Separable vacuum interconnected system

An interconnection system and separate technology, applied in the field of vacuum interconnection instruments, can solve the problems of increased transmission burden, the danger of trolley derailment, large footprint of vacuum interconnection devices, and inflexibility of large interconnection devices, so as to achieve interconnection and compatibility. Enhanced networking and convenience, less demand for interior space and load-bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

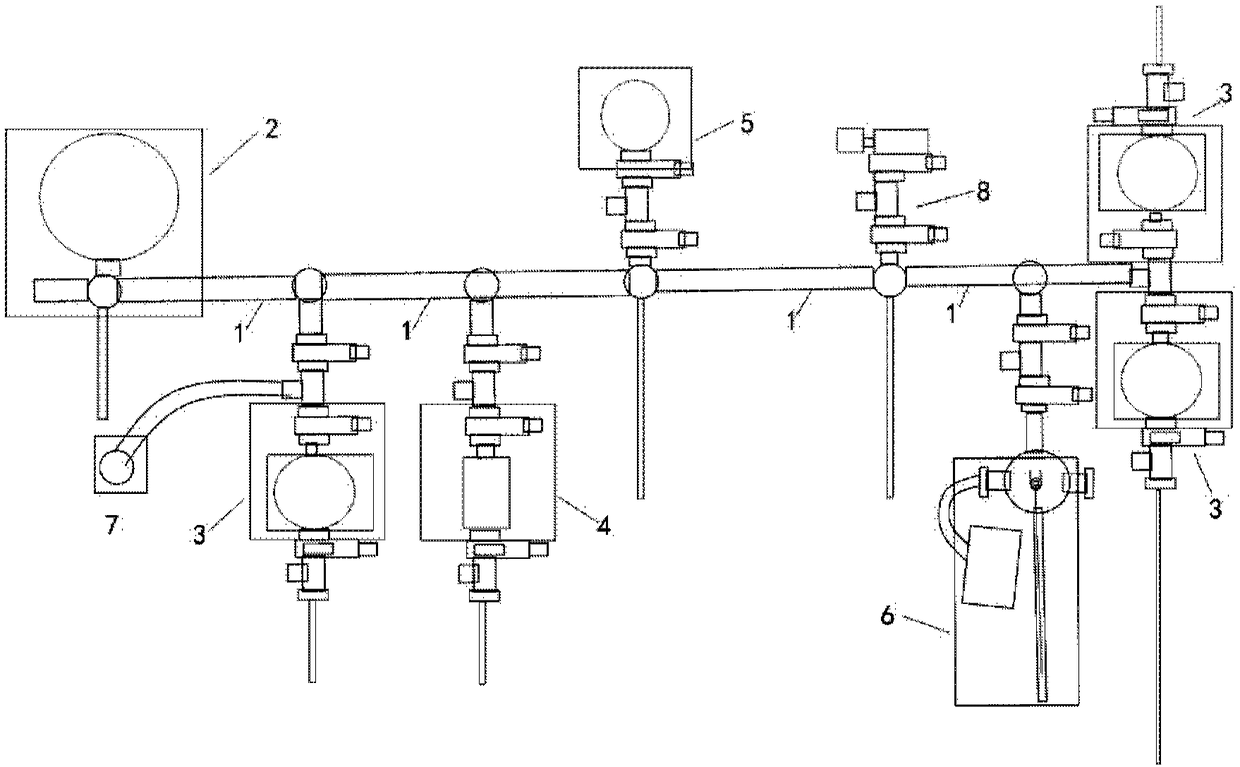

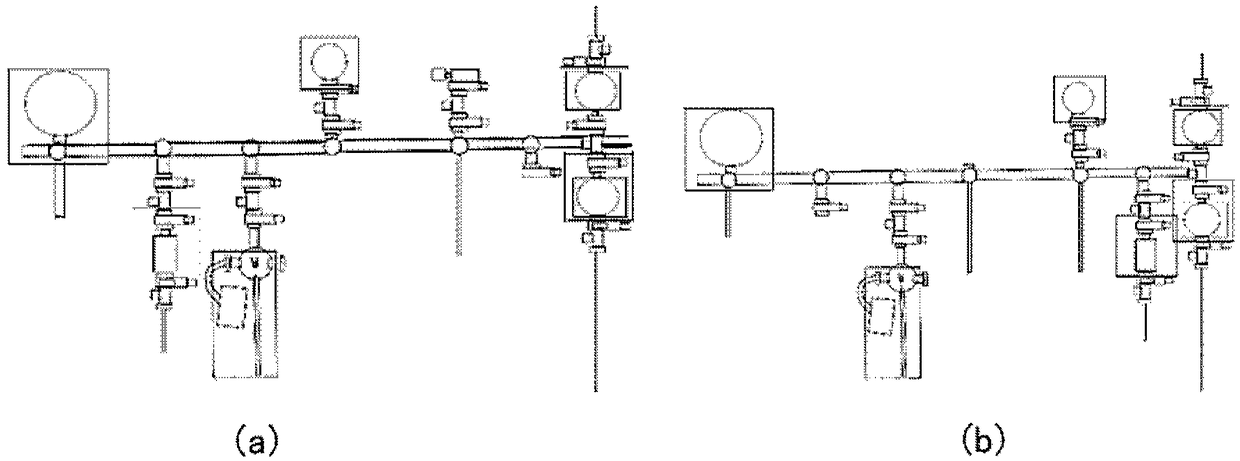

[0065] The present disclosure provides a detachable vacuum interconnection system, which includes: a main interconnection pipeline, a main interconnection device, a plurality of movable split devices, and an integrated constant temperature platform, and a plurality of movable The split device can be connected and disassembled on the main interconnection pipeline, and can be connected and separated from the main interconnection fixing device. At the same time, multiple split devices can be used alone or in any combination to form an integrated cavity. The equipment for material growth, testing and sample transfer can be adjusted according to the needs of the experiment and the spatial distribution of the site. It is flexible and convenient, and each split device has a small footprint and has a small demand for indoor space and load-bearing. Better security; and realize in-situ sample transfer, long-distance transportation of samples at a specific temperature and cross-border tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com