Rapid drying equipment in textile fabric production process

A production process, fast drying technology, applied in drying, dryer, lighting and heating equipment, etc., can solve the problems affecting the appearance quality of textile cloth, single function, deformation of textile cloth and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

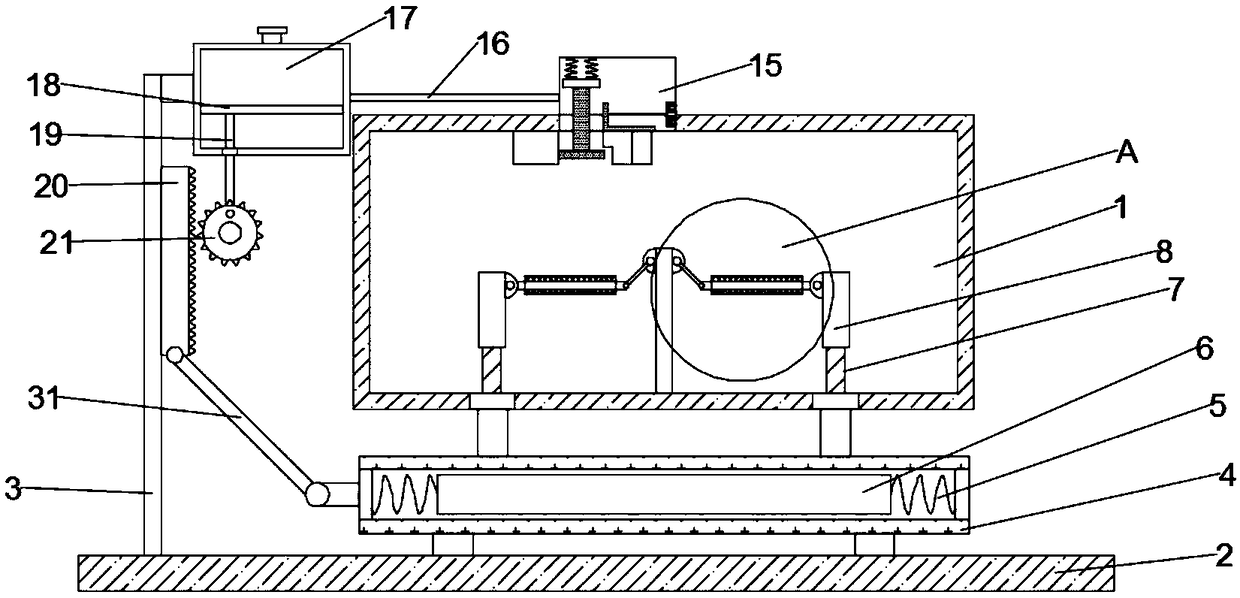

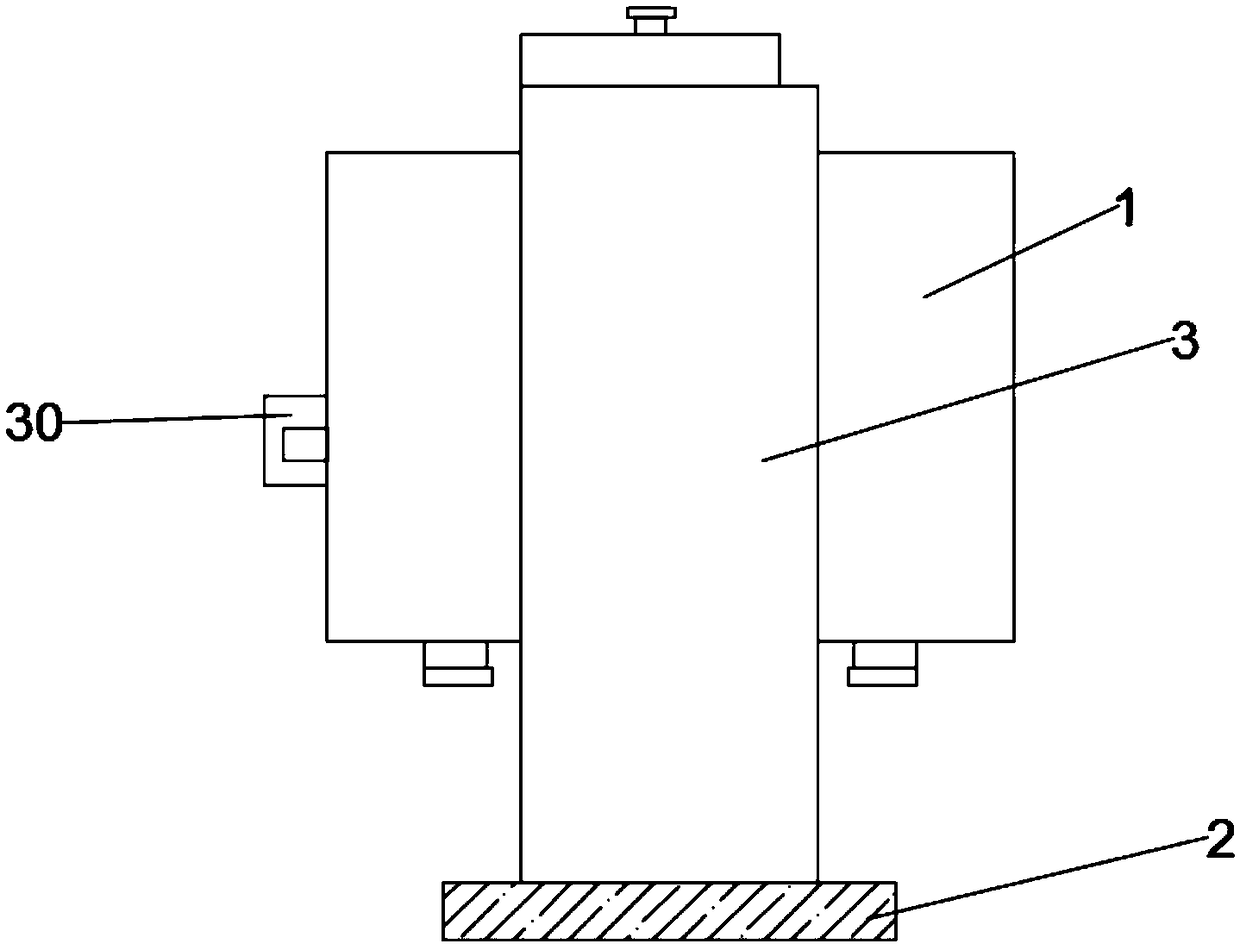

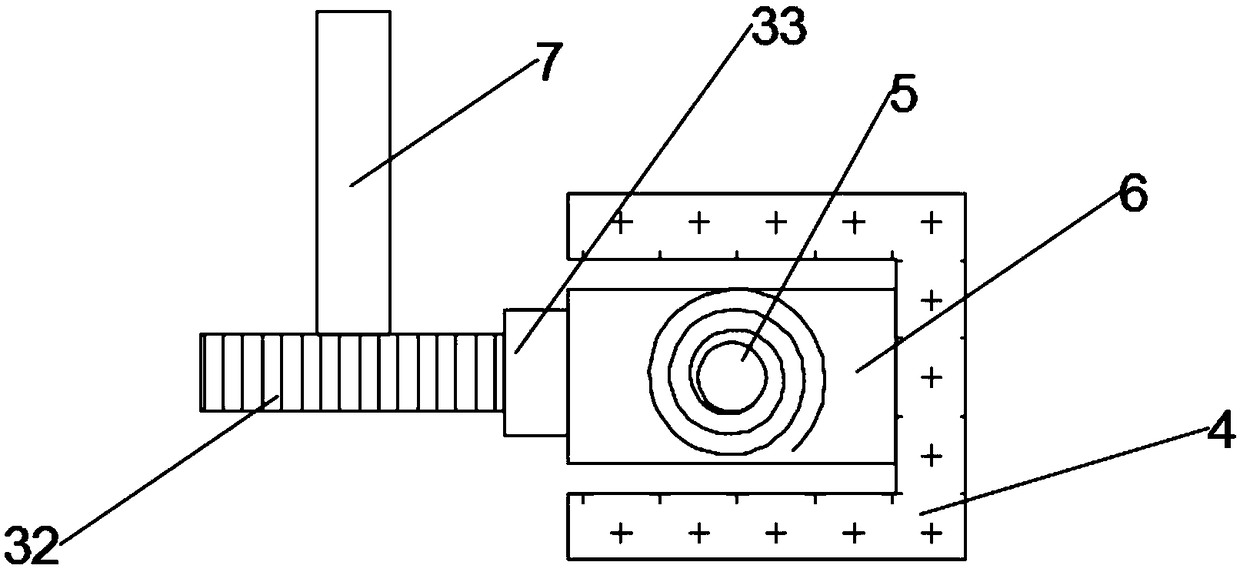

[0021] see Figure 1~4 , in an embodiment of the present invention, a kind of rapid drying equipment in the production process of textile fabrics, including a drying box 1, a supporting base 2, a supporting column 3, a horizontal chute 4 and a vapor compression chamber 17, after the drying box 1 The entrance 30 is set at the middle position of the side, the air outlets are set on both sides of the bottom surface of the drying box 1, two placement plates 10 are arranged inside the drying box 1, and the upper left side of the drying box 1 is fixedly connected to the vapor compression chamber 17. The left side of the vapor compression chamber 17 is fixed on the support column 3, and the lower end of the support column 3 is fixed with a welding support base 2, and the support base 2 is horizontally arranged under the drying box 1, and the drying box A horizontal chute 4 is arranged in parallel between 1 and the support base 2;

[0022] The right side wall of the support column 3 ...

Embodiment 2

[0027] Such as Figure 5 As shown, in this embodiment, a steam discharge device 15 is provided between the guide pipe 16 and the inner cavity of the drying box 1, and the left side wall of the steam discharge device 15 communicates with the guide pipe 16. Two second buffer springs 25 are arranged on the left side of the inner cavity top of the steam discharge device 15, the upper end of the second buffer spring 25 is fixedly welded to the upper wall of the steam discharge device 15, and the lower end of the second buffer spring 25 is fixedly welded to the first connection Rod 22, the first connecting rod 22 is vertically arranged, the first diversion opening 24 is arranged at a corresponding position below the first connecting rod 22, and the lower end of the first connecting rod 22 is fixedly connected to the sealing plug 23, the A gap is set between the sealing plug 23 and the right side wall of the first diversion opening 24, and when the steam flow rate is small, the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com