Barrel member group and lens capable of intensifying impact bearing

A barrel and lens technology, which is applied in the field of barrel sets and lenses, can solve problems such as reduced output, inability to make thinner products, and uncompetitive products, and achieve the effect of avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

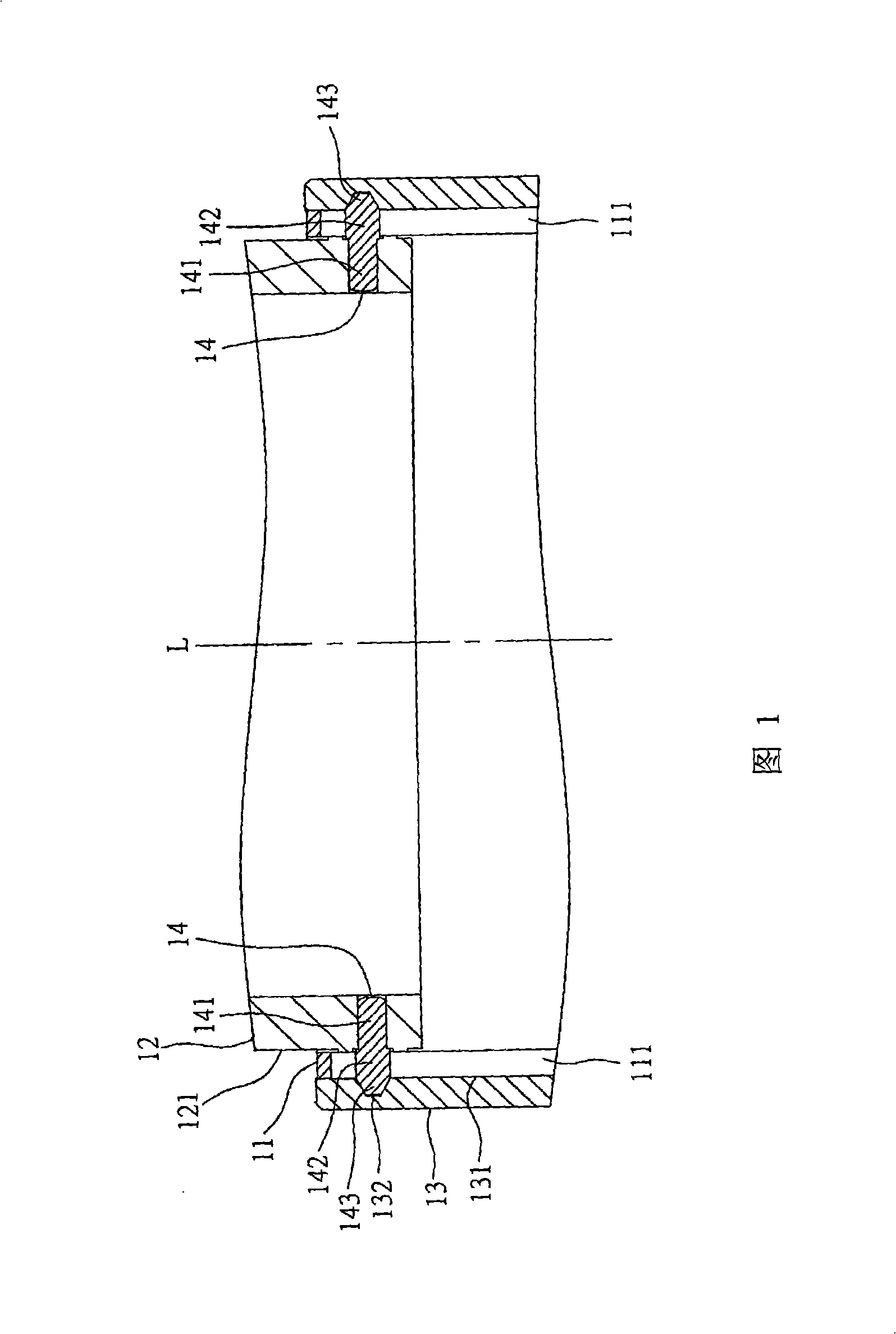

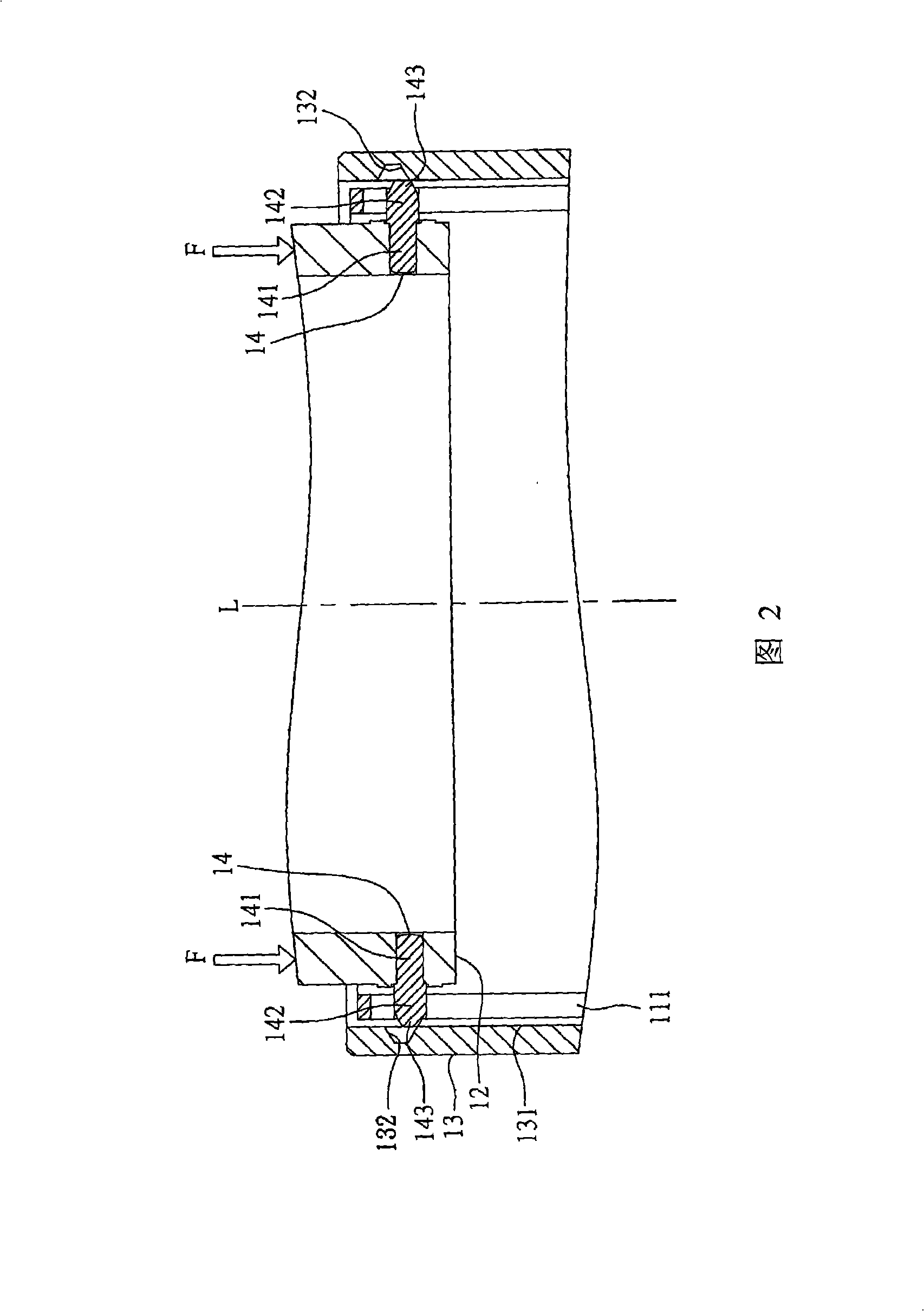

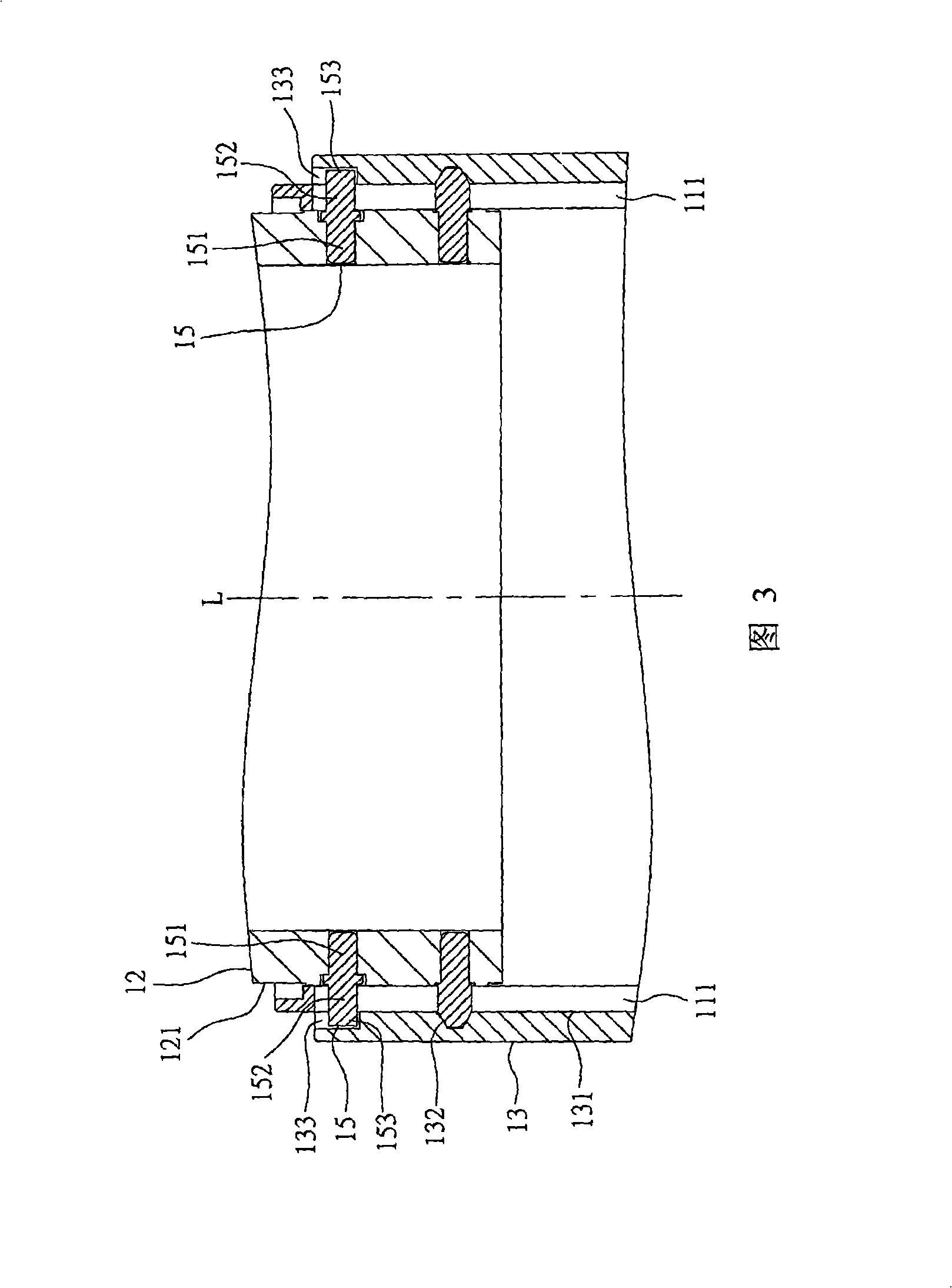

[0034] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with accompanying drawings.

[0035] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same reference numerals.

[0036] Such as Figure 5 , 6, and 7 are respectively an exploded perspective view of the barrel assembly of the present invention, a side sectional view of the lens of the present invention, and a sectional view of A-A in FIG. 6 . The first preferred embodiment of the impact-resistant barrel assembly of the present invention includes a fixed barrel 20 , a first barrel 30 , a second barrel 40 , three interlocking guide pins 50 , and an outer barrel 60 .

[0037] In a further specific application of the present invention, the fixed cylinder 20 is regarded as a straight-in cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com