Using method of wet-on-wet water-based double-component coating

A water-based two-component, coating technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problems of difficulty in wet spraying and low production efficiency, etc. To achieve the effect of reducing excessive time, improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

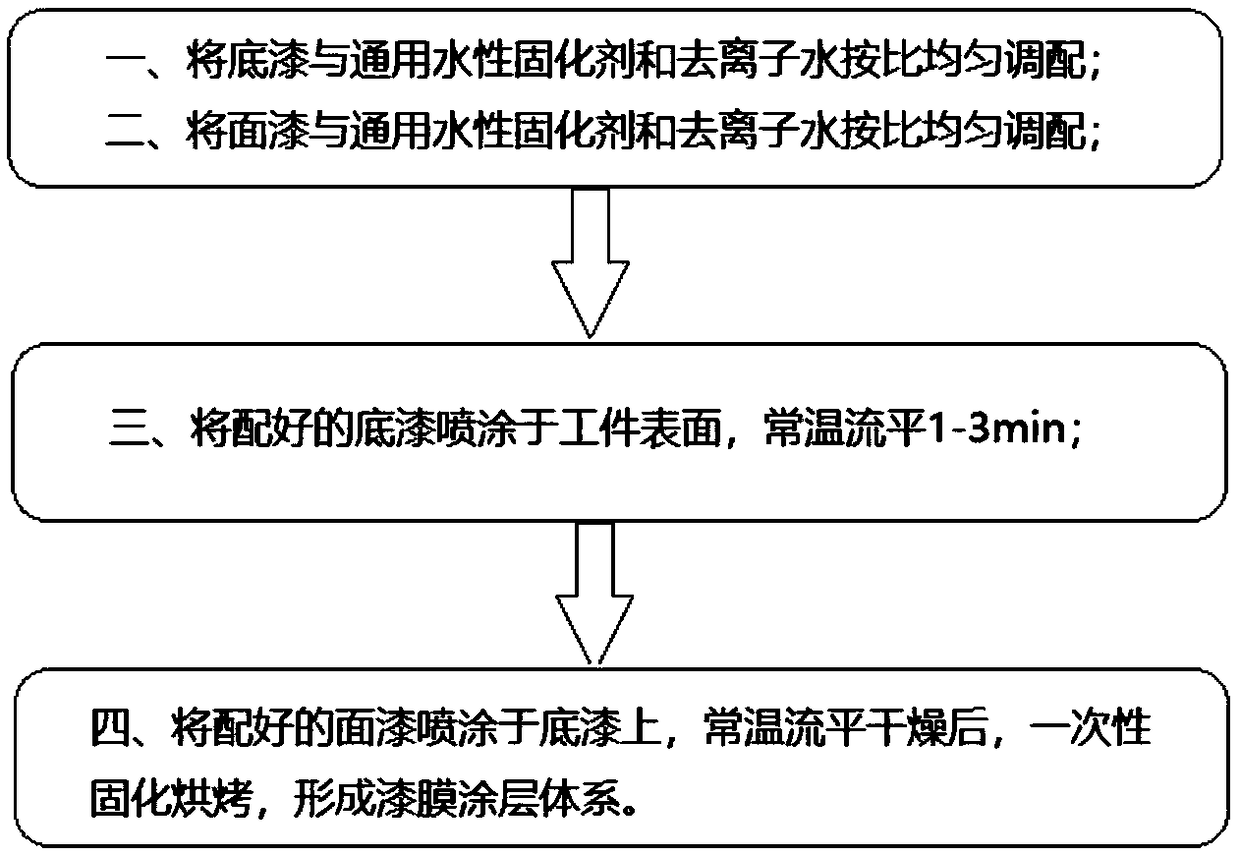

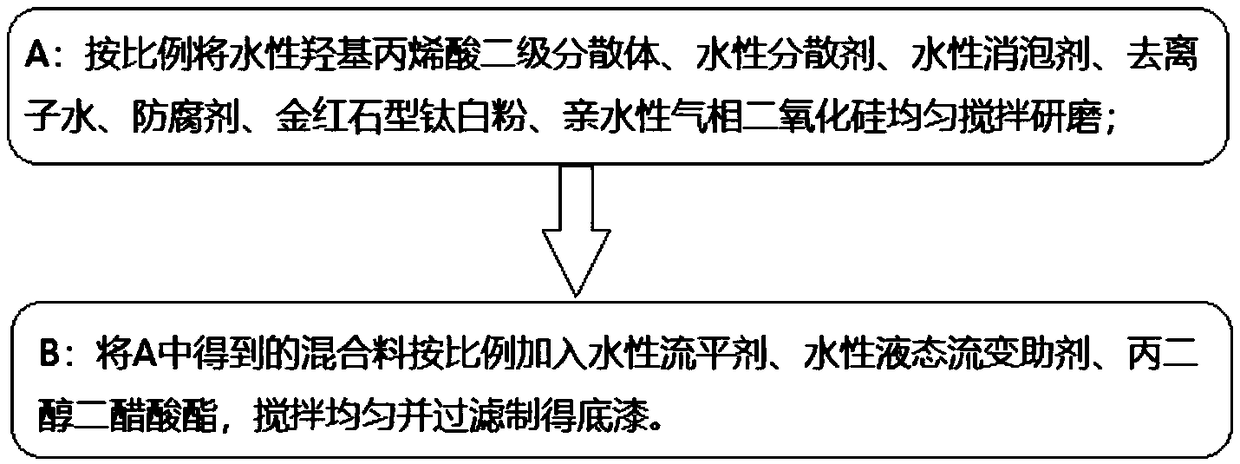

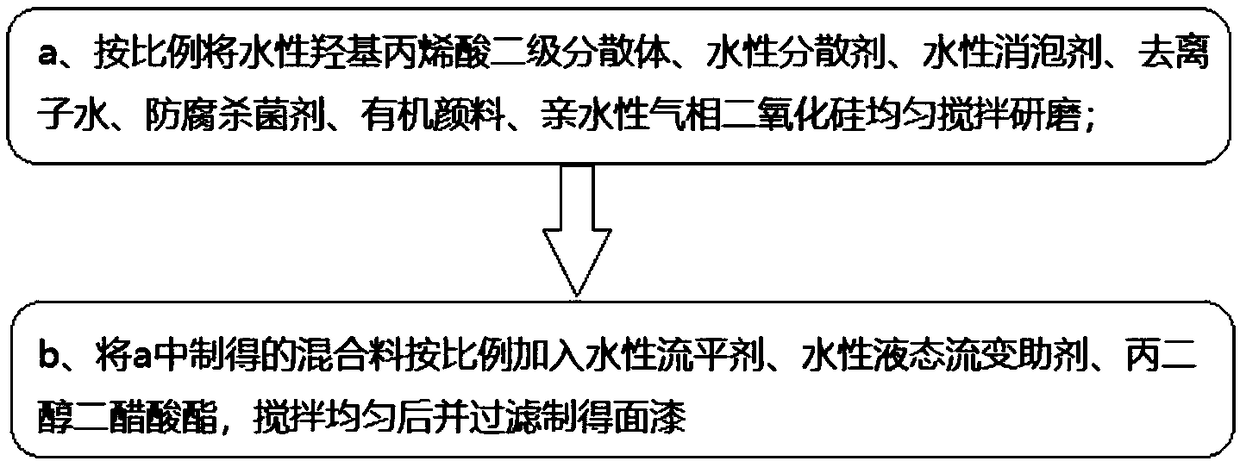

[0042] Such as Figure 1-Figure 3 Shown, the using method of a kind of wet spray wet waterborne two-component coating of the present embodiment, carry out according to the following steps:

[0043] Step 1. Evenly mix the primer with general water-based curing agent and deionized water according to 4:1:1;

[0044] Step 2. Evenly mix the topcoat with the universal water-based curing agent and deionized water according to the ratio of 3:1:1;

[0045] Step 3. Spray the prepared primer on the surface of the workpiece, leveling at room temperature for 1 minute;

[0046] Step 4: Spray the prepared topcoat on the primer layer, level and dry the two coats at room temperature for 20 minutes; then cure and bake at 75°C for 25 minutes to form a paint film coating system.

[0047] Wherein step 1 and step 2 have no sequence requirements, the general water-based curing agent used is a water-based isocyanate curing agent, specifically including the following raw materials in parts by weight: ...

Embodiment 2

[0063] A method for using a wet-sprayed wet water-based two-component coating in this embodiment, the primer and the topcoat are used together, specifically, the primer is evenly prepared with a general-purpose water-based curing agent and deionized water according to 3: 2: 1; The topcoat, general water-based curing agent and deionized water are evenly prepared according to 2:1:1, and the prepared primer is sprayed on the surface of the workpiece. After leveling at room temperature for 3 minutes, the prepared topcoat is sprayed on the primer layer. The two coatings were leveled and dried at room temperature for 30 minutes; then cured and baked at 85°C for 35 minutes to form a paint film coating system.

[0064] Wherein the general water-based curing agent used is a water-based isocyanate curing agent, specifically comprising the following raw materials in parts by weight: 40 parts based on IPDI hydrophilic modified aliphatic polyisocyanate; 40 parts based on HDI hydrophilic mod...

Embodiment 3

[0078] A method for using a wet-sprayed wet water-based two-component coating in this embodiment, the primer and the topcoat are used together, specifically, the primer is evenly prepared with a general-purpose water-based curing agent and deionized water according to 5: 2: 1; The topcoat, general water-based curing agent and deionized water are evenly prepared according to 4:2:1, and the prepared primer is sprayed on the surface of the workpiece. After leveling at room temperature for 2 minutes, the prepared topcoat is sprayed on the primer layer. The two coatings were leveled and dried at room temperature for 25 minutes; then cured and baked at 80°C for 30 minutes to form a paint film coating system.

[0079] Wherein the general water-based curing agent used is a water-based isocyanate curing agent, specifically including the following raw materials in parts by weight: 50 parts based on IPDI hydrophilic modified aliphatic polyisocyanate; 50 parts based on HDI hydrophilic modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com