Preparation method of composite membrane for efficiently filtering micro-pollutants in water

A high-efficiency filtration and composite membrane technology, applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of reducing adsorption effect and easy loss, and achieve simple preparation process, low cost and high application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a composite membrane for efficiently filtering micro-pollutants in water, comprising the steps of:

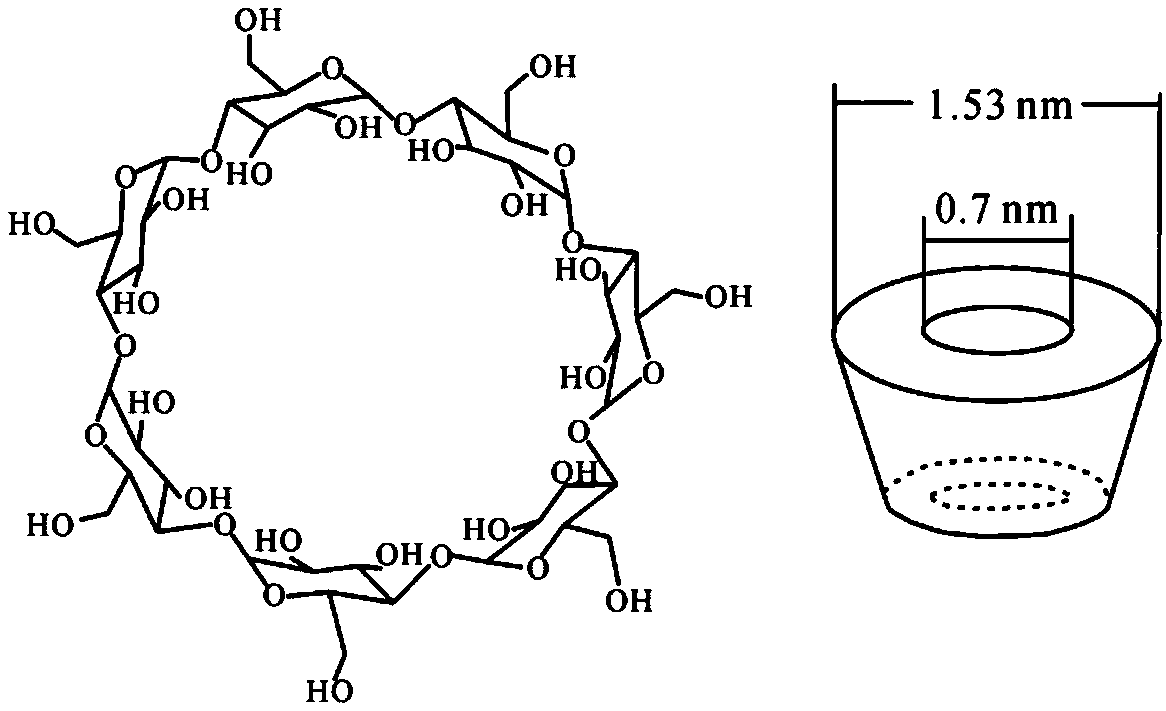

[0021] (1) Mix the film-forming polymer, functionalized β-cyclodextrin, porogen, cross-linking agent and solvent according to a certain mass ratio, dissolve it by mechanical stirring at 40-100°C, react for 5-10 hours and vacuumize After defoaming, the casting solution is obtained. The mass ratio of each component is as follows: 10-30% for film-forming polymer; 1-10% for functionalized β-cyclodextrin; 10-20% for porogen; 0.5-5% for cross-linking agent; 35-78.5%;

[0022] (2) The film casting solution is coated by a film scraping machine or extruded from a hollow fiber spinneret, immersed in a coagulation bath to solidify and form, and form a polymer primary film;

[0023] (3) The polymer primary membrane is thoroughly washed in deionized water to obtain a composite membrane, which is used for adsorption and removal of micro-pollutants in water.

...

Embodiment 1

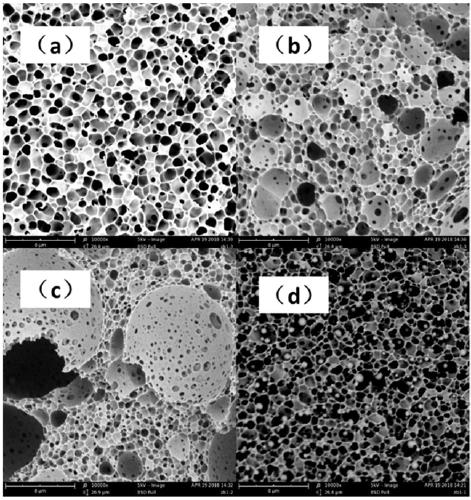

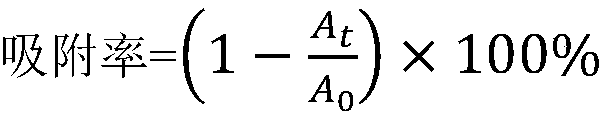

[0036] Mix the polyvinylidene fluoride, amino β-cyclodextrin, polyethylene glycol, polyethyleneimine and N,N-dimethylacetamide according to the concentration requirements of the corresponding numbers in Table 1.1, stir mechanically for 5 hours, and fully After dissolving, defoam and filter to obtain the casting solution, and let it stand for 30 minutes. The film casting liquid is coated by a film scraping machine, immersed in a coagulation bath mixed with pure water and N,N-dimethylacetamide to solidify and form, and washed with water at 25°C to obtain a sheet-shaped composite film, which is further fully cleaned with deionized water. Then stand and dry in the air to obtain a composite membrane with a pore diameter of 10 nm. Test its water flux, BSA rejection rate. The adsorption properties of organic micro-pollutants bisphenol A (BPA) and dinaphthol (2-NO) were tested.

[0037] Table 1.1: Preparation conditions of polyvinylidene fluoride / amino β-cyclodextrin composite membr...

Embodiment 2

[0043] Mix polyvinyl chloride, carboxyl β-cyclodextrin, polyvinylpyrrolidone, glutaraldehyde and N,N-dimethylformamide according to the concentration requirements of the corresponding numbers in Table 2.1, and stir mechanically for 6 hours. After fully dissolving, After defoaming and filtering, the casting solution was obtained and left to stand for 30 minutes. Extrude the casting liquid through the hollow fiber spinneret, immerse it into a coagulation bath mixed with pure water and N,N-dimethylformamide to solidify and form it, wash it with water at 25°C to obtain a hollow fiber composite membrane, and further use deionized Wash thoroughly with water, and then let it dry in the air to obtain a composite membrane with a pore size of 1 μm. Test its water flux, E. coli retention rate. The adsorption properties of organic micropollutant dichlorophenol (2,4-DCP) and plasticizer 4,4'-dihydroxydiphenylsulfone (BPS) were tested.

[0044] Table 2.1: Preparation conditions of polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com