A kind of preparation method of organic-inorganic hybrid perovskite nanowire

A perovskite and nanowire technology, applied in the field of photoelectric functional material synthesis, can solve the problems of low product purity, low preparation efficiency, complicated steps, etc., and achieve the effects of high product purity, low preparation cost, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

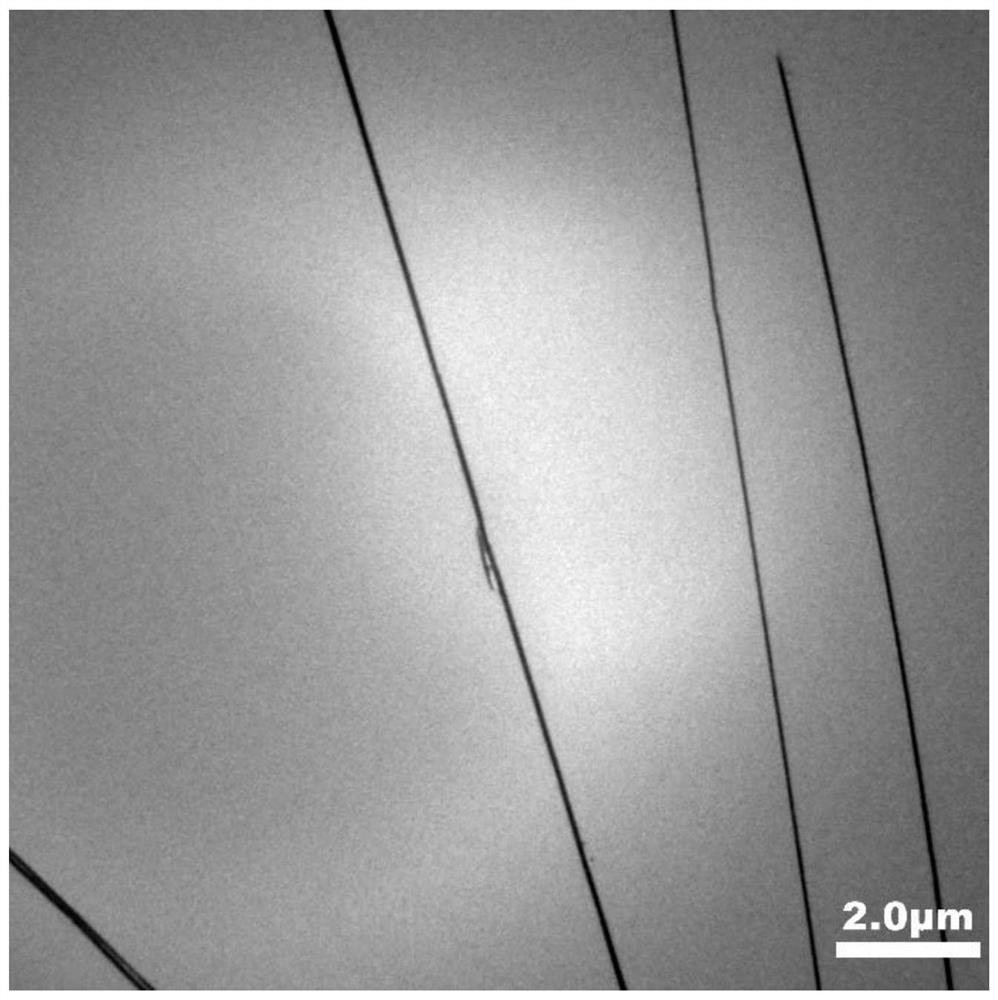

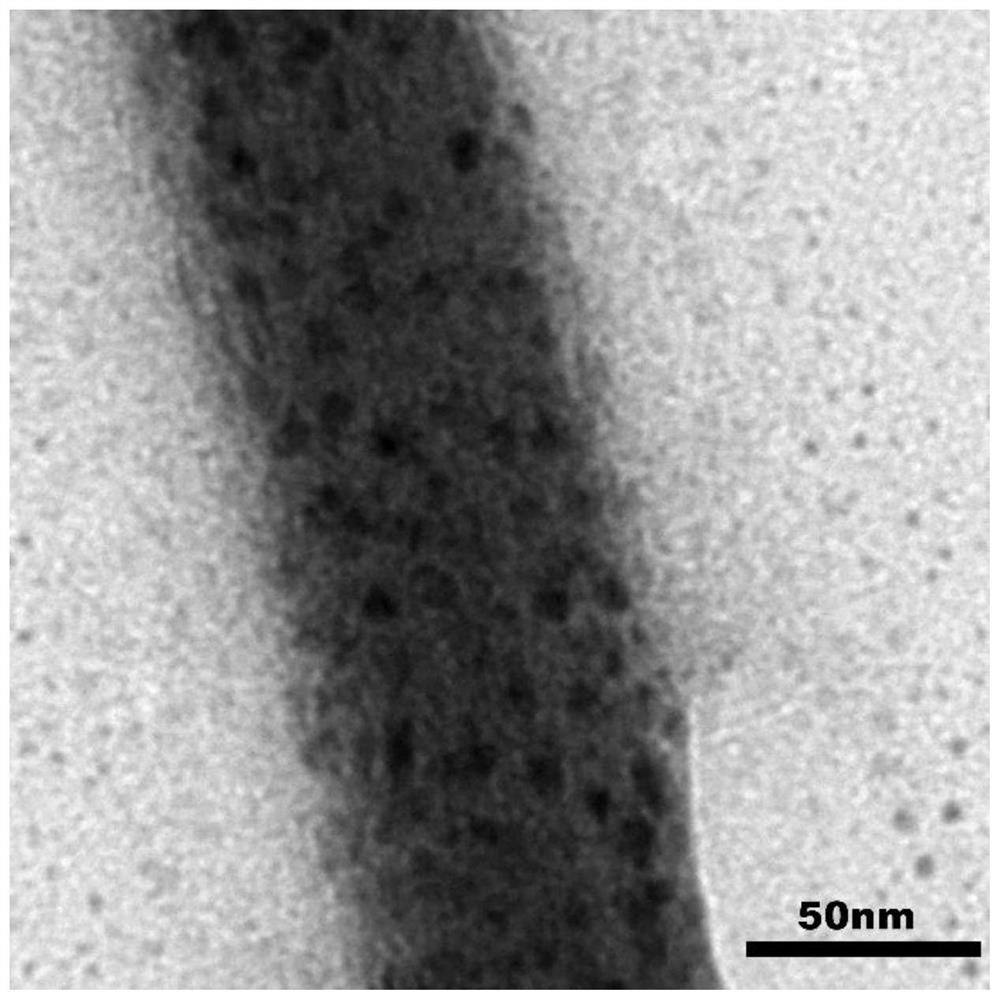

[0021] A method for preparing organic-inorganic hybrid perovskite nanowires, comprising the following steps:

[0022] Step 1: PbI 2 , MAI, PEAI according to PbI 2 :MAI:PEAI = 1:(0.7~1):(0.3~0.5) molar ratio is added dropwise to the benign solvent, and at the reaction temperature of (50~80)℃, keep stirring at the speed of (300~600)rpm (1-3) h, the reaction produces a perovskite precursor solution with a molar concentration of 1 mol / L; wherein, the benign solvent is N,N-dimethylamide;

[0023] Step 2: Add the perovskite precursor solution generated in step 1 dropwise to the stirred poor solvent according to the volume ratio of perovskite precursor solution:poor solvent=(0.2~1):200; wherein, the stirring speed of the poor solvent is ( 500-800) rpm, after the precursor liquid is added dropwise to the poor solvent, the continuous stirring time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com