Method for preparing oil-water separation membrane from waste cigarette filter tip and application in oil-water separation

An oil-water separation membrane and oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as health and ecological environment hazards, can not be degraded by the environment, and achieve high emulsion separation flux, separation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cleaning of discarded cigarette filters: Peel off the outer paper of discarded cigarette filters, wash them with hot water for several times, and soak them in distilled water for 24 hours to remove pollutants on the surface of discarded cigarette filters; then, dry them at 60 °C for 6 hours to obtain clean cigarette filters;

[0036] Preparation of electrospinning solution: Dissolve clean waste cigarette filters in a mixed solution of DMF and acetone (the volume ratio of DMF and acetone is 1:0.3) to prepare an electrospinning solution with a concentration of 12.4 wt%.

[0037]Preparation of oil-water separation membrane: Using 300-mesh stainless steel wire mesh as the receiver (cleaned with acetone, ethanol, and deionized water, respectively), the oil-water separation membrane was prepared by electrospinning, marked as CFNM-300. During the spinning process, the voltage was maintained at 17 kV; the distance between the tip of the needle and the stainless steel wire mesh ...

Embodiment 2

[0040] The cleaning of discarded cigarette filter tip: with embodiment 1;

[0041] Preparation of electrospinning solution: Dissolve the cleaned waste cigarette filter in a mixed solution of DMF and acetone (the volume ratio of DMF and acetone is 1::0.4) to prepare an electrospinning solution with a concentration of 13 wt%.

[0042] Preparation of oil-water separation membrane: Using 2300-mesh stainless steel wire mesh as the receiver (cleaned with acetone, ethanol, and deionized water, respectively), the oil-water separation membrane was prepared by electrospinning, marked as CFNM-2300. The voltage was kept at 16 kV during the spinning process; the distance between the tip of the needle and the stainless steel wire mesh was 16 cm. The speed at which the pump drives the spinning solution is set to 0.8mL h -1 ; The temperature is controlled at 25 °C and the humidity is about 40%.

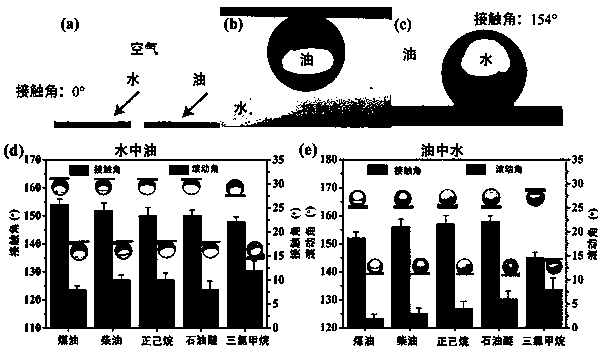

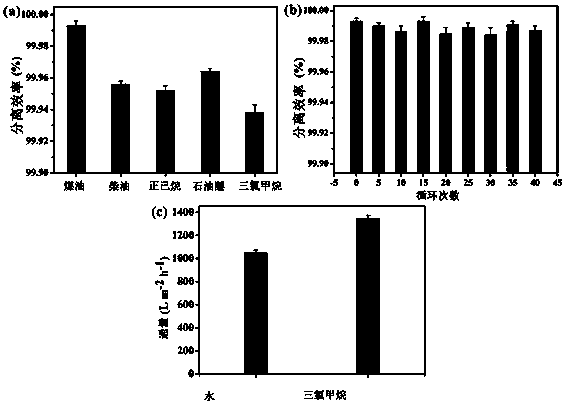

[0043] The oil-water separation application effect of the oil-water separation membrane CFNM-23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com