Dust removal device used for factory processing workshop based on electrostatic dust removal technology

A technology for electrostatic dust removal and processing workshops, which is applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of insignificant processing dust treatment effect of floating dust, etc., and achieve the effect of preventing floating dust from accumulating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

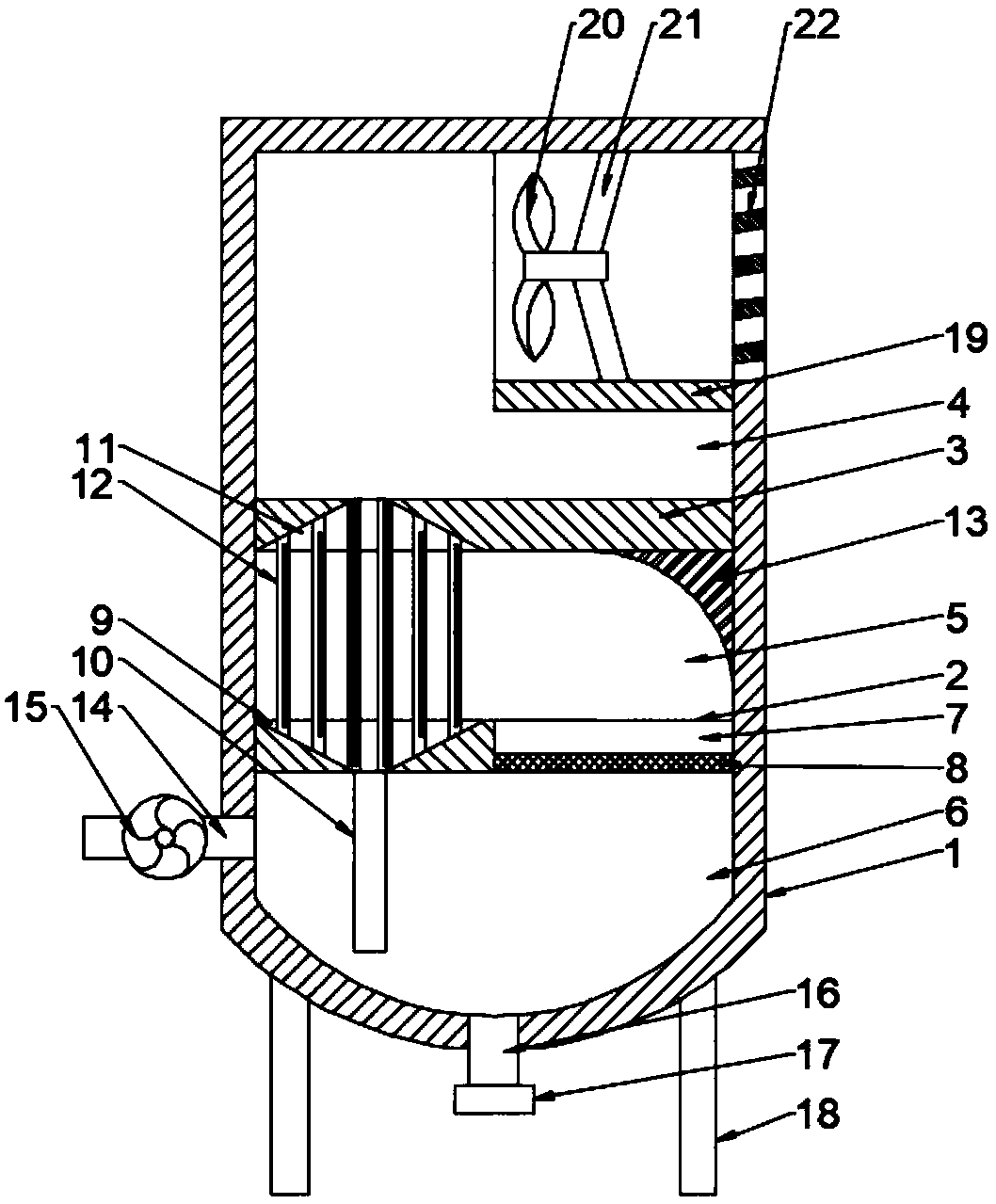

[0027] see Figure 1~3 , a dust removal device for factory processing workshops based on electrostatic dust removal technology, comprising a body 1, an upper partition 3 and a lower partition 2 are provided at the bottom of the inner cavity of the body 1, and the upper partition 3 is arranged on the lower partition 2 Above, the upper partition 3 and the lower partition 2 divide the inner chamber of the body 1 into an exhaust chamber 4, a dust removal chamber 5 and an air intake chamber 6 in sequence from top to bottom, and the external air first enters the air intake chamber 6, Then enter the dust removal chamber 5 through the air intake chamber 6, carry out the dust removal work in the dust removal chamber 5, and finally enter the exhaust chamber 4 to be discharged.

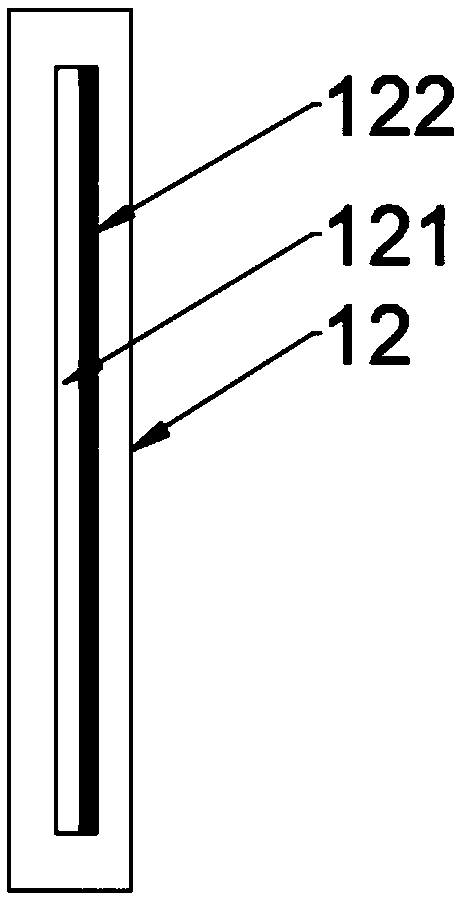

[0028] The left side of the upper partition 3 is provided with an air outlet 11, and the air outlet 11 is a tapered hole, and the lower partition 2 is provided with a dust discharge hole 9 and a communication ho...

Embodiment 2

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. A dust filter 8 is provided in the communicating hole 7, and the air is initially filtered through the dust filter 8, and the large particles of floating dust in the air are directly removed. Floating dust directly falls on the bottom wall of the air intake cavity 6 .

[0031] The top of the right end of the dust removal chamber 5 is provided with a deflector 13 matched with the communication hole 7, so that the air from the communication hole 7 moves to the left under the action of the deflector 13 and enters between the dust collecting plate 12. room, which is convenient for electrostatic dust removal of the air.

[0032] The top of the left end of the air intake chamber 6 is connected to the air intake pipe 14, the air intake pipe 14 is provided with a blower fan 15, and under the action of the blower fan 15, outside air is pulled into the air intake chamber 6 through the air intake pipe 14; The ...

Embodiment 3

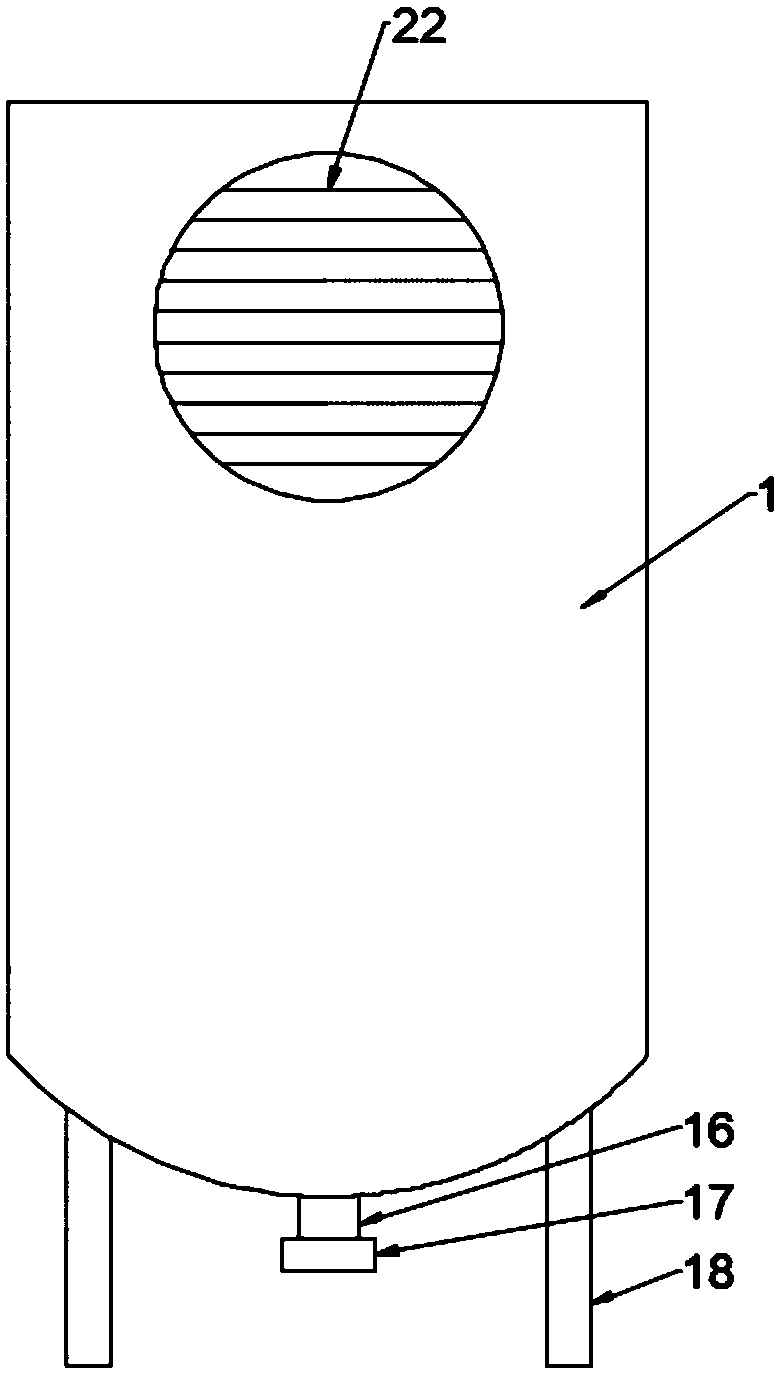

[0034] This embodiment is a further elaboration on the basis of Embodiment 1. The top of the right side of the air outlet chamber 4 is connected to the air outlet pipe 19, and the opening of the outer side of the air outlet pipe 19 is provided with a shutter 22. The left side of the inner cavity is provided with an exhaust fan 20, and the exhaust fan 20 is fixedly connected to the inner cavity wall of the air outlet pipe 19 through the connecting rod 21, and the exhaust fan 20 is started to draw the filtered air in the exhaust chamber 4 to pass through the air outlet pipe. 19 discharge.

[0035] The working principle of embodiment 1-3, under the effect of blower fan 15, pulls outside air to enter air intake cavity 6 through intake pipe 14, then enters dust removal cavity 5 through communication hole 7, and air realizes cleaning through dust filter net 8 in communication hole 7. The air is preliminarily filtered to directly remove large particles of floating dust in the air, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com