Calcination device for chemical production

A chemical production and calcination device technology, applied in calcination, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to automatically process chemical raw materials, inconvenient operation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

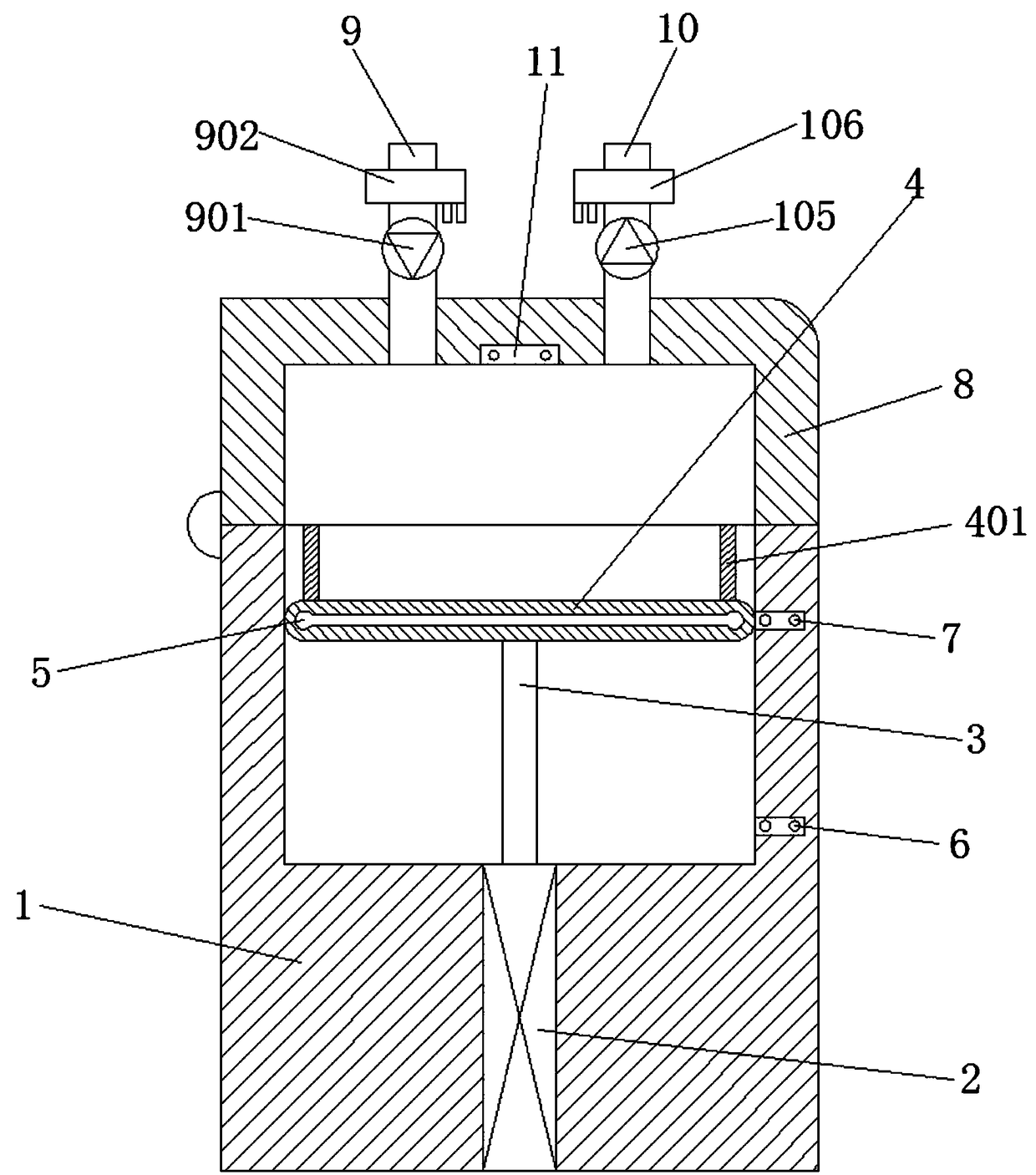

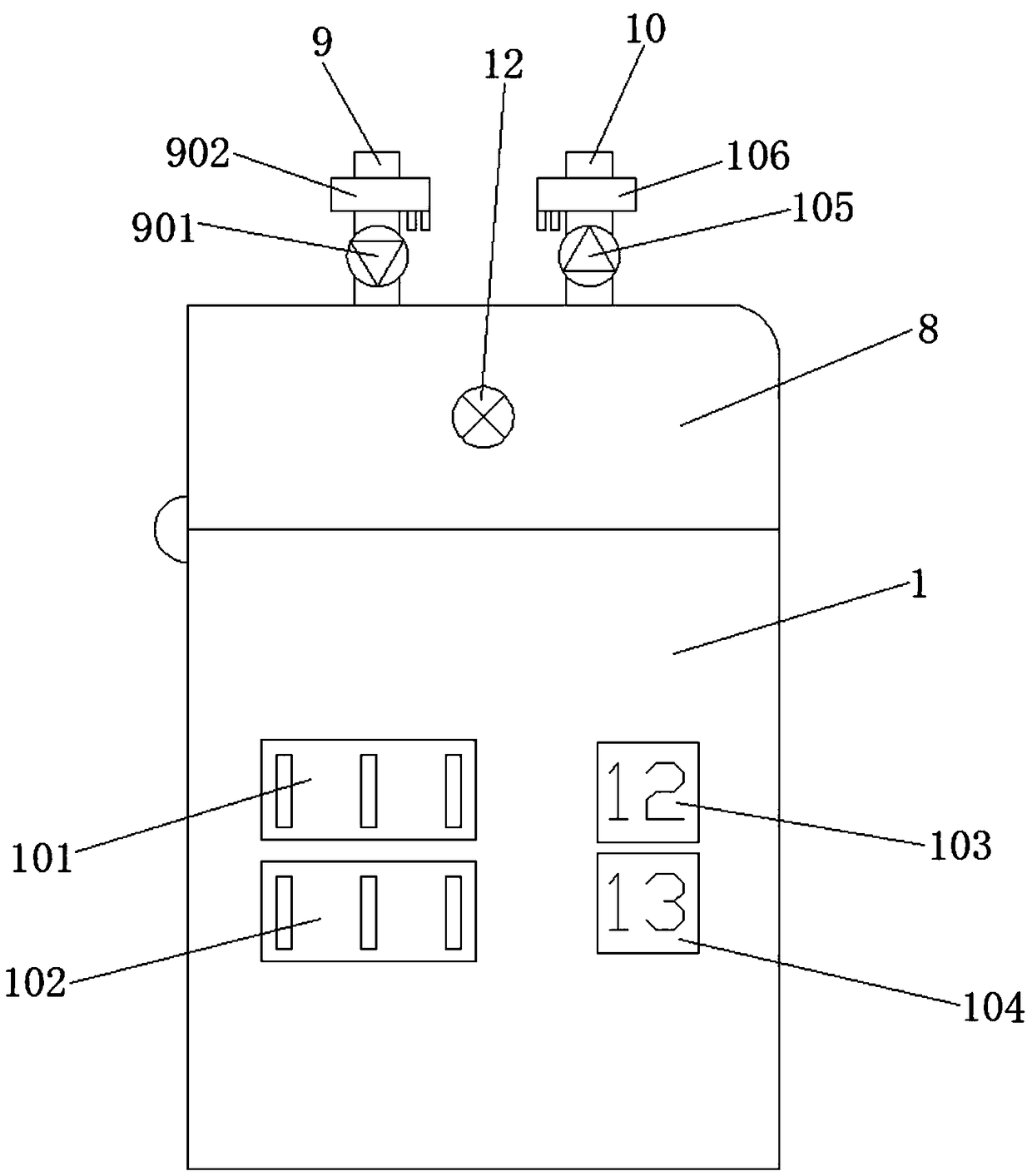

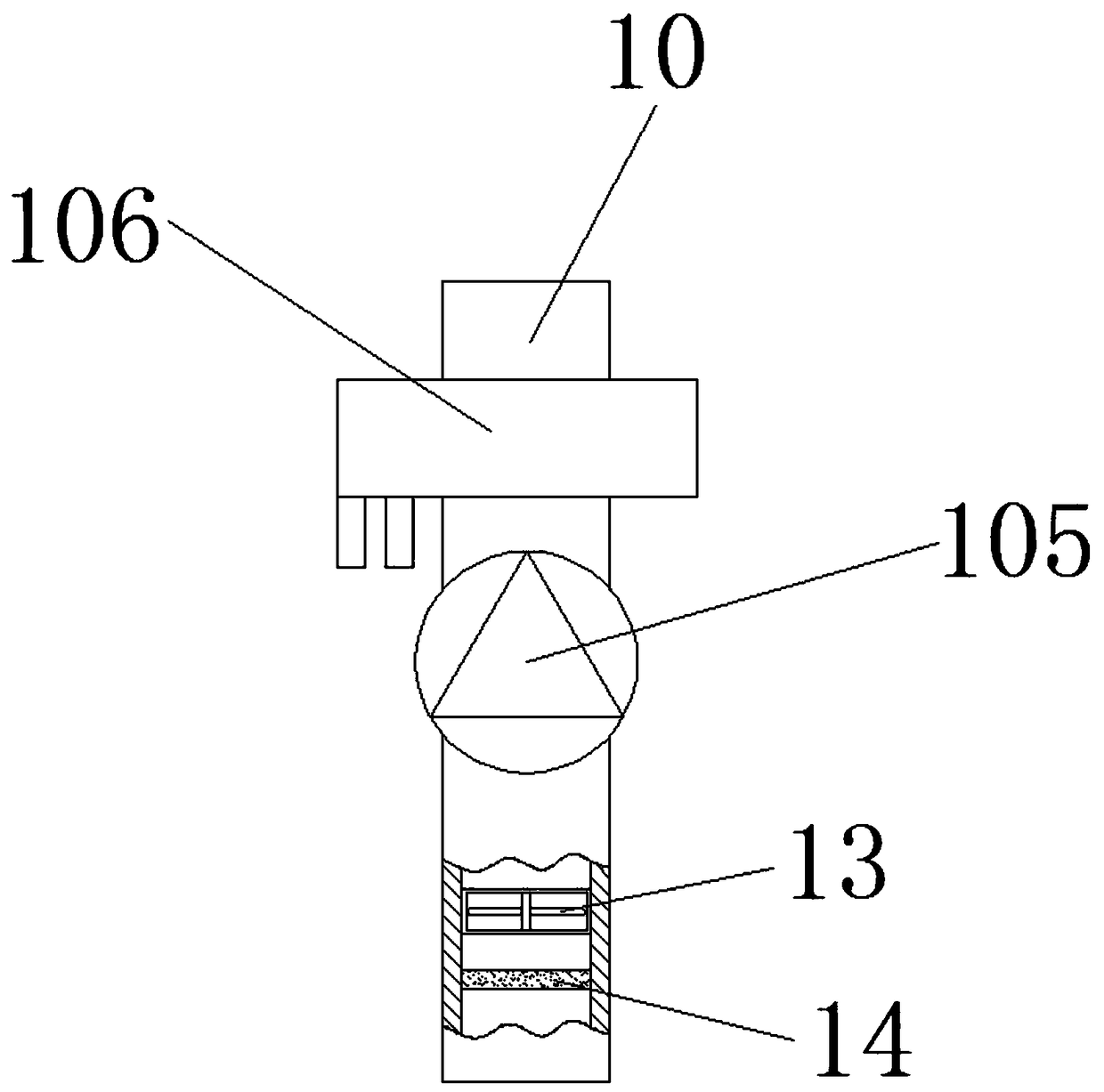

[0021] Such as figure 1 , figure 2 , image 3As shown, the calcining device for chemical production includes a frame 1, an electric push rod 2, a connecting rod 3, a support plate 4, a heating pipe 5, a first metal sensor 6, a second metal sensor 7, a sealing cover 8, an air intake pipe 9, Exhaust pipe 10, temperature sensor 11, warning light 12, exhaust fan 13, filter screen 14, described electric push rod 2 is located at the middle side of the lower end inside frame 1, and described electric push rod 2 is connected with frame 1 screw thread, and described The connecting rod 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com