Ultrasonic washing device

A washing device, ultrasonic technology, applied in washing devices, other washing machines, oscillating washing machines, etc., can solve problems such as limited cleaning effect, need for pre-cleaning, and accidents in packaging, so as to improve the overall aesthetics, avoid adverse effects, and avoid stains deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

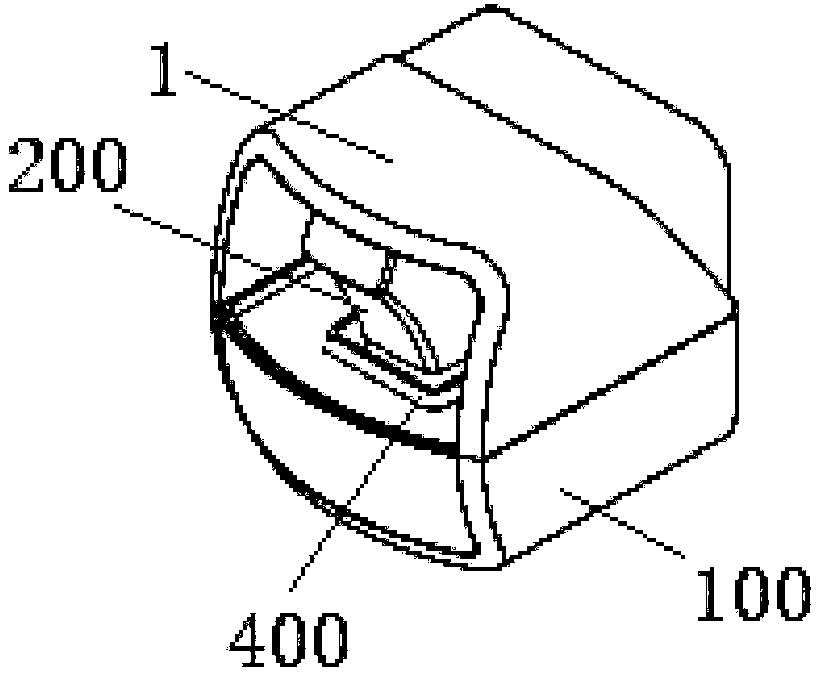

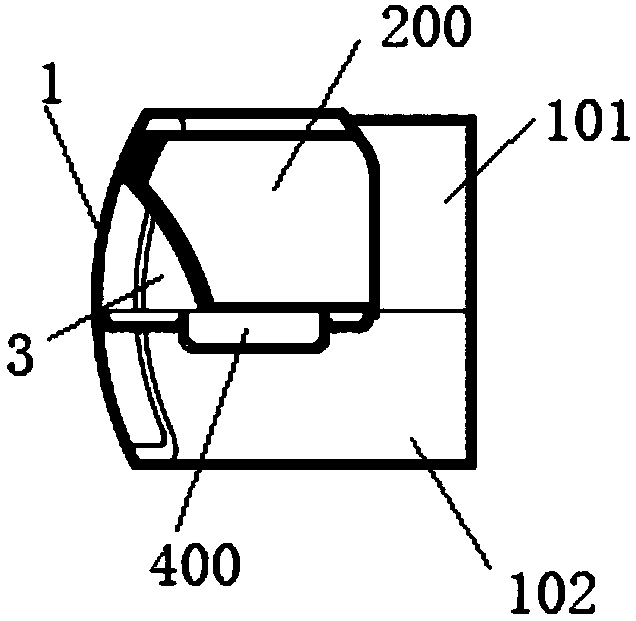

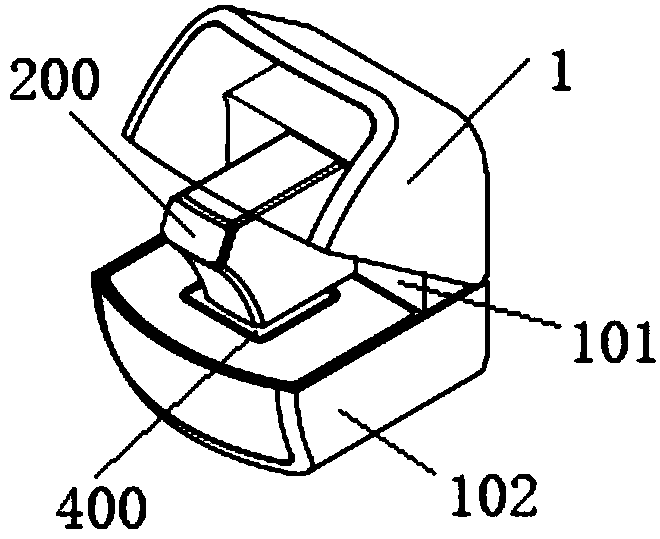

[0049] like Figure 1-11 As shown, this embodiment provides an ultrasonic cleaning device, including a body 100 and a cover 1, the cover 1 is openable / closed and arranged on the body 100, and the body 100 is provided with an ultrasonic generating device 200 and a In the cleaning tank 400 containing the cleaning liquid 5, the ultrasonic generator 200 has an ultrasonic vibration end that generates vibrations, and the ultrasonic vibration end faces the cleaning tank 400; when the cover 1 is closed, the ultrasonic generator 200 and the cleaning tank 400 are covered by the cover. 1, the laundry 4 can be put into the washing tank 400 when the cover 1 is opened.

[0050] The ultrasonic cleaning device of this embodiment can be wall-mounted, fixed on the wall, or a position suitable for installation and use on a fixed plate, and can realize the function of the ultrasonic cleaning device; Taiwan and other positions.

[0051] The ultrasonic cleaning device of this embodiment can clean...

Embodiment 2

[0068] like Figure 1-Figure 7 As shown, this embodiment is a further limitation of Embodiment 1. The cover body 1 of this embodiment is reversibly arranged on the upper part of the body 100, and the cover body 1 is rotatably connected to one side of the body 100, so that the cover body 1 can be turned upside down. Open / drop closed; the downward opening edge of the concave cavity 2 fits and contacts with the outer peripheral edge of the body 100 .

[0069] The cover body 1 of this solution is located on the upper part of the main body 100, and the cover body 1 is opened when it is turned upwards, and is closed and covers the upper part of the main body 100 when it is turned downwards. The cover 1 and the main body 100 can be connected by a rotating shaft, hinged, etc., and the part of the rotating connection is arranged on one side, which is convenient for opening. After the cover 1 is closed, the opening edge of the cavity 2 of the cover 1 matches the size and shape of the o...

Embodiment 3

[0087] This embodiment is another embodiment of the first embodiment. The cover 1 is clamped with the body 100; the body 100 is provided with a circumferential groove, and the edge of the opening of the cavity 2 of the cover 1 Cooperating with the groove, after the cover body 1 is covered on the body 100, the edge of the opening is inserted into the groove and engaged.

[0088] The cover body 1 of this solution has a concave cavity 2 with an opening downward, and the cover body 1 is buckled on the body 100 and covers the upper part of the body 100 . The concave cavity 2 has a top wall, a front wall, a rear wall and two side walls, and the edge of the opening of the concave cavity 2 has downward ribs. The main body 100 includes a horizontal operating platform 102 on which an ultrasonic generating device and a cleaning tank 400 are arranged correspondingly up and down. The outer periphery of the horizontal operating platform 102 is provided with a groove, and the groove is matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com