Architectural acoustics transforming method for inflatable air film pavilion

An air film pavilion and air film technology, which is applied in building structures, buildings, building components, etc., can solve the problems of large influence of ambient air, high construction cost of metal frames, uncertain corrosiveness, etc., and achieve free adjustment of installation density, The installation method is simple and stable, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, the air dome pavilion of the High School Affiliated to Nanjing Normal University in Nanjing City, Jiangsu Province is selected for acoustic renovation. The air dome pavilion has a length of 80m, a width of 52m, a height of 18.5m, and an area of 4160m 2 , the total internal construction area is about 9650 m 2 , the total internal volume is about 45000m 3 ;The interior of the air dome pavilion is a curved top structure, and the inner covering material does not absorb sound, and the excessive reflection of the sound causes serious acoustic problems such as sound focusing, reverberation time of about 5s, and obvious echoes; at the same time, the air dome There is 1-1.5m wind load sloshing in the membrane pavilion.

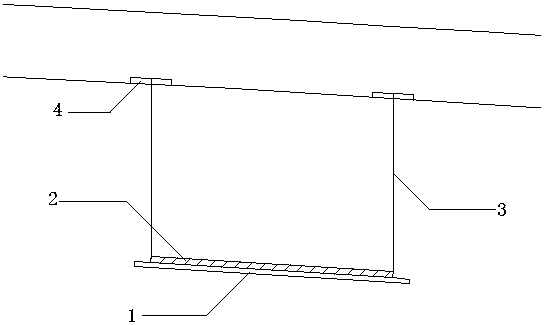

[0030] like figure 1 , for this air dome pavilion, the sound reconstruction method is as follows:

[0031] S1. Prepare soft sound-absorbing body 1 and internal riveted fixing components according to the above air dome pavilion. The material...

Embodiment 2

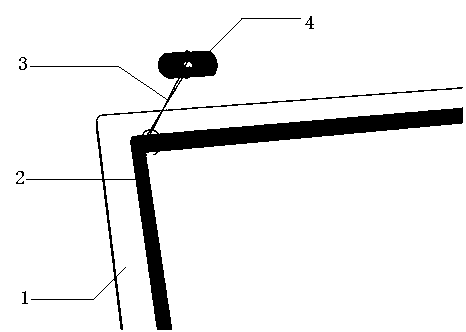

[0037] On the basis of Embodiment 1, this embodiment provides an assembly method of an internal riveted fixing member, such as figure 2 , install the back panel aluminum alloy frame 2 on the back of the soft sound-absorbing body 1 through rivets, and the rivets are distributed at the four corners of the back panel aluminum alloy frame 2 and the middle of the four frames, and at the same time, the aluminum alloy pads There is a mounting hole in the middle of sheet 4; select 4 ring-shaped nylon ropes 3, which are respectively located at the four corners of the aluminum alloy frame 2 of the back panel, and the bottom end passes through the aluminum alloy frame 2 of the back panel and the soft The gap of the sound-absorbing body 1 forms a nylon rope loop at the bottom, and the top end passes through the nylon rope loop at the bottom and passes through the installation hole upwards, then flips down from both ends of the aluminum alloy spacer 4 and wraps around the middle of the alu...

Embodiment 3

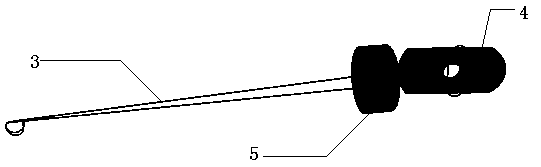

[0039] On the basis of Example 1, this embodiment provides a method for installing the internal riveting fixing member to the interior surface of the dome pavilion, specifically: at the reserved position on the interior surface of the dome pavilion, use sheet-shaped electric heating The air film hole is opened by the soldering iron, the length of the air film hole is 20 mm, the width is 1 mm, and the metal ring 5 is embedded in the air film hole, such as image 3 , the aluminum alloy spacer 4 wrapped with the nylon rope 3 passes through the metal ring 5 and the nylon rope 3 is pulled back to complete the installation. The addition of the metal ring 5 can prevent the soft sound-absorbing body 1 and the aluminum alloy frame 2 of the back panel from being damaged by gravity. Dragging the nylon rope 3 causes the air film hole to expand; the size of the aluminum alloy spacer 4 is selected to be 40mm long and 20mm wide, and the aluminum alloy spacer 4 is inserted into the air film ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com