Composite inhibitor for galena and application method thereof

A compound inhibitor and galena technology, applied in solid separation, flotation, etc., can solve the problems of high toxicity, difficult application, and high toxicity of cyanide method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

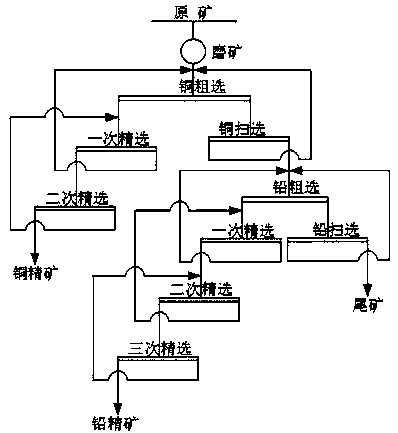

Image

Examples

Embodiment 1

[0016] In this example, a copper-lead polymetallic sulfide ore in Shaanxi is used as a ore sample. The raw ore contains Cu grade of 0.39%, primary copper sulfide occupancy rate is 58.97%, secondary copper sulfide occupancy rate is 30.24%, and Pb grade is 3.24%. Specifically, the following steps are included. :

[0017] In this embodiment, a composite inhibitor of galena is 11% by weight of ferric sulfate, 18% by weight of fatty alcohol polyoxyethylene ether, 13% by weight of glycerin, and 13% by weight of carboxymethyl cellulose. The pharmaceutical raw materials were weighed in a ratio of 26% by weight and 32% by weight of sodium silicate.

[0018] The use method of the composite inhibitor of the present embodiment, the specific steps are as follows:

[0019] (1) Under normal temperature conditions, the ferric sulfate, fatty alcohol polyoxyethylene ether, glycerin, carboxymethyl cellulose and sodium silicate weighed in proportion are respectively prepared into solutions with ...

Embodiment 2

[0024] In this example, a copper-lead polymetallic sulfide ore in Sichuan is used as a ore sample. The raw ore contains Cu grade of 0.41%, primary copper sulfide occupancy rate is 57.68%, secondary copper sulfide occupancy rate is 31.54%, and Pb grade is 3.61%. Specifically, the following steps are included. :

[0025] In the present embodiment, a composite inhibitor of galena is 10% by weight of ferric sulfate, 22% by weight of fatty alcohol polyoxyethylene ether, 17% by weight of glycerin, and 10% by weight of carboxymethyl cellulose. The pharmaceutical raw materials were weighed in a ratio of 20% by weight and 31% by weight of sodium silicate.

[0026] The use method of the composite inhibitor of the present embodiment, the specific steps are as follows:

[0027] (1) Under normal temperature conditions, the ferric sulfate, fatty alcohol polyoxyethylene ether, glycerin, carboxymethyl cellulose and sodium silicate weighed in proportion are respectively prepared into solution...

Embodiment 3

[0032] In this example, a copper-lead polymetallic sulfide ore in Yunnan is used as a ore sample. The raw ore contains Cu grade of 0.67%, primary copper sulfide occupancy rate is 55.67%, secondary copper sulfide occupancy rate is 28.57%, and Pb grade is 4.27%. Specifically include the following steps:

[0033] In this embodiment, a composite inhibitor of galena is 14% by weight of iron sulfate, 20% by weight of fatty alcohol polyoxyethylene ether, 15% by weight of glycerin, and 15% by weight of carboxymethyl cellulose. The pharmaceutical raw materials were weighed in a ratio of 25% by weight and 26% by weight of sodium silicate.

[0034] The use method of the composite inhibitor of the present embodiment, the specific steps are as follows:

[0035] (1) Under normal temperature conditions, the ferric sulfate, fatty alcohol polyoxyethylene ether, glycerin, carboxymethyl cellulose, and sodium silicate that were weighed in proportion were respectively prepared into solutions with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com