Environment-friendly neutral rust remover

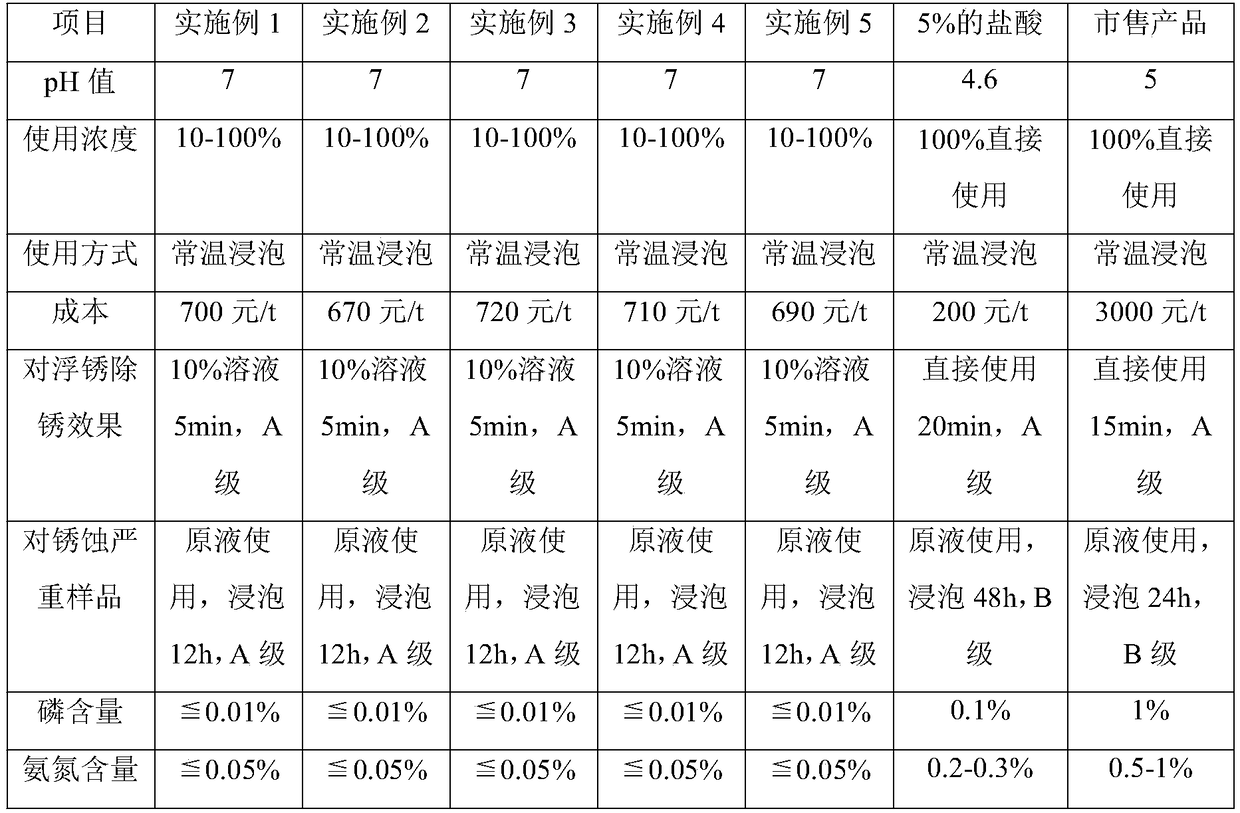

A rust remover and neutral technology, applied in the direction of surface active detergent composition, detergent composition, detergent compounding agent, etc., can solve the problems of cumbersome operation, environmental and personnel health pollution, rust return, etc., and achieve simplification The effect of operating the technological process, reducing pollutant emissions, and changing the principle of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

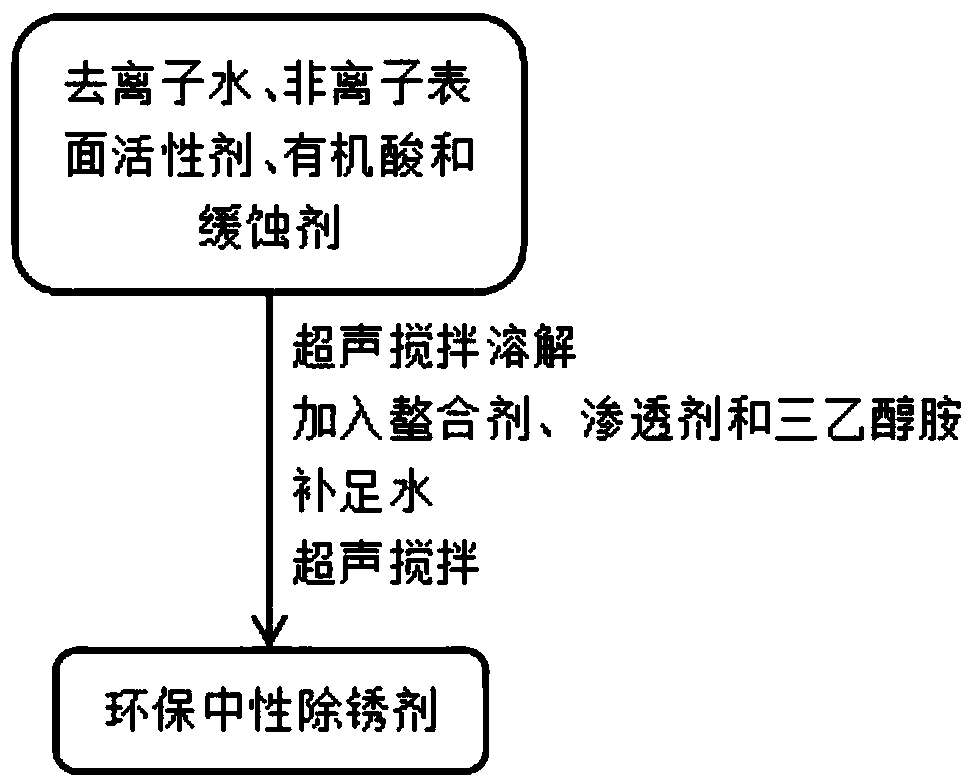

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 environment-friendly neutral rust remover

[0022] Raw material composition:

[0023] 10 parts of benzoic acid, 20 parts of N-hydroxyethylethylamine triacetic acid, 10 parts of mercaptobenzothiazole, 30 parts of alkali-resistant penetrant OEP-7030 parts, 30 parts of triethanolamine, 10 parts of polyoxyethylene alkylphenyl ether, 100 parts of deionized water.

[0024] Preparation:

[0025] Add deionized water, polyoxyethylene alkyl phenyl ether, benzoic acid and mercaptobenzothiazole in sequence to a reactor equipped with a stirring device, stir at 500W ultrasonically for 20 minutes to fully dissolve it, and continue adding N- Hydroxyethylethylamine triacetic acid, alkali-resistant penetrating agent OEP-70 and triethanolamine, after supplementing with water, 500W ultrasonic stirring for 30min, a clear environment-friendly neutral rust remover solution is obtained.

Embodiment 2

[0026] The preparation of embodiment 2 environment-friendly neutral rust remover

[0027] Raw material composition:

[0028] 15 parts of citric acid, 40 parts of nitrilotriacetic acid, 30 parts of dicyclohexyl ammonium nitrite, 60 parts of high temperature penetrant JFC-M, 70 parts of triethanolamine, 20 parts of octylphenol polyoxyethylene ether, deionized water 150 servings.

[0029] Preparation:

[0030] Add deionized water, octylphenol polyoxyethylene ether, citric acid and dicyclohexyl ammonium nitrite sequentially into the reactor equipped with a stirring device, stir 700W ultrasonically for 20 minutes to fully dissolve, and continue to add after the solution is clarified Nitrilotriacetic acid, high temperature penetrating agent JFC-M and triethanolamine, after supplementing with water, 700W ultrasonic stirring for 60min, a clear environment-friendly neutral rust remover solution is obtained.

Embodiment 3

[0031] The preparation of embodiment 3 environment-friendly neutral rust remover

[0032] Raw material composition:

[0033] 12 parts of oxalic acid, 25 parts of sodium hexametaphosphate, 15 parts of stearylamine, 40 parts of rapid penetration agent T, 40 parts of triethanolamine, 12 parts of fatty acid methyl ester ethoxylate, 120 parts of deionized water.

[0034] Preparation:

[0035] Add deionized water, fatty acid methyl ester ethoxylate, oxalic acid and octadecylamine in sequence in a reactor equipped with a stirring device, and stir 600W ultrasonically for 20 minutes to fully dissolve it. After the solution is clarified, continue to add sodium hexametaphosphate, Fast penetrating agent T and triethanolamine, after making up water, 600W ultrasonic stirring for 40min, a clear environment-friendly neutral rust remover solution can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com