Method for producing distillers' grain powder and wheat enzyme paste by using wheat distillers' grains

A technology of distiller's grain powder and wheat wine, which is applied in the direction of application, additional food elements, animal feed, etc., to achieve the effect of increasing the crude protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one: Utilize wheat distiller's grains to produce distiller's grains powder and wheat ferment paste

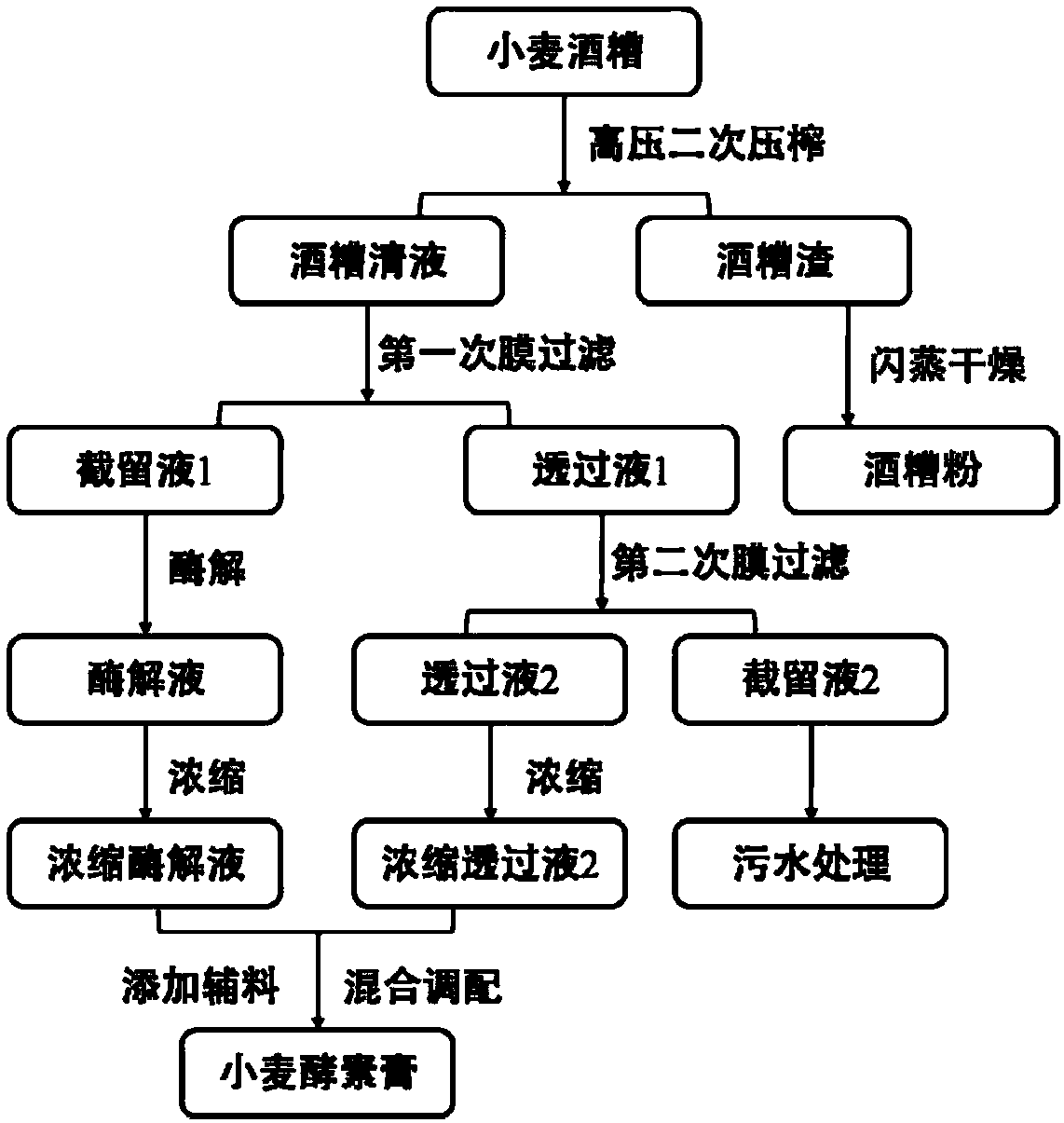

[0055] like figure 1 Shown, the technological process of utilizing wheat distiller's grains to produce distiller's grains powder and wheat enzyme paste is as follows.

[0056] S1. Obtain wheat distiller's grains raw material: wheat distiller's grains is wheat flour slurry fermented ethanol, the concentrated wheat distiller's grains is viscous, the color is tan or dark brown, the solid content is 25-35%, and the crude protein content (dried) 20-25%, the total sugar content (dry basis) is 35-40%, the total acid content (dry basis) is 10-15%, and the vomitoxin content (dry basis)>3ppm;

[0057] S2, 100 tons of wheat distiller's grains raw material (solid content 30%), carry out solid-liquid separation through high-pressure secondary press, obtain 50 tons of distiller's grains (solid content 45%) and 50m of distiller's grain clear liquid after separation 3 (soli...

Embodiment 2

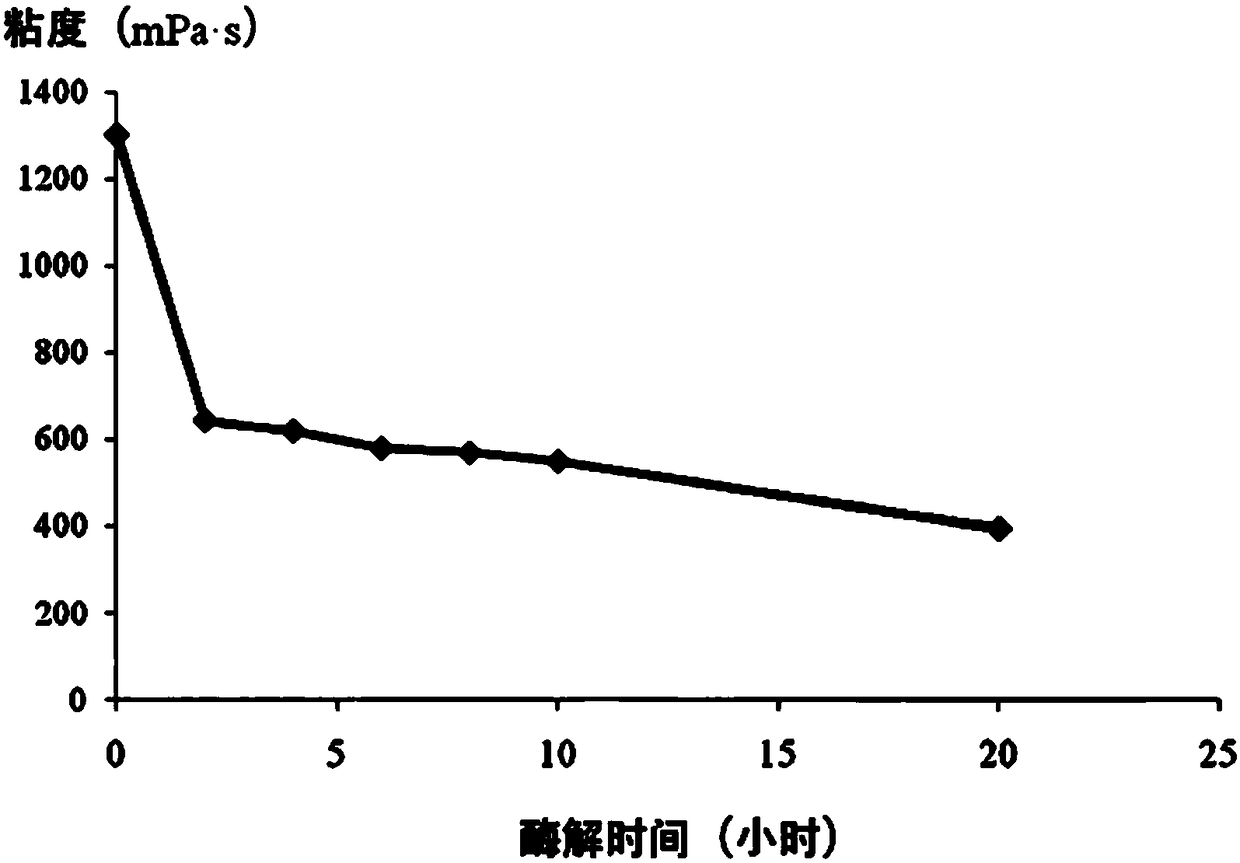

[0065] Example 2: Effects of hemicellulase, pectinase, and β-glucanase on the viscosity of wheat distiller's grains

[0066] Take 3000g of wheat distiller's grain raw material (30% of solid content), add 3000g of water to dilute and stir evenly, and prepare distiller's grain material with 15% of solid content. Hemicellulase, 50,000 U / g pectinase, and 50,000 U / g β-glucanase were added at 0.05% of the solid content. Stir well after adding the enzyme, and place it in a water bath at 50°C to carry out the enzymolysis reaction. When the enzymolysis reaction is 0 hour, 2 hours, 4 hours, 8 hours, 10 hours, and 20 hours, the enzymolysis materials are taken for viscosity detection. Viscosity detection adopts a digital display electronic viscometer, the detection rotor is the No. 2 rotor, and the detection speed is 6 rpm. The detection results of the viscosity of wheat distiller's grains changing with enzymatic hydrolysis time are as follows: figure 2 shown.

[0067] like figure ...

Embodiment 3

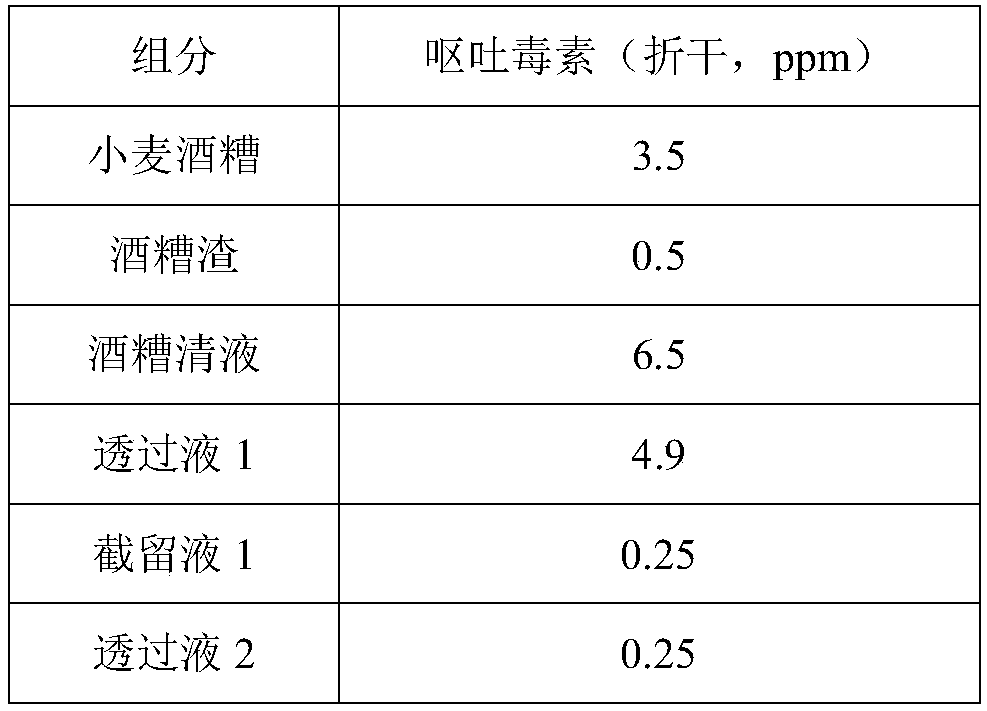

[0068] Embodiment three: the concentration comparison of vomitoxin of each component

[0069] Wheat distiller's grain raw material, distiller's grains, distiller's grain clear liquid, permeate 1, permeate 2, retentate 1, and retentate 2 were used to detect the concentration of vomitoxin. The detection method adopts the DON competitive inhibition colloidal gold rapid detection card, and the detection results are shown in Table 2.

[0070] Table 2 Test results of vomitoxin concentration

[0071]

[0072]

[0073] From the test results shown in Table 2, it can be seen that after wheat distiller's grains are subjected to high-pressure secondary pressing and secondary nanofiltration membrane filtration, most of the vomitoxin enters the retentate 2, and finally collects in the retentate 2 and enters the sewage treatment system Medium discharge, convenient for further processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com