Sliding contact moving conduction device

A conductive device, sliding contact technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of unstable power transmission, running track deviation, separation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

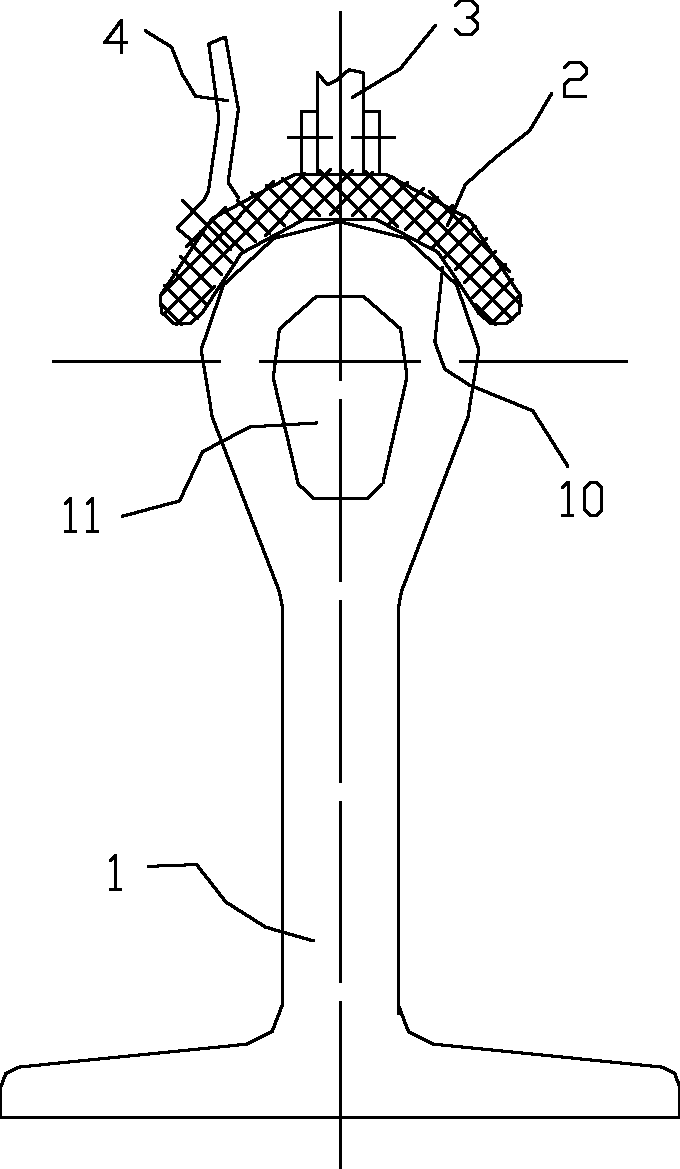

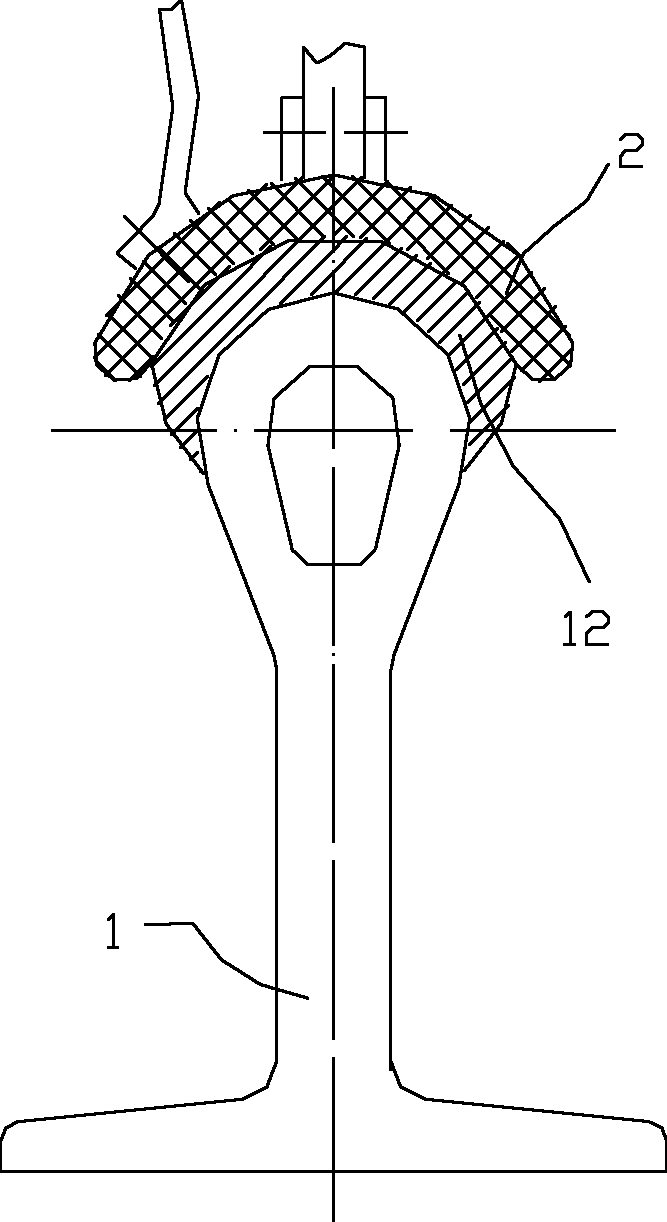

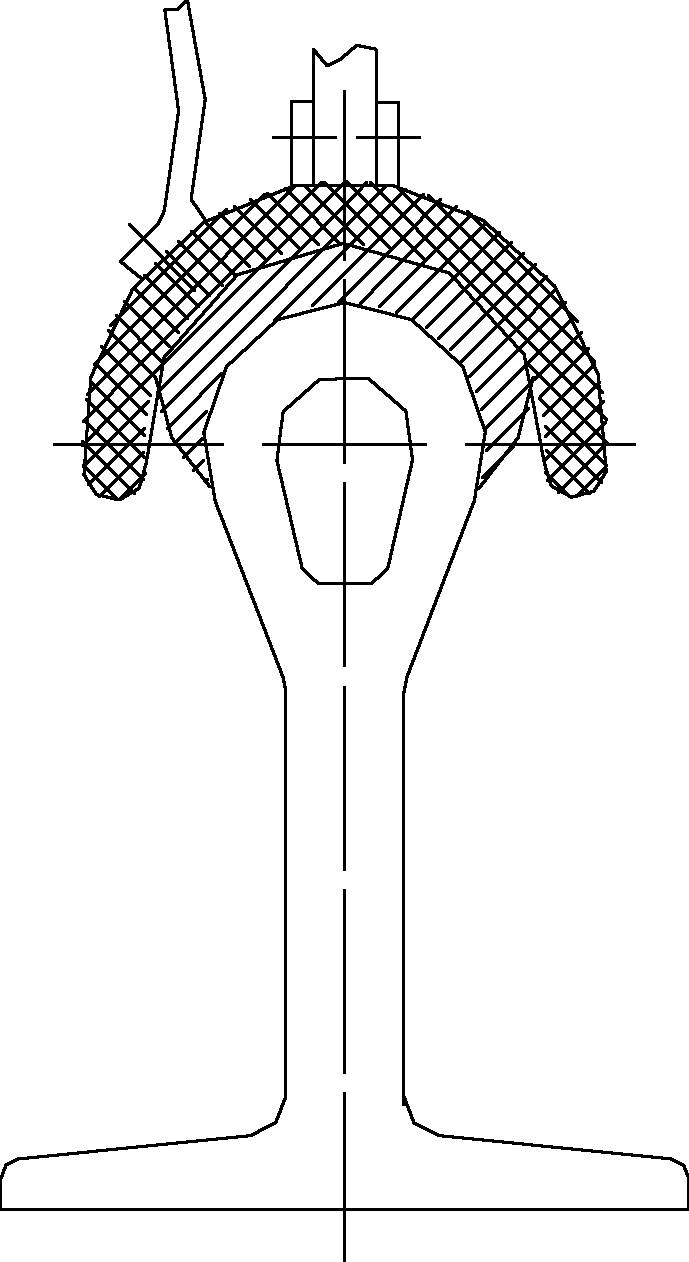

[0019] Such as Figure 1-4 As shown, the present invention includes a trolley line 1, a guide rail and a running part provided with a collector, the trolley line 1 has a conductive working surface 10, and the trolley line 1 is parallel to the guide rail; the running part is along the The guide rail runs; the collector includes a collector arm 3, a brush 2, a conductive strip 4 and a bottom plate, and the bottom plate is fixedly connected to the moving part; the working surface of the brush 2 contacts the sliding contact line working face 10;

[0020] From the cross section, the working surface of the trolley line 1 is convex arc-shaped;

[0021] From the cross section, the working surface of the brush 2 is in a concave arc shape consistent with the working surface 10 of the trolley line.

[0022] The convex arc shape of the trolley line working surface 10 is a circular arc shape.

[0023] The convex arc of the working surface of the trolley line is a superior arc larger tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com