Environmental-friendly flame-retardant antibacterial fiberboard for reinforced wood floor

A technology of laminated wood flooring and antibacterial fiber, applied in the field of materials, can solve problems such as easy deformation, peculiar smell, breeding bacteria, etc., and achieve the effect of reducing effective combustion heat and mass loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

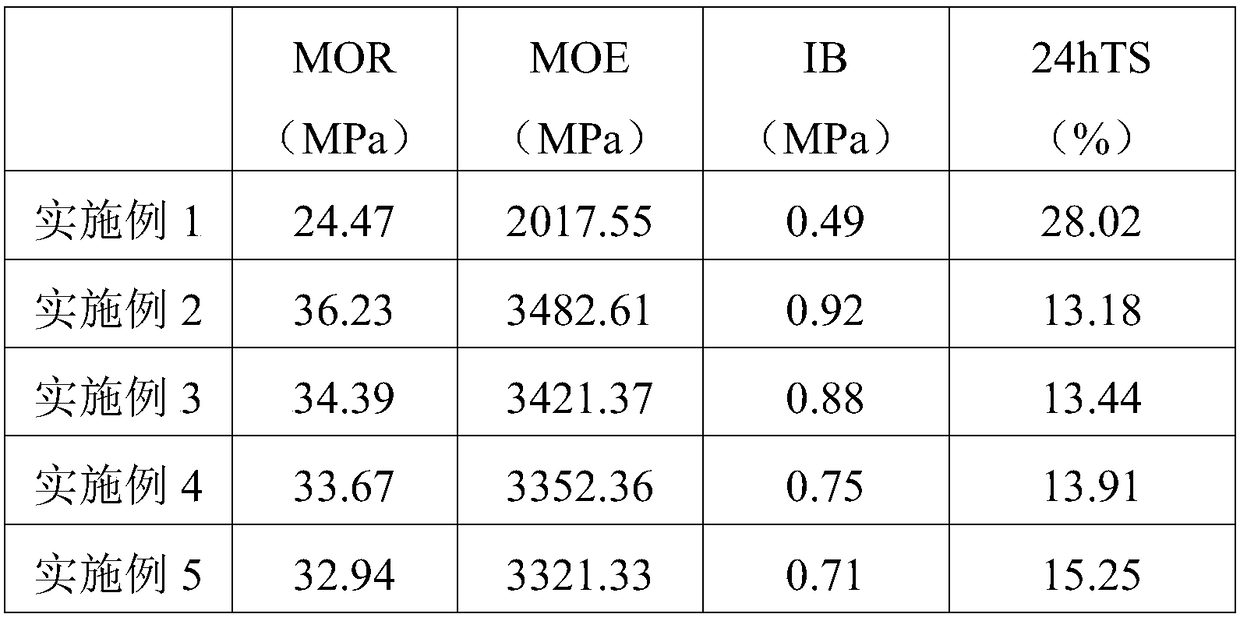

Examples

Embodiment 1

[0067] An environmentally friendly flame-retardant and antibacterial fiberboard for laminate flooring, the preparation process of which comprises the following steps:

[0068] The first step, wood fiber is dried to moisture content 10wt%;

[0069] In the second step, the dried wood fiber is put into a high-speed mixer and stirred at 1500 rpm for thinning for 1 minute to obtain thinned wood fiber;

[0070] The third step is to mix the thinned wood fiber and 3% of its weight of nano-bentonite evenly, pave it into the mold, pre-press it through a pre-press, and cut off the burrs to obtain a slab;

[0071] The fourth step is to heat-press the slab using a hot-press machine, with a hot-pressing pressure of 4 MPa and a temperature of 170°C. After hot-pressing for 4 minutes, stop the hot-pressing;

[0072] The fifth step is to place the hot-pressed board in an indoor environment of 20° C. for 15 days to obtain the environmentally friendly flame-retardant and antibacterial fiber boar...

Embodiment 2

[0074] An environmentally friendly flame-retardant and antibacterial fiberboard for laminate flooring, the preparation process of which comprises the following steps:

[0075] In the first step, wood fibers are treated with magnetically immobilized laccase;

[0076] In the second step, the wood fiber treated with magnetically immobilized laccase is dried to a moisture content of 10wt%;

[0077] In the third step, the dried wood fibers are put into a high-speed mixer and stirred at 1500 rpm for thinning for 1 minute to obtain thinned wood fibers;

[0078] The fourth step is to mix the thinned wood fiber and 3% of its weight of nano-bentonite evenly, pave it into the mold, pre-press it through a pre-press, and cut off the burr to obtain a slab;

[0079] The fifth step is to heat-press the slab with a hot-pressing machine, the hot-pressing pressure is 4MPa, the temperature is 170°C, and after hot-pressing for 4 minutes, stop the hot-pressing;

[0080] The sixth step is to place...

Embodiment 3

[0087] An environmentally friendly flame-retardant and antibacterial fiberboard for laminate flooring, the preparation process of which comprises the following steps:

[0088] In the first step, wood fibers are treated with magnetically immobilized laccase;

[0089] In the second step, the wood fiber treated with magnetically immobilized laccase is dried to a moisture content of 10wt%;

[0090] In the third step, the dried wood fibers are put into a high-speed mixer and stirred at 1500 rpm for thinning for 1 minute to obtain thinned wood fibers;

[0091] The fourth step is to mix the thinned wood fiber and 3% of its weight of nano-bentonite evenly, pave it into the mold, pre-press it through a pre-press, and cut off the burr to obtain a slab;

[0092] The fifth step is to heat-press the slab with a hot-pressing machine, the hot-pressing pressure is 4MPa, the temperature is 170°C, and after hot-pressing for 4 minutes, stop the hot-pressing;

[0093] The sixth step is to place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com