Polishing solution for glass and preparation method of polishing solution

A technology of polishing liquid and glass, which is applied in the field of polishing liquid, and can solve the problems of limited popularization and application, increased contact area, and poor guarantee of uniform dispersion and compounding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

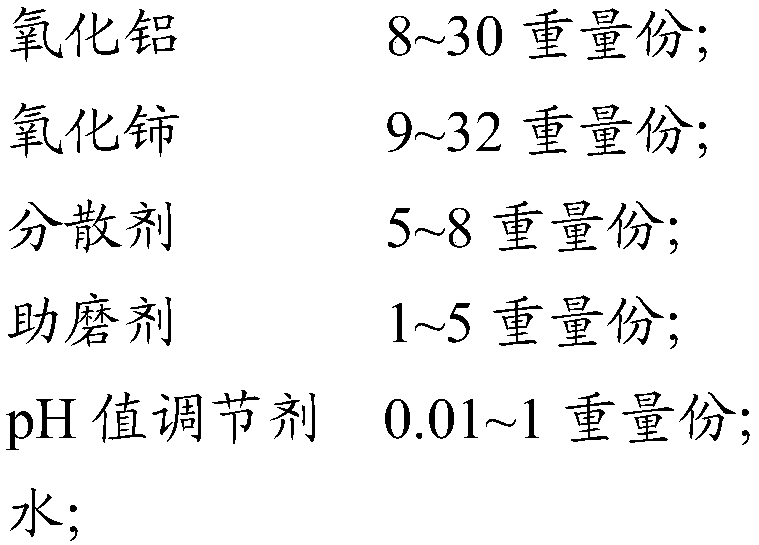

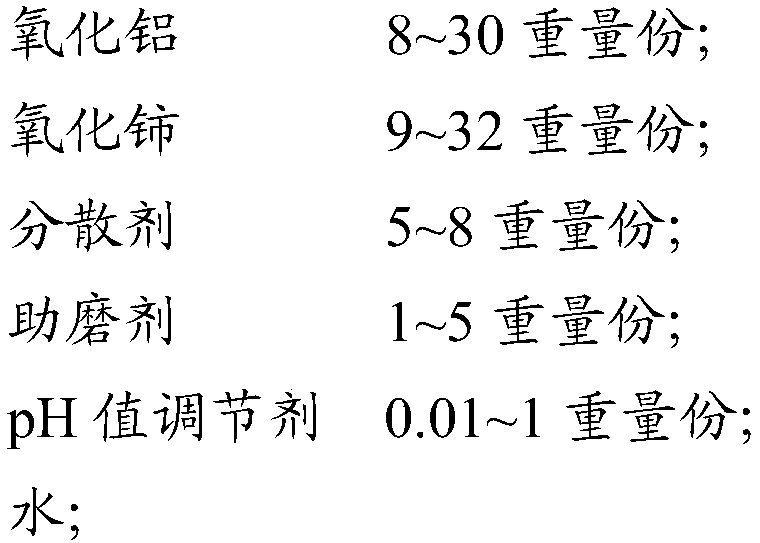

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above polishing liquid for glass, comprising: S1) mixing water, aluminum oxide and cerium oxide to obtain a first mixture; S2) mixing the first mixture, a dispersant and a grinding aid, Obtaining a third mixture; S3) mixing the third mixture with a pH regulator to obtain a glass polishing solution.

[0044] According to the present invention, it is preferred to mix water and surfactant first; the surfactant is the same as described above, so it will not be repeated here; the method of mixing is a method well known to those skilled in the art, and there is no special limitation , In the present invention, it is preferred to mix by stirring; the rotational speed of the stirring is preferably 300-700 rpm.

[0045] After mixing evenly, add aluminum oxide and cerium oxide and mix to obtain the first mixture; the aluminum oxide and cerium oxide are the same as above, and will not be repeated here; the mixing metho...

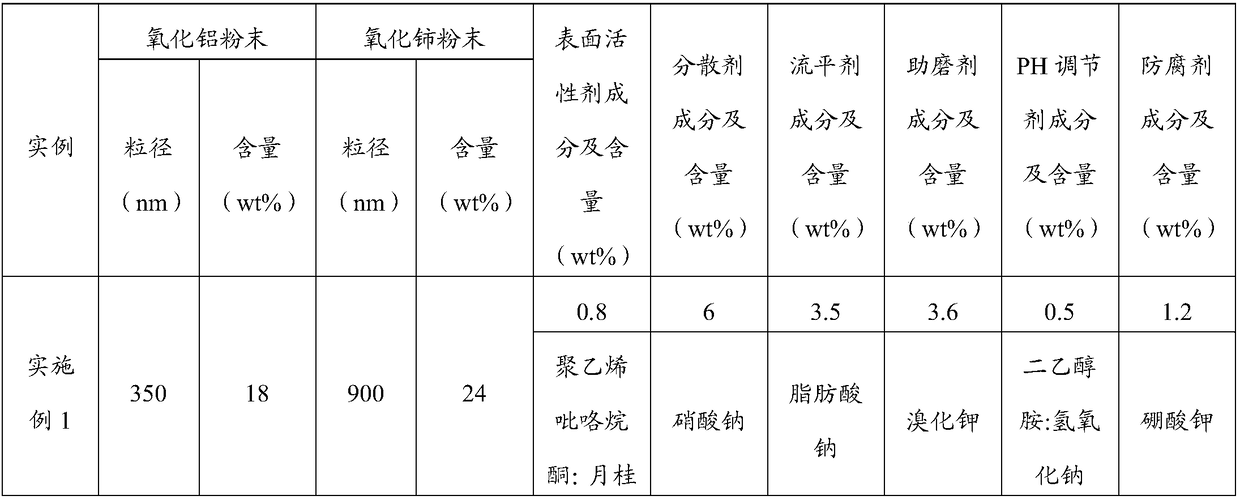

Embodiment 1~5、 comparative example 1~12

[0052] Add each substance according to the amount of raw materials shown in Table 1:

[0053] Preparation Process:

[0054] a) Add deionized water into a container with a certain capacity, add surfactant, and keep stirring at 300-700rpm until uniformly dispersed;

[0055] b) Then slowly add cerium oxide and alumina powder, stop stirring after stirring for 1 hour, and let the solution stand for 5 hours;

[0056] c) Turn on the stirring, add dispersant, leveling agent, preservative and grinding aid respectively, and stir until evenly dispersed;

[0057] d) adding a pH adjuster and stirring until uniformly dispersed to obtain a glass polishing solution.

[0058] Table 1 embodiment 1~5 and comparative example 1~13 raw material consumption

[0059]

[0060]

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com