Automatic bonding machine for cooker panel components

A panel component and automatic bonding technology, which is applied in the direction of connecting components, manufacturing tools, mechanical equipment, etc., can solve the problems affecting the quality of the finished product of the cooker panel, panel misalignment, troublesome operation, etc., to achieve automatic bonding, improve quality, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

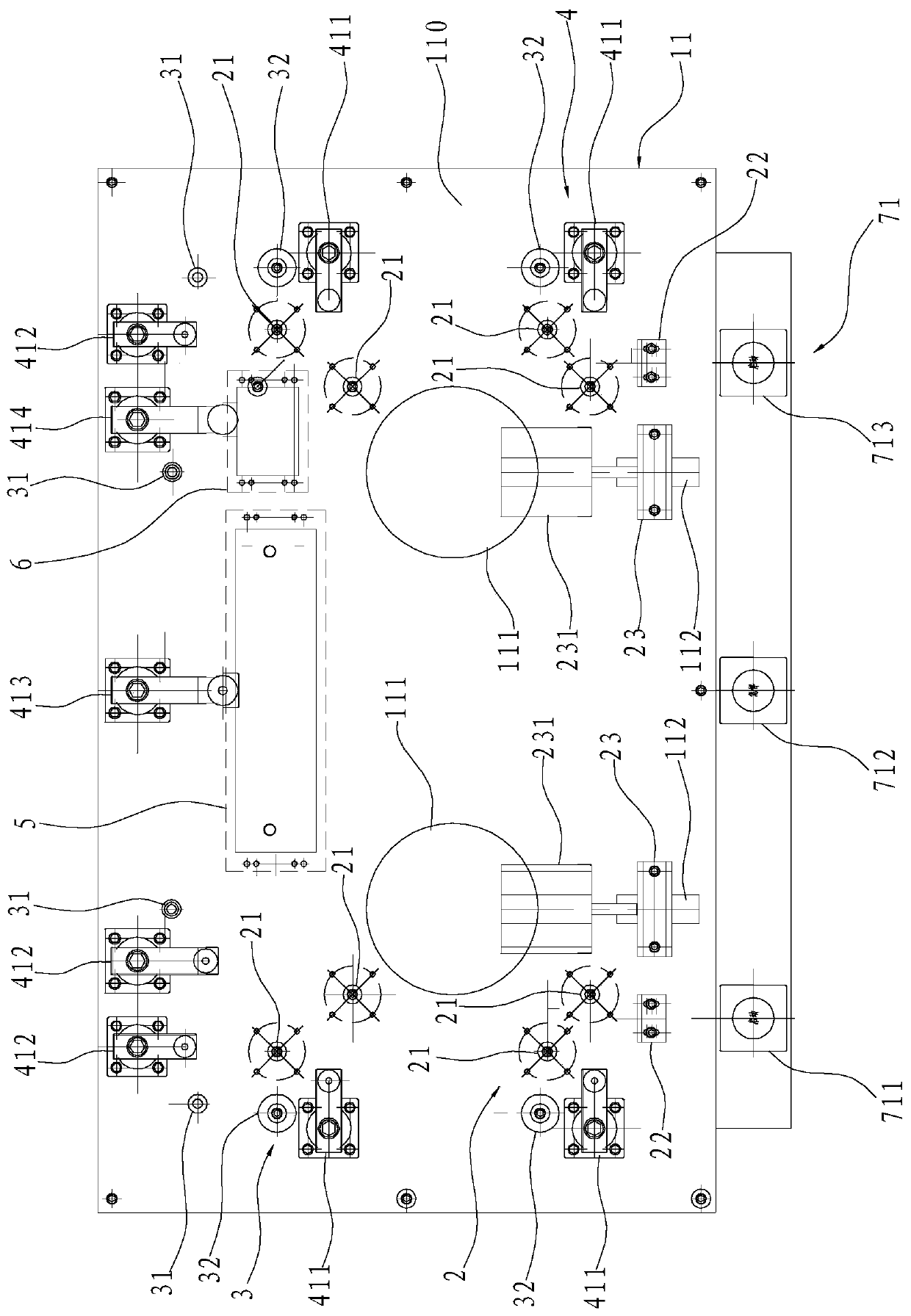

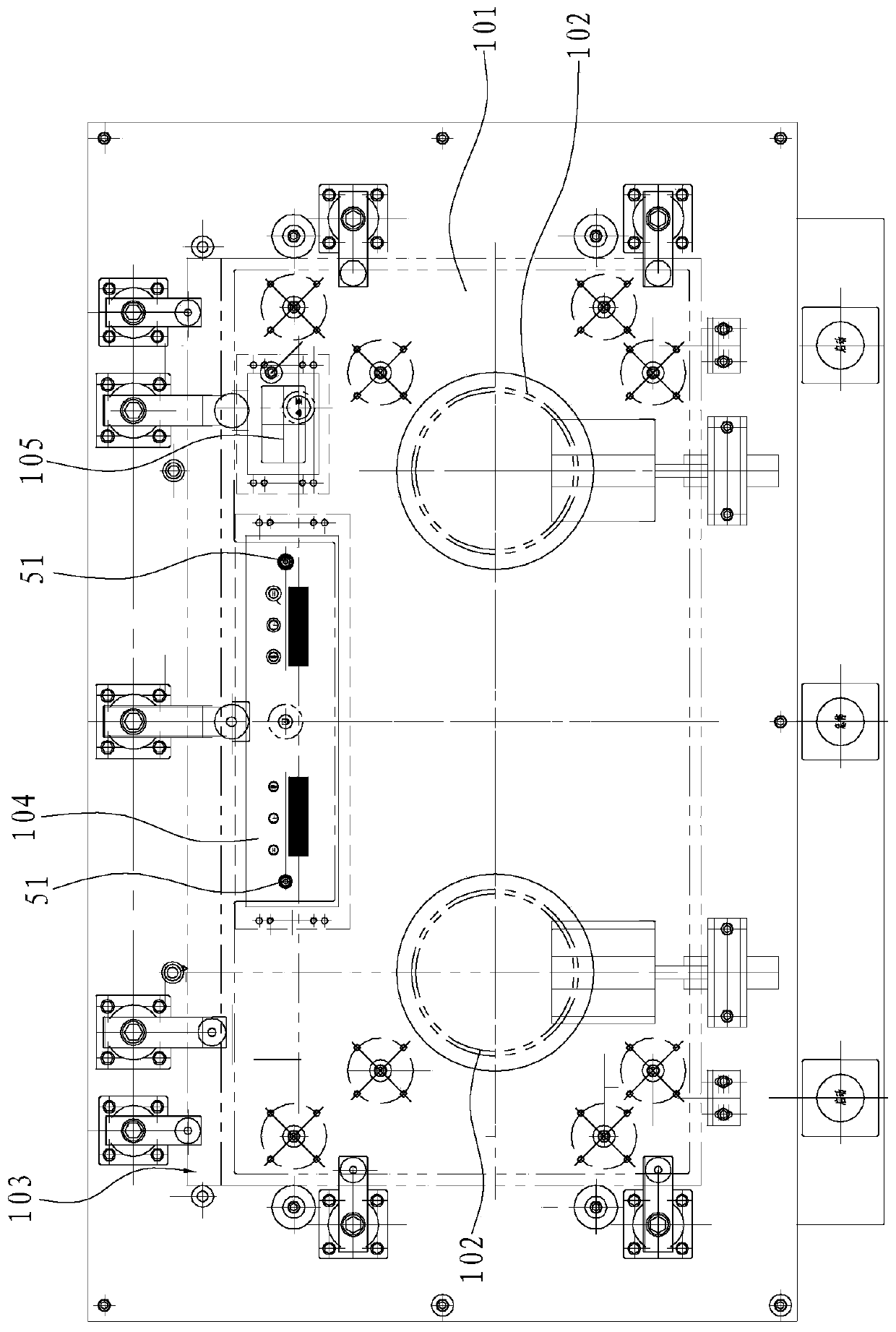

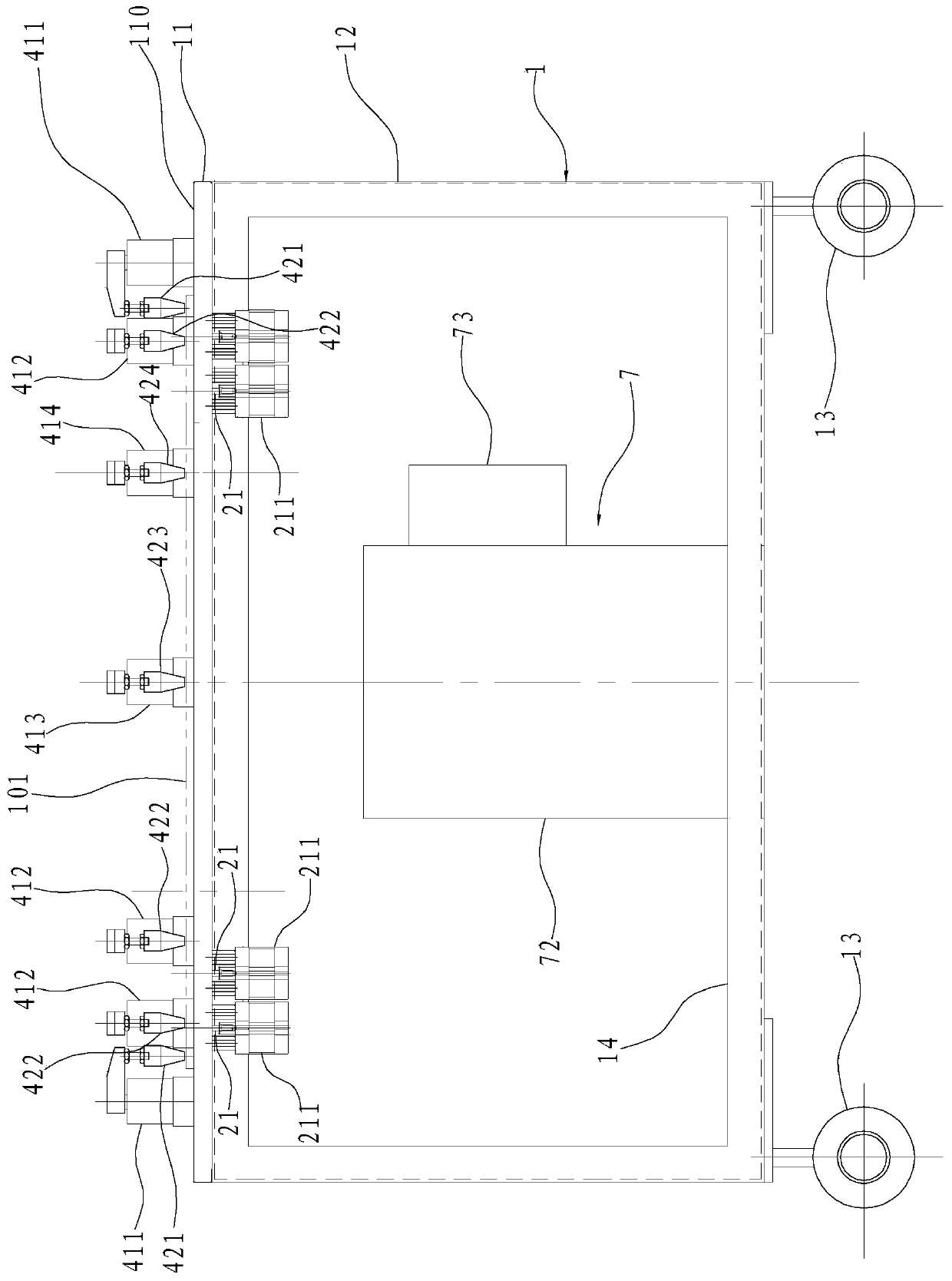

[0021] like Figure 1~5 As shown, an automatic bonding machine for cooker panel components includes a frame 1. The frame 1 includes a workbench 11 and feet 12 respectively arranged at the four corners of the bottom of the workbench 11. The lower ends of each foot 12 are respectively arranged There is a guide wheel 13, and a mounting platform 14 is arranged between the lower ends of the legs 12.

[0022] The above-mentioned workbench 11 has a table 110 for placing workpieces to be processed. In this embodiment, the workpieces to be processed are a cooker panel 101 assembly, and further the cooker panel 101 assembly includes a panel 101 (in this embodiment, the panel 101 is a glass panel ), a metal strip 103 (the metal strip 103 is an aluminum alloy strip in this embodiment), a display board assembly 104 (including a main display board) and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com