A cold-formed steel composite constrained cross-shaped energy-dissipating inner core buckling-resistant support member

An anti-buckling bracing, cold-formed steel technology, applied in building components, earthquake resistance, building types, etc., can solve the problems of affecting construction progress, difficult to control processing accuracy, and high requirements for manufacturing accuracy, achieving large flexibility and selection range, preventing Overall instability and friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

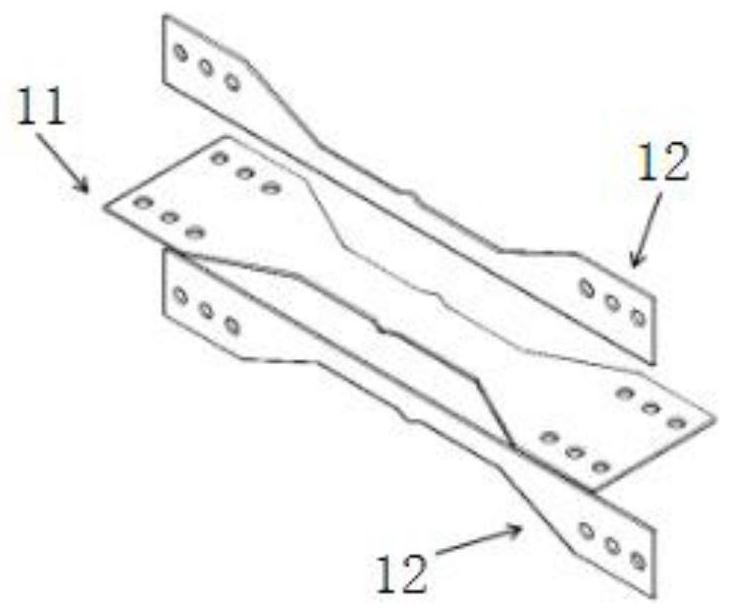

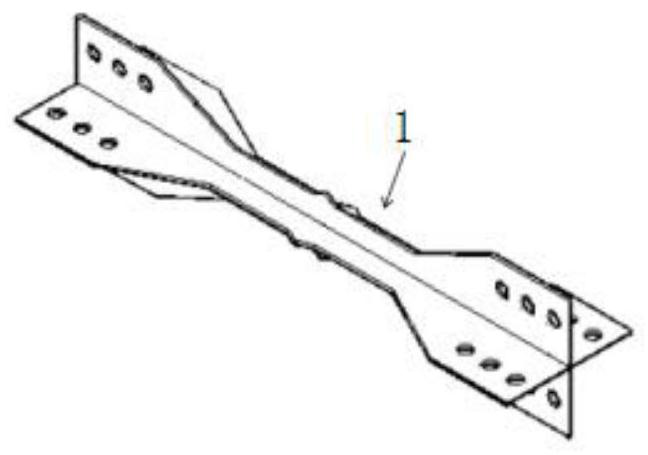

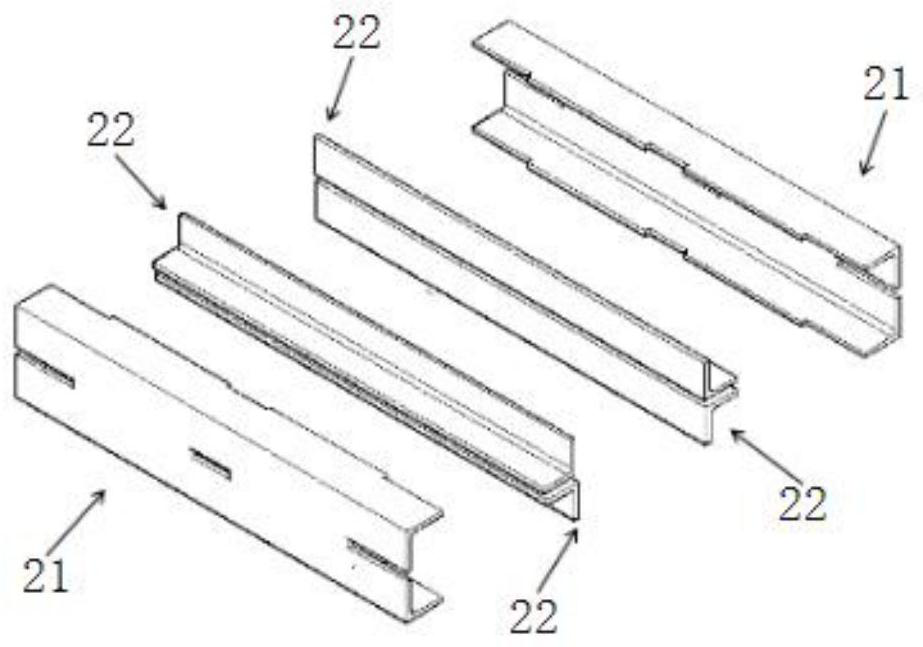

[0039] see Figure 1-8 , a cold-formed steel composite constrained cross-shaped energy-dissipating inner core anti-buckling support member, including a cross-shaped energy-dissipating inner core member 1 and a peripheral cold-formed steel composite restraining member 2, and the cross-shaped energy-dissipating inner core member 1 is located at the outer cold-formed Inside the section steel combination constraining member 2, the cross-shaped energy-dissipating inner core member 1 is formed by welding a total of three variable-section steel plates, one large steel plate 11 and two small steel plates 12, through fillet welds, among which the large steel plate 11 and the small steel plate 12 have the same thickness, and the section width at the end of the large steel plate 11 is the sum of the section width and plate thickness of the two small steel plates 12. 1 Including the yield section, the end connection section and the transition section between them, each steel plate is divi...

Embodiment 2

[0041] see Figure 9-10 , this embodiment is the same as the peripheral cold-formed steel combined constraining member 2 of embodiment 1, the difference lies in the structure of the cross-shaped energy-dissipating inner core member 1, and the cross-shaped energy-dissipating inner core member 1 consists of three first The equal section steel plate 13 and the number of eight first variable section steel plates 14 are formed by welding, the first equal section steel plate 13 is composed of one first equal section large steel plate 131 and two first equal section small steel plates 131. The steel plates 132 are welded, the first equal section large steel plate 131 and the first equal cross section small steel plate 132 have the same section thickness, and the first equal cross section large steel plate 131 has twice the width of the first equal cross section small steel plate 132 and between the plate thickness And, the middle part of the first large steel plate 131 of equal cross...

Embodiment 3

[0043] see Figure 11-12 , this embodiment is the same as the peripheral cold-formed steel combined constraining member 2 of Embodiment 1 and Embodiment 2, the difference lies in the structure of the cross-shaped energy-dissipating inner core member 1, and the cross-shaped energy-dissipating inner core member 1 is composed of the second etc. The section steel plate 15 and the second variable-section steel plate 16 are formed by welding, and the second equal-section steel plate 15 is welded by a second equal-section large steel plate 151 and two second equal-section small steel plates 152. The second variable-section steel plate 16 is welded by a second variable-section large steel plate 161 and two second variable-section small steel plates 162 in quantity. The width is the sum of twice the width of the second variable-section small steel plate 162 and the thickness of the plate, and the width of the second equal-section large steel plate 151 is the sum of twice the width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com