Organic pigment wastewater treatment technology

A technology for organic pigments and wastewater treatment, which is applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of substandard discharge, high treatment cost, unstable effluent quality, etc., and achieve the cost of wastewater treatment Low temperature, stable effluent quality, and wide range of temperature applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

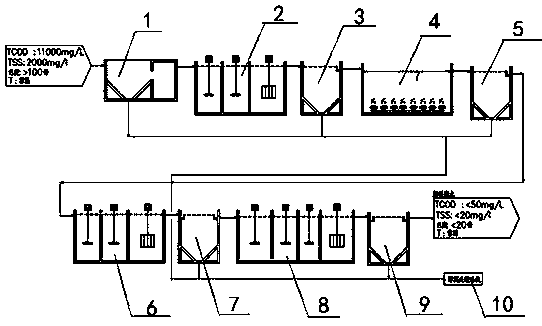

[0021] Combine below figure 1 The embodiments of the present invention are further described in detail.

[0022] The discharge of organic pigment wastewater from an organic pigment production company is 200 cubic meters per hour, the COD of wastewater is 11,000 mg / liter, the TSS is 2000 mg / liter, the chromaticity is greater than 100 times, the water temperature is normal temperature, and the pH of wastewater is 5-6.

[0023] Step 1, the organic pigment wastewater is collected into the grit chamber 1 through the workshop, the sludge at the bottom of the grit chamber 1 is sent to the sludge recovery system 10, and the supernatant flows into the first coagulation reaction system;

[0024] Step 2. The first coagulation reaction system includes the first coagulation reaction tank 2 and the primary sedimentation tank 3. Add coagulant and flocculant to the wastewater in the first coagulation reaction tank 2. The coagulant is chlorinated Iron, polyacrylamide is used as the flocculant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com