A kind of production technology of vidarabine monophosphate

A technology of vidarabine monophosphate and vidarabine monophosphate crude product, which is applied in the direction of preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., and can solve the problems of high toxicity of pyridine and expensive price of solvent acetonitrile, etc. Achieve the effects of easy control, reduced quantity, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

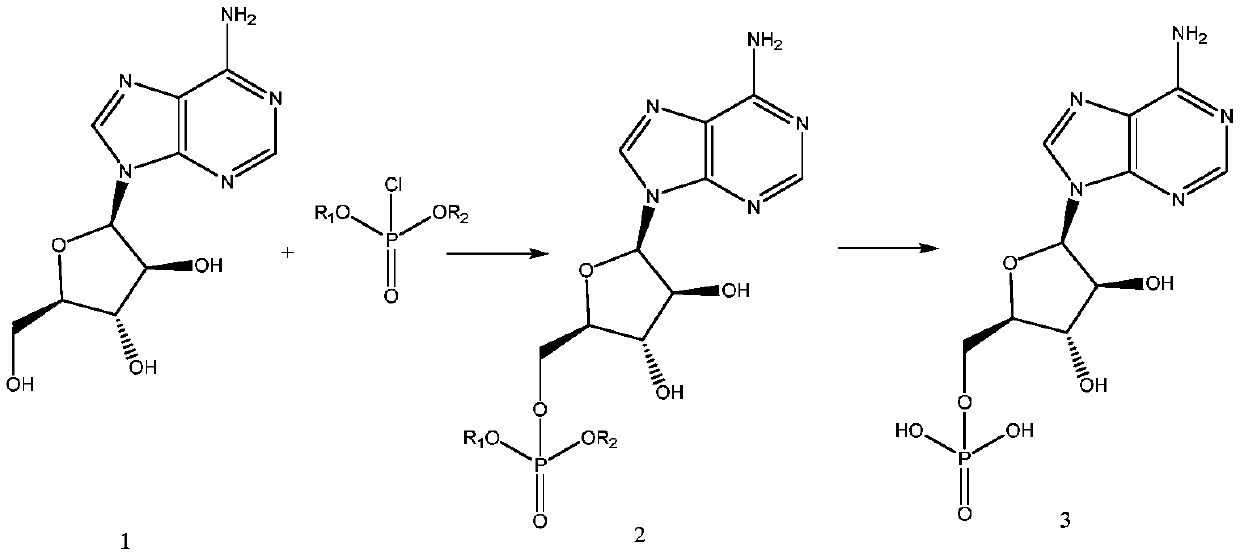

Method used

Image

Examples

Embodiment 1

[0037] A kind of production technique of vidarabine monophosphate, it comprises the steps:

[0038] S1 Mix 30 g of vidarabine in 3 mL of tetrahydrofuran, stir and cool down to 0°C;

[0039] S2 Add 30.83 g of di-n-butylphosphoryl chloride in batches to the cooled system in step S1, and continue the reaction at 10°C after the addition is completed until the remaining amount of adenosine vidarabine does not exceed 3% of the added amount;

[0040] S3 Add 1.5 g of palladium catalyst to the reaction system after the stop of step S2, heat up to 50° C., stir for 8 h, filter, wash the filter cake with ethanol, collect the filtrate, remove the solvent under reduced pressure, and obtain the crude product of adenosine monophosphate ;

[0041] The preparation method of described palladium catalyst comprises the steps:

[0042] Add 17.7g of palladium chloride and 203.3g of magnesium chloride hexahydrate into 20mL of saturated ammonia solution, and stir until completely dissolved; then add...

Embodiment 2

[0047] A kind of production technique of vidarabine monophosphate, it comprises the steps:

[0048] S1 Mix 30 g of vidarabine in 3 mL of acetone, stir and cool down to -5°C;

[0049] S2 Add 52.12 g of bis(4-nitrophenyl)phosphoryl chloride in batches to the cooled system in step S1, and continue the reaction at 5°C until the remaining amount of adenosine vidarabine does not exceed 3% of the added amount stop;

[0050] S3 Add 1.5 g of palladium catalyst to the reaction system after the stop of step S2, heat up to 50° C., stir for 8 h, filter, wash the filter cake with ethanol, collect the filtrate, remove the solvent under reduced pressure, and obtain the crude product of adenosine monophosphate ; The preparation method of the palladium catalyst is the same as in Example 1;

[0051]S4, after dissolving the vidarabine monophosphate crude product obtained in step S3 in water at 40°C, gradually add a mixed solution of ether, methanol, and triethylamine (ether:methanol:triethylami...

Embodiment 3

[0053] A kind of production technique of vidarabine monophosphate, it comprises the steps:

[0054] S1 Mix 30 g of vidarabine with 3 mL of dioxane, stir and cool down to 8°C;

[0055] S2 Add 32.54 g of bis(2-chloroethyl)phosphoryl chloride in batches to the cooled system in step S1, and continue the reaction at 15°C until the remaining amount of adenosine vidarabine does not exceed 1% of the added amount stop;

[0056] S3 Add 1.5 g of palladium catalyst to the reaction system after the stop of step S2, heat up to 50° C., stir for 8 h, filter, wash the filter cake with ethanol, collect the filtrate, remove the solvent under reduced pressure, and obtain the crude product of adenosine monophosphate ;

[0057] The preparation method of described palladium catalyst is with embodiment 1;

[0058] S4, after dissolving the vidarabine monophosphate crude product obtained in step S3 in water at 40°C, gradually add a mixed solution of ether, methanol, and ethyl acetate (the volume rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com