A kind of high-strength anti-crack gypsum board and preparation method thereof

A gypsum board, high-strength technology, applied in the field of building materials, can solve problems such as hidden safety hazards of building decoration, affecting building appearance, gypsum material falling off, etc., and achieve the effects of long service life, wide source of raw materials, and enhanced mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

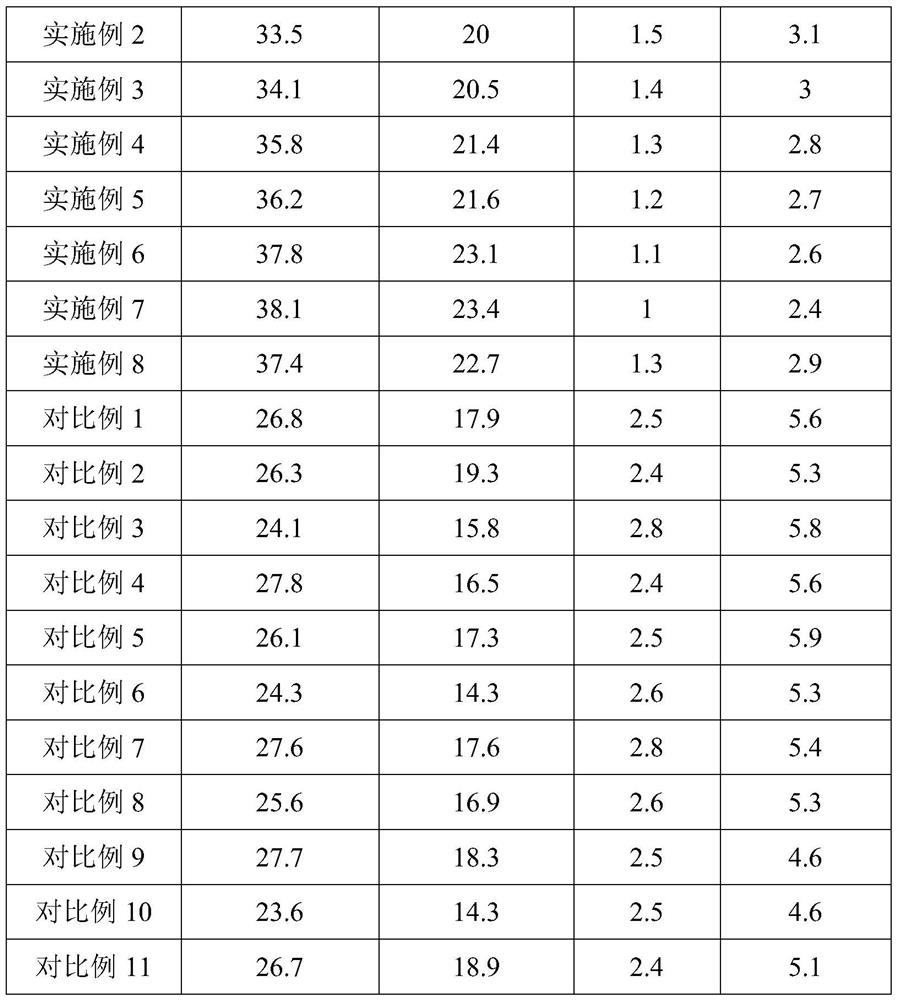

Examples

preparation example Construction

[0031] In some embodiments, the preparation method of the chitosan oligosaccharide modified alumina fiber comprises:

[0032] (1) 20g crystalline aluminum chloride AlCl 3 ·6H 2 O was dissolved in 100g of distilled water, then 10g of metal aluminum powder was added and heated under reflux at 90°C for 6h, the solution became clear and transparent, and then 0.5g of silica sol was added to the above transparent solution as a spinning aid, and after it was completely dissolved, the The above solution was concentrated under an atmosphere of -0.09MPa and 80°C to obtain alumina spinning sol, and the spinning sol was injected into the spinning die through a micro-injection pump for drawing to obtain self-made alumina fibers.

[0033] (2) The self-made alumina fiber and chitosan oligosaccharide were mixed and placed in a mixer for stirring at a stirring temperature of 75° C. for 2 hours to obtain chitosan oligosaccharide modified alumina fiber.

[0034] In a preferred embodiment, the ...

Embodiment 1

[0079]Embodiment 1 provides a kind of high-strength anti-cracking gypsum board. In parts by weight, the preparation raw materials include: 20 parts of building gypsum powder, 10 parts of modified alumina fiber, 1 part of fly ash, 2 parts of montmorillonite, 1 part of 1 part foaming agent, 1 part calcium oxide expansion agent, 1 part retarder, 1 part modified silicone, 6 parts deionized water.

[0080] The building gypsum powder was purchased from Tai'an Jiepu Gypsum Technology Co., Ltd.

[0081] The modified alumina fiber is chitosan oligosaccharide modified alumina fiber, and the preparation method comprises:

[0082] (1) 20g crystalline aluminum chloride AlCl 3 ·6H 2 O was dissolved in 100g of distilled water, then 10g of metal aluminum powder was added and heated under reflux at 90°C for 6h, the solution became clear and transparent, and then 0.5g of silica sol was added to the above transparent solution as a spinning aid, and after it was completely dissolved, the The a...

Embodiment 2

[0107] Embodiment 2 provides a kind of high-strength anti-crack gypsum board, by weight, preparation raw material comprises: 40 parts of construction gypsum powder, 20 parts of modified alumina fibers, 6 parts of fly ash, 8 parts of montmorillonite, 3 parts of Part foaming agent, 5 parts calcium oxide expansion agent, 6 parts retarder, 8 parts modified silicone, 10 parts deionized water.

[0108] The building gypsum powder was purchased from Tai'an Jiepu Gypsum Technology Co., Ltd.

[0109] The modified alumina fiber is chitosan oligosaccharide modified alumina fiber, and the preparation method is the same as in Example 1, except that the alumina fiber and the chitosan oligosaccharide in the chitosan oligosaccharide modified alumina fiber are The weight ratio is 1:0.3.

[0110] The fly ash was purchased from Xuancheng Shuangle Renewable Resources Co., Ltd.

[0111] The montmorillonite was purchased from Anhui Benrun Mining Technology Co., Ltd.

[0112] The foaming agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com