A kind of lithium-ion battery aging capacity classification method

A lithium-ion battery, battery technology, applied in secondary batteries, electrochemical generators, secondary battery repair/maintenance, etc., can solve the problems of wasteful capacity dividing equipment production efficiency, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

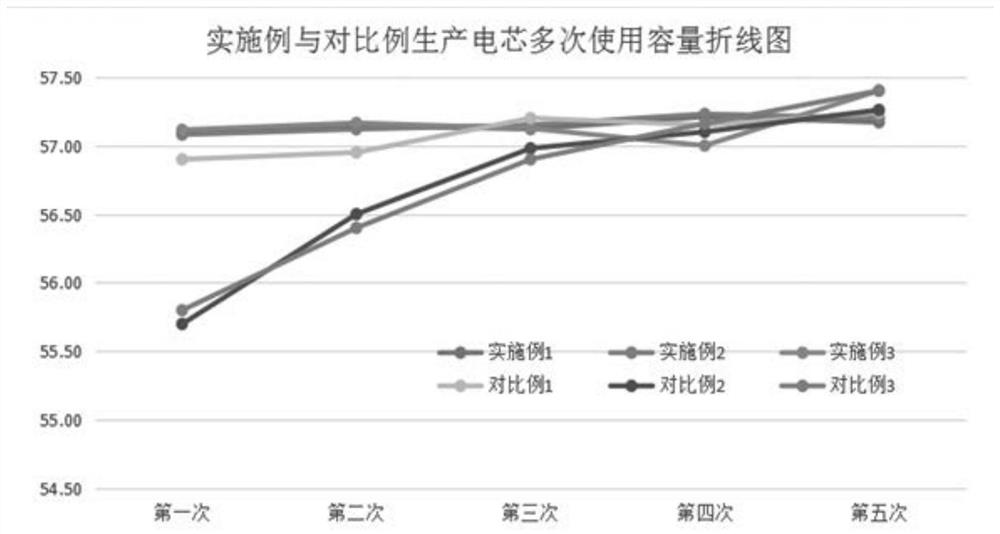

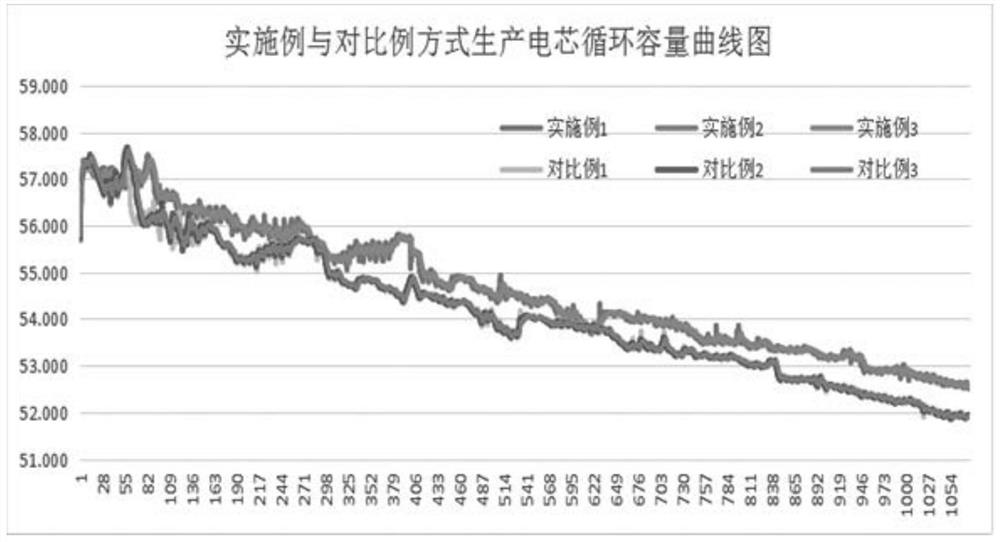

Embodiment 1

[0029] The lithium-ion battery aging capacity classification method comprises the following steps:

[0030] S1. Aging at 40°C for 18h after battery injection and sealing;

[0031] S2, constant current and constant voltage 1C charge to 3.65V cut-off current 0.2C, then aging at 45°C for 18h;

[0032] S3, constant current 1C discharge for 10min;

[0033] S4, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0034] S5, constant current 1C discharge to 1.85V;

[0035] S6, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0036] S7, constant current 1C discharge to 2.5V;

[0037] S8, constant current 0.3C discharge to 2V, constant current 0.02C discharge to 2V;

[0038] S9, constant current 0.2C charging for 30min. That is, a lithium-ion battery with capacity separation is obtained.

Embodiment 2

[0040] The lithium-ion battery aging capacity classification method comprises the following steps:

[0041] S1. Aging at 50°C for 18 hours after battery injection and sealing;

[0042] S2, constant current and constant voltage 1C charge to 3.65V cut-off current 0.2C, then aging at 50°C for 18h;

[0043] S3, constant current 1C discharge for 10min;

[0044] S4, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0045] S5, constant current 1C discharge to 1.9V;

[0046] S6, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0047] S7, constant current 1C discharge to 2.5V;

[0048] S8, constant current 0.3C discharge to 2V, constant current 0.02C discharge to 2V;

[0049] S9. Charging at a constant current of 0.2C for 30 minutes; that is, a lithium-ion battery with capacity division is obtained.

Embodiment 3

[0051] The lithium-ion battery aging capacity classification method comprises the following steps:

[0052] S1. Aging at 50°C for 18 hours after battery injection and sealing;

[0053] S2, constant current and constant voltage 1C charge to 3.65V cut-off current 0.2C, then aging at 50°C for 18h;

[0054] S3, constant current 1C discharge for 5min;

[0055] S4, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0056] S5, constant current 1C discharge to 2.5V;

[0057] S6, constant current constant voltage 1C charging to 3.65V cut-off current 0.2C;

[0058] S7, constant current 1C discharge to 2.5V;

[0059] S8, constant current 0.3C discharge to 2V, constant current 0.02C discharge to 2V;

[0060] S9, constant current 0.2C charging for 30min. That is, a lithium-ion battery with capacity separation is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com