Environmentally-friendly fireproof coating and preparation method thereof

A fire-resistant coating and environmental protection technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor stability of coatings and damage to the health of firefighters, and achieve good stability and good fire-retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

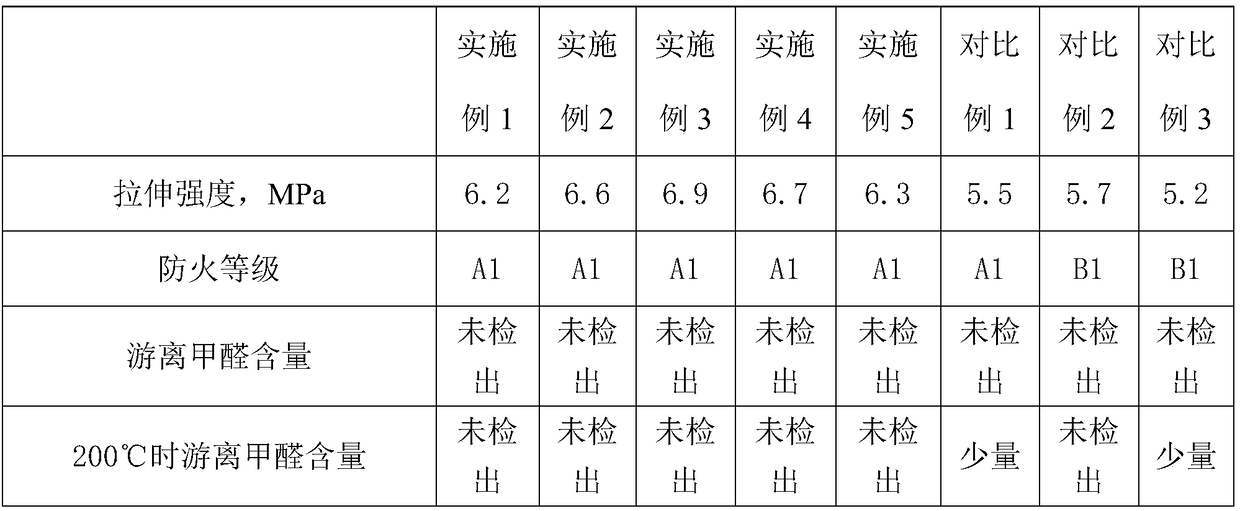

Examples

Embodiment 1

[0021] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 30 parts of acrylic emulsion, 5 parts of epoxy resin, 5 parts of aluminum hydroxide, 3 parts of zinc borate, 3 parts of kaolin, 2 parts of sepiolite, vitrified microspheres 1 part, 1 part of graphene oxide, 1 part of diaminodiphenyl sulfone, 1 part of nonylphenol polyoxyethylene ether, 5 parts of inflorescences of Erythrizum officinalis, 2 parts of adhesive agent, 30 parts of deionized water.

[0022] Wherein, the acrylic emulsion components include pure acrylic emulsion, silicone acrylic emulsion, and vinegar acrylic emulsion.

[0023] Wherein, the weight ratio of pure acrylic emulsion, silicon-acrylic emulsion and vinegar-acrylic emulsion in the acrylic emulsion is 3:5:2.

[0024] In the present embodiment, the preparation method of described environment-friendly fireproof coating, the steps are as follows:

[0025] 1) Adding 10 times the weight of water to the i...

Embodiment 2

[0030] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 35 parts of acrylic emulsion, 7 parts of epoxy resin, 6 parts of aluminum hydroxide, 3.5 parts of zinc borate, 3.5 parts of kaolin, 2.2 parts of sepiolite, vitrified microbeads 1.2 parts, 1.5 parts of graphene oxide, 2.5 parts of diaminodiphenyl sulfone, 1.8 parts of nonylphenol polyoxyethylene ether, 9 parts of inflorescences of Erythronia chinensis, 2.8 parts of adhesive agent, 45 parts of deionized water.

[0031] Wherein, the acrylic emulsion components include pure acrylic emulsion, silicone acrylic emulsion, and vinegar acrylic emulsion.

[0032] Wherein, the weight ratio of pure acrylic emulsion, silicon-acrylic emulsion and vinegar-acrylic emulsion in the acrylic emulsion is 3:5:2.

[0033] In the present embodiment, the preparation method of described environment-friendly fireproof coating, the steps are as follows:

[0034] 1) Adding 12 times the weight o...

Embodiment 3

[0039] An environmentally friendly fireproof coating, comprising the following raw materials in parts by weight: 40 parts of acrylic emulsion, 8 parts of epoxy resin, 7 parts of aluminum hydroxide, 4 parts of zinc borate, 4 parts of kaolin, 2.5 parts of sepiolite, vitrified microspheres 1.5 parts, 2 parts of graphene oxide, 2 parts of diaminodiphenyl sulfone, 1.5 parts of nonylphenol polyoxyethylene ether, 8 parts of inflorescences of Erythronia sativa, 2.5 parts of adhesive agent, 40 parts of deionized water.

[0040] Wherein, the acrylic emulsion components include pure acrylic emulsion, silicone acrylic emulsion, and vinegar acrylic emulsion.

[0041] Wherein, the weight ratio of pure acrylic emulsion, silicon-acrylic emulsion and vinegar-acrylic emulsion in the acrylic emulsion is 3:5:2.

[0042] In the present embodiment, the preparation method of described environment-friendly fireproof coating, the steps are as follows:

[0043] 1) Adding 12 times the weight of water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com