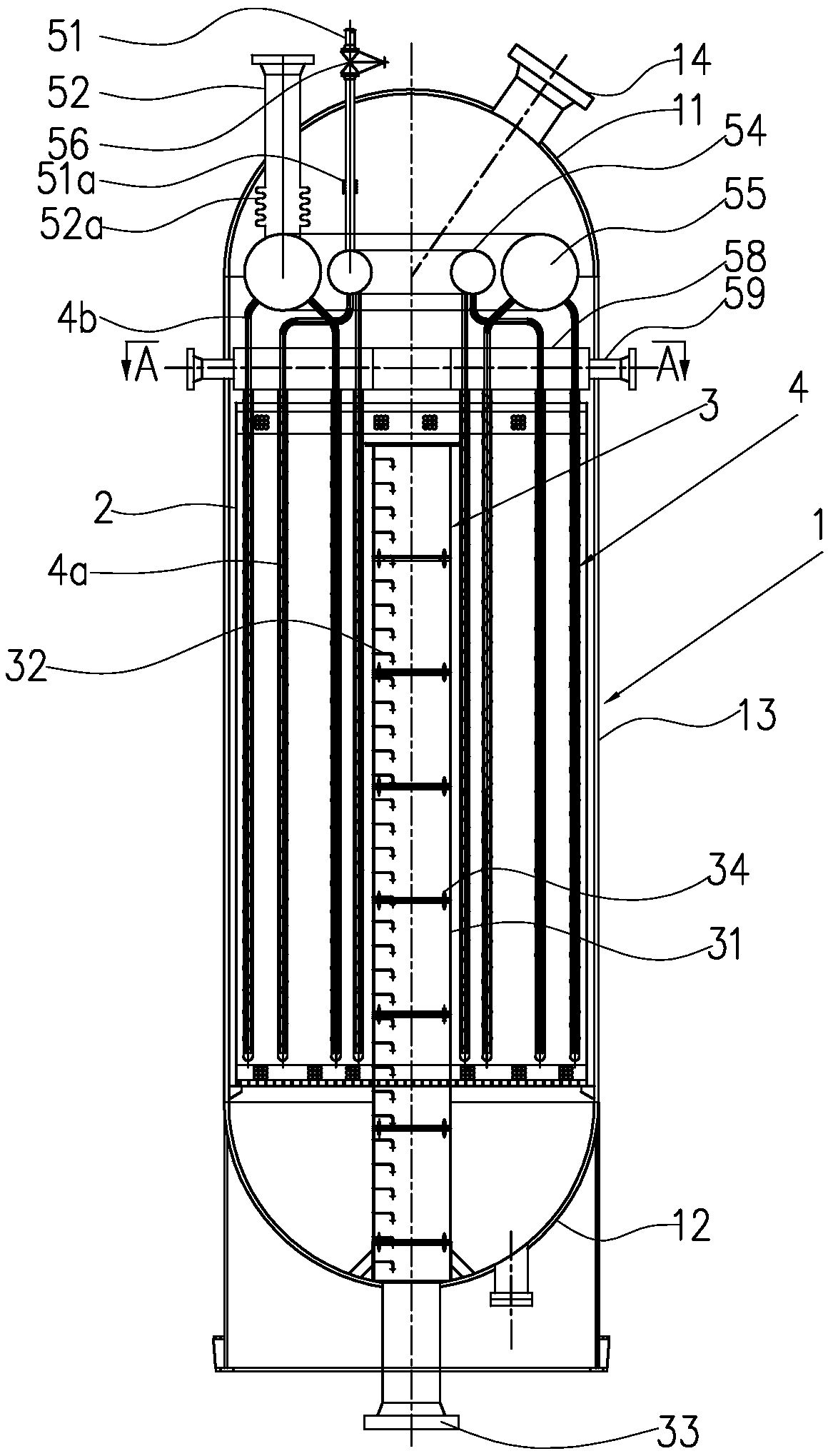

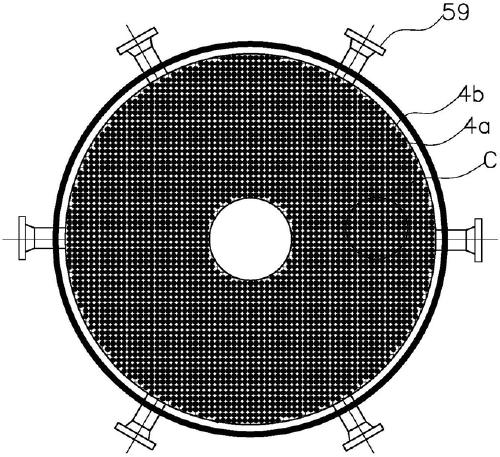

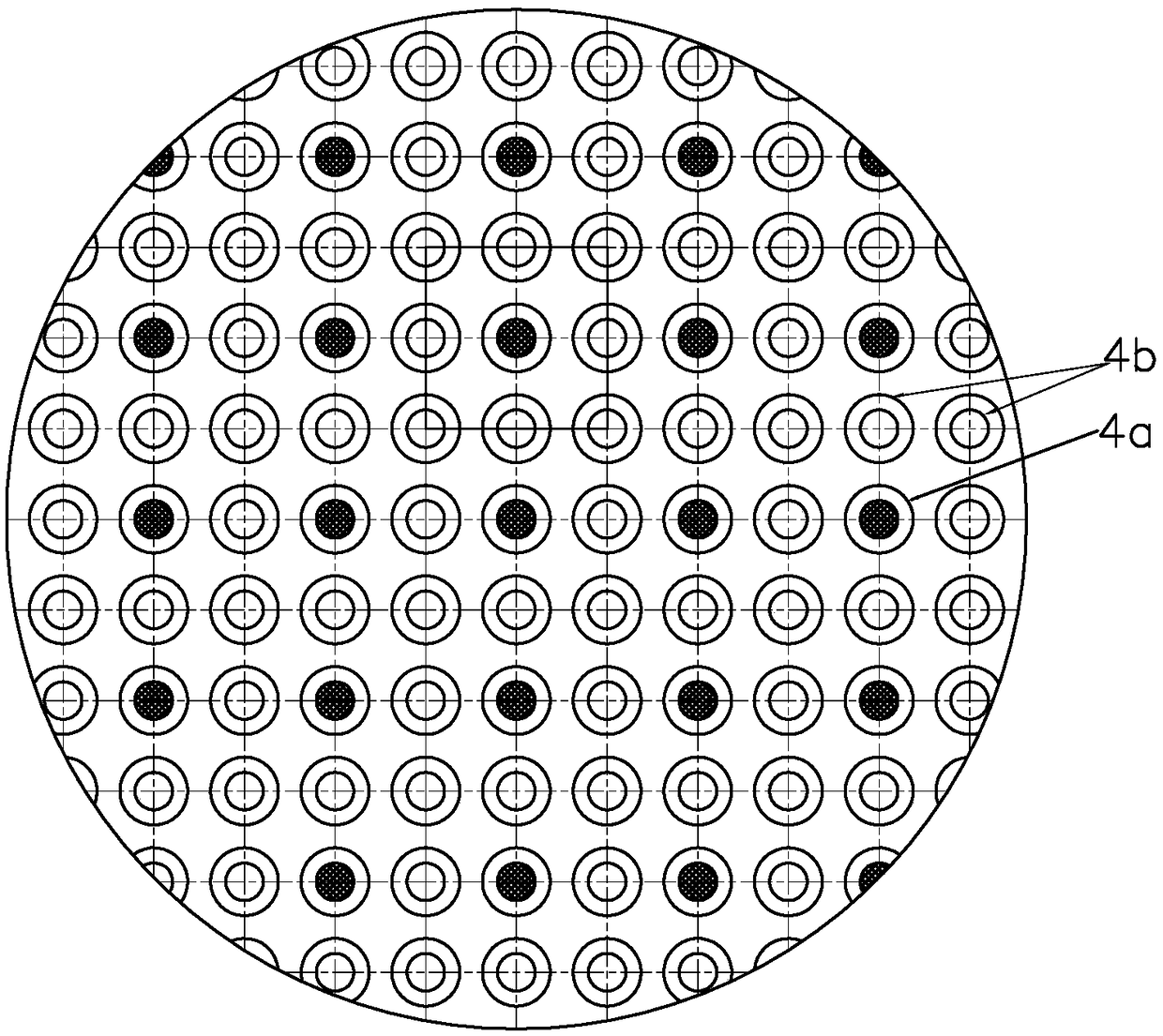

[0040] Such as Figure 1 to Figure 6 As shown, the water-cooled reactor for methanol synthesis includes:

[0041]The body of furnace 1 is a conventional structure, comprising an upper head 11, a lower head 12 and a cylinder 13 connected between the upper head 11 and the lower head 12; the top of the body of furnace 1 is provided with a feed gas inlet 14, and the furnace The bottom of the body 1 is provided with a synthesis gas outlet.

[0042] The catalyst frame 2 is arranged in the cylinder body 13 . Catalyst frame 2 can be selected from any one of the prior art according to needs. This embodiment is a radial reactor. There is a gap between the side wall of the catalyst frame and the side wall of the furnace body. The gap forms a feed gas channel. A plurality of feed gas inlet holes (not shown in the figure) are provided on the side wall; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com