A modified silicate aluminate additive for lithium sulfur battery electrolyte and a preparation method thereof

A technology of aluminosilicate and lithium-sulfur batteries, which is applied in the field of modified aluminosilicate additives and preparations of lithium-sulfur battery electrolytes, can solve problems such as difficulty in dissolving lithium polysulfide, achieve improved long-cycle performance, and have a simple method , the effect of stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

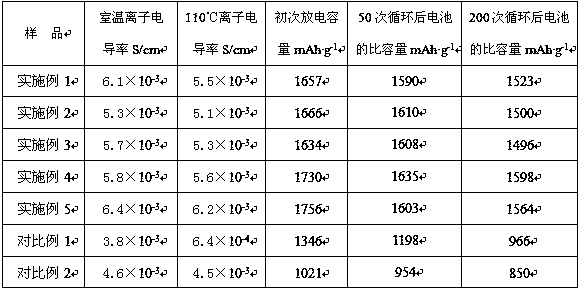

Examples

Embodiment 1

[0027] (1) Weigh 10 parts by mass of sodium metaaluminate, 9 parts by mass of sodium hydroxide, and 16 parts by mass of water glass solution with a mass concentration of 16%, add sodium metaaluminate and sodium hydroxide to the water glass solution and heat and stir , the stirring temperature is 75°C, the stirring speed is 60rpm, until the solution is completely clear, the clear solution is transferred to a polytetrafluoroethylene airtight container for aging, the aging pressure is 0.8MPa, the aging temperature is 180°C, and the aging is 24h , to obtain a Y-type zeolite molecular sieve precursor;

[0028] (2) Dissolve cetyltrimethylammonium bromide (CTAB) in deionized water at a mass ratio of 22:100, then add ammonia water with an excess concentration of 15% and the precursor solution prepared in step A, slowly drop Add 10% sulfuric acid solution until the pH is 9-10, control the dropping rate to 15mL / min, stir slowly for 4 hours, place the solution in a closed container, crys...

Embodiment 2

[0032] (1) Weigh 13 parts by mass of sodium metaaluminate, 8 parts by mass of sodium hydroxide, and 19 parts by mass of water glass solution with a mass concentration of 11%, add sodium metaaluminate and sodium hydroxide to the water glass solution for heating and stirring , the stirring temperature is 85°C, the stirring speed is 50rpm, until the solution is completely clear, the clear solution is transferred to a polytetrafluoroethylene airtight container for aging, the aging pressure is 1.5MPa, the aging temperature is 160°C, and aging for 24h , to obtain a Y-type zeolite molecular sieve precursor;

[0033] (2) Dissolve cetyltrimethylammonium bromide (CTAB) in deionized water at a mass ratio of 17:100, then add ammonia water with an excess concentration of 14% and the precursor solution prepared in step A, slowly drop Add 10% sulfuric acid solution until the pH is 9-10, control the dropping rate to 20mL / min, stir slowly for 4 hours, place the solution in a closed container, ...

Embodiment 3

[0037] (1) Weigh 8 parts by mass of sodium metaaluminate, 10 parts by mass of sodium hydroxide, and 14 parts by mass of water glass solution with a mass concentration of 11%, add sodium metaaluminate and sodium hydroxide to the water glass solution for heating and stirring , the stirring temperature is 67°C, the stirring speed is 85rpm, until the solution is completely clear, the clear solution is transferred to a polytetrafluoroethylene airtight container for aging, the aging pressure is 1.0MPa, the aging temperature is 180°C, and aging for 24h , to obtain a Y-type zeolite molecular sieve precursor;

[0038] (2) Dissolve cetyltrimethylammonium bromide (CTAB) in deionized water at a mass ratio of 20:100, then add ammonia water with an excess concentration of 17% and the precursor solution prepared in step A, slowly drop Add 10% sulfuric acid solution until the pH is 9-10, control the dropping rate to 10mL / min, stir slowly for 4.5h, put the solution in a closed container, cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com