Preparation method for two-dimensional organic material with adjustable pore diameter

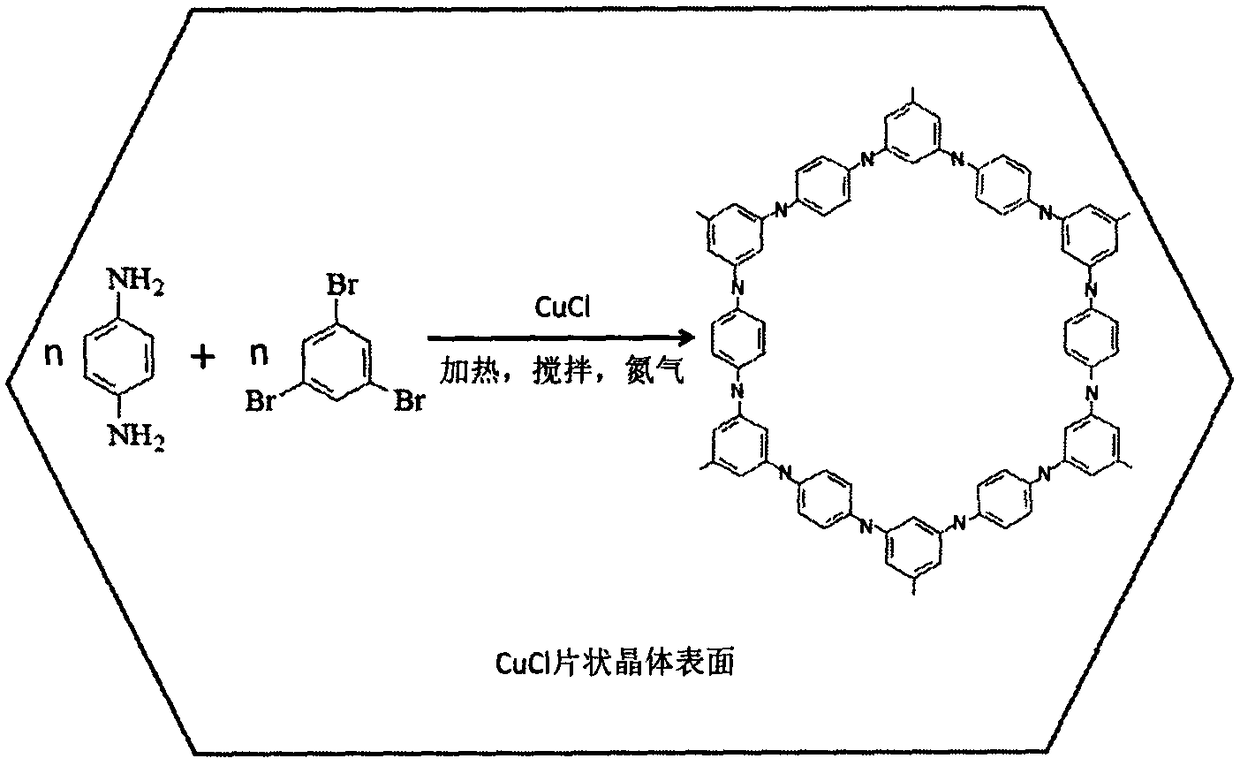

An organic material and pore size technology, which is applied in the field of two-dimensional organic material preparation, can solve problems such as limited reaction types, and achieve the effects of easy industrial batch production, mild reaction conditions, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

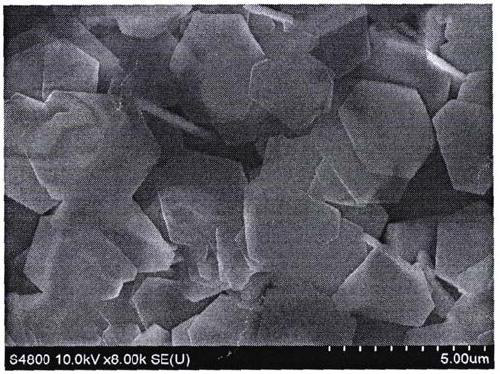

[0027] (1) Choose copper foil with a thickness of 25um. One or both sides of the copper foil are polished planes. Clean the surface of the copper foil with deionized water and dry it at 60°C for later use.

[0028] (2) Add 134.45 mg of copper chloride dihydrate powder into 10 ml of deionized water, stir for 2 minutes, and prepare ~0.1 mol / L copper chloride aqueous solution. Add 1.63 mg of anhydrous ferric chloride powder to the aqueous copper chloride solution.

[0029] (3) Add 10 mL of ~0.1 mol / L copper chloride aqueous solution dropwise to the polished surface of the copper foil, and disperse the liquid evenly on the surface of the copper foil by the wire bar coating method to form a uniform and continuous film.

[0030] (4) Dry the copper foil carrying the copper chloride aqueous solution in an oven at a temperature of 60° C. for 5 minutes.

[0031] (5) Collect the cuprous chloride crystals on the surface of the copper foil by scraping them off with a blade, clean the cupr...

Embodiment 2

[0037] (1) Choose copper foil with a thickness of 25um. One or both sides of the copper foil are polished planes. Clean the surface of the copper foil with deionized water and dry it at 60°C for later use.

[0038] (2) Add 134.45 mg of copper chloride dihydrate powder into 10 ml of deionized water, stir for 2 minutes, and prepare ~0.1 mol / L copper chloride aqueous solution. Add 1.63 mg of anhydrous ferric chloride powder to the aqueous copper chloride solution.

[0039] (3) Add 10 mL of ~0.1 mol / L copper chloride aqueous solution dropwise to the polished surface of the copper foil, and disperse the liquid evenly on the surface of the copper foil by the wire bar coating method to form a uniform and continuous film.

[0040] (4) Dry the copper foil carrying the copper chloride aqueous solution in an oven at a temperature of 60° C. for 5 minutes.

[0041] (5) Collect the cuprous chloride crystals on the surface of the copper foil by scraping them off with a blade, clean the cupr...

Embodiment 3

[0046] (1) Choose copper foil with a thickness of 25um. One or both sides of the copper foil are polished planes. Clean the surface of the copper foil with deionized water and dry it at 60°C for later use.

[0047] (2) Add 134.45 mg of copper chloride dihydrate powder into 10 ml of deionized water, stir for 2 minutes, and prepare ~0.1 mol / L copper chloride aqueous solution. Add 1.63 mg of anhydrous ferric chloride powder to the aqueous copper chloride solution.

[0048] (3) Add 10 mL of ~0.1 mol / L copper chloride aqueous solution dropwise to the polished surface of the copper foil, and disperse the liquid evenly on the surface of the copper foil by the wire bar coating method to form a uniform and continuous film.

[0049] (4) Dry the copper foil carrying the copper chloride aqueous solution in an oven at a temperature of 60° C. for 5 minutes.

[0050] (5) Collect the cuprous chloride crystals on the surface of the copper foil by scraping them off with a blade, clean the cupr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com