A manufacturing method of a flexible circuit board

A technology for flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., and can solve problems such as unstable quality, insufficient precision, and difficulty in mass production. , to achieve the effect of stable line quality, improved adhesion, and improved pool effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Please refer to Figure 1 to Figure 7 , Embodiment 1 of the present invention is:

[0032] A method for manufacturing a flexible circuit board, comprising the steps of:

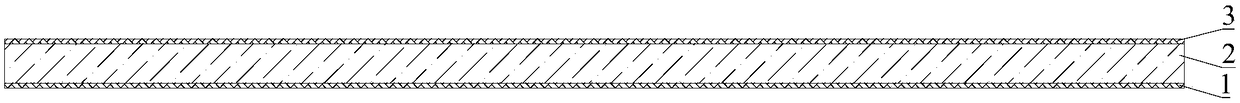

[0033] Such as figure 1 As shown, firstly, the base material is selected, and the base material includes the first bottom copper layer 1, the PI layer 2 and the second bottom copper layer 3 stacked in sequence, and the first bottom copper layer 1 and the second bottom copper layer 3 have a thickness of 2.9-3.1 μm, and the thickness of the PI layer 2 is 24-26 μm. Preferably, the thicknesses of the first bottom copper layer 1 and the second bottom copper layer 3 are both 3 μm, and the PI layer 2 has a thickness of 25 μm.

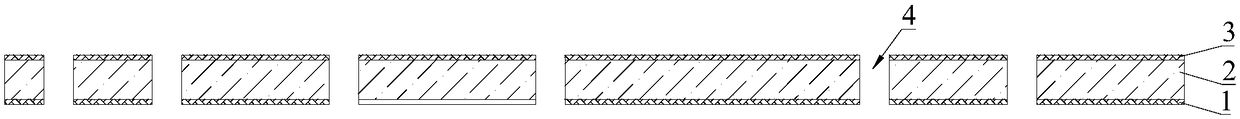

[0034] Such as figure 2 As shown, the base material used for making the flexible circuit board is drilled to form a through hole 4 on the base material. The diameter of the through hole 4 is 0.049-0.051 mm, preferably, the diameter of the through hole 4 is 0.05 mm.

[0035] Such...

Embodiment 2

[0042] Embodiment 2 of the present invention is a method for manufacturing a flexible circuit board, which is different from Embodiment 1 in that:

[0043] Both the thickness of the first bottom copper layer and the second bottom copper layer are 3 μm, the thickness of the PI layer is 25 μm, and the diameter of the through hole is 0.05 mm. During super-roughening treatment, the microetching amount of the second copper layer is 1 μm.

[0044] The thickness of the dry film used when pasting the film is 15 μm, and the pressure of the film is 5.5 kg / cm 2 , the speed is 1.2m / min, and the temperature is 90°C.

[0045] The development point of the development is 45%, the speed is 2.9m / min, and the upper spray pressure is 2.0kg / cm 2 , the spray pressure is 1.8kg / cm 2 .

[0046] The etching speed of vacuum etching is 6m / min, and the upper spray pressure is 2.1kg / cm 2 , the spray pressure is 2.0kg / cm 2 .

Embodiment 3

[0048] Embodiment 3 of the present invention is a method for manufacturing a flexible circuit board, which differs from Embodiment 1 in that:

[0049] Both the thickness of the first bottom copper layer and the second bottom copper layer are 2.9 μm, the thickness of the PI layer is 24 μm, and the diameter of the through hole is 0.049 mm. During super-roughening treatment, the microetching amount of the second copper layer is 0.5 μm.

[0050] The dry film thickness that adopts when described sticking film is 14 μ m, and the pressure of described sticking film is 5.4kg / cm 2 , the speed is 1.1m / min, and the temperature is 85°C.

[0051] The development point of the development is 50%, the speed is 3m / min, and the upper spray pressure is 1.9kg / cm 2 , the spray pressure is 1.7kg / cm 2 .

[0052] The etching speed of vacuum etching is 5.5m / min, and the upper spray pressure is 2kg / cm 2 , the spray pressure is 1.9kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com