High-wear-resistance rubber floor mat and making method thereof

A wear-resistant rubber and floor mat technology, applied in the field of rubber industry, can solve the problems of restricting large-scale popularization and application, poor wear resistance of rubber floor mats, and low strength of rubber particles, etc., and achieves non-decolorization, excellent flame retardancy and aging resistance , good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned high wear-resistant rubber floor mat comprises the following steps:

[0039] 1) Production of the bottom layer: Mix the waste rubber particles and adhesive evenly, pour it into a mold, and shape it under the conditions of a pressure of 7-8MPa and a temperature of 160-180°C to obtain the bottom layer;

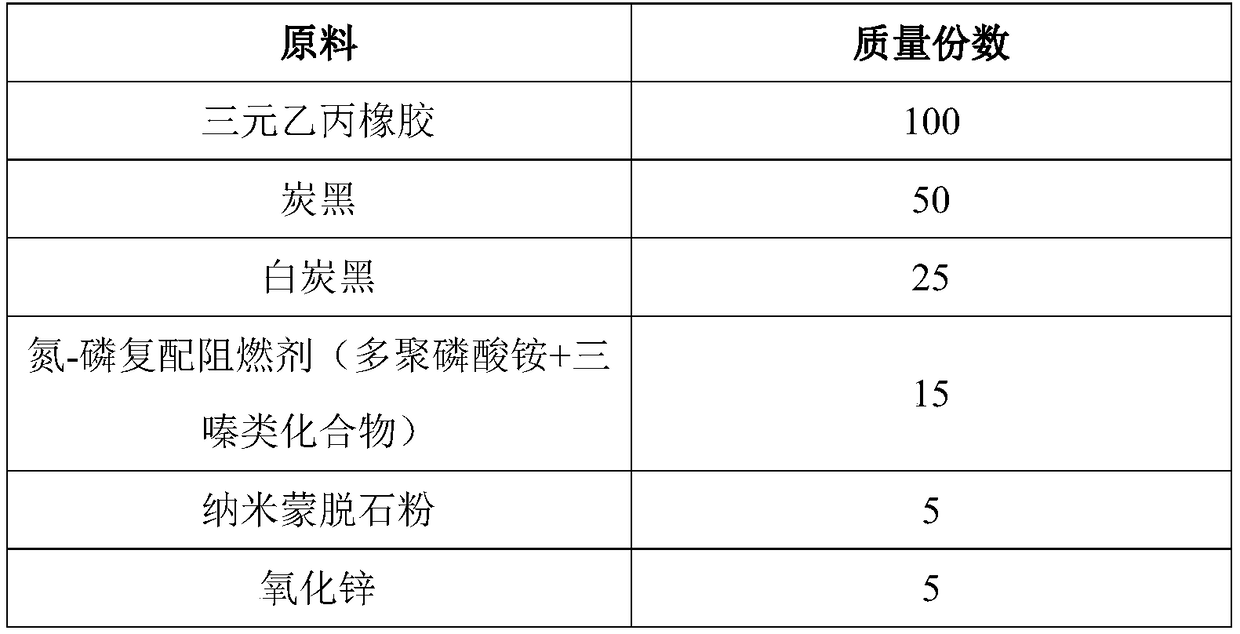

[0040] 2) Production of wear-resistant rubber particles: EPDM rubber, carbon black, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, antioxidant, ultraviolet absorber, anti-mildew Antibacterial agent, accelerator, rubber oil and toner are added to the internal mixer, mixed at 140-160°C, and then kneaded by the open mixer, and the obtained film is cut into rubber strips, and then vulcanized and crushed. Obtain wear-resistant rubber particles;

[0041] 3) Fabrication of the surface layer: Mix wear-resistant rubber particles, reinforcing fibers and adhesive evenly, pour i...

Embodiment 1

[0049] A kind of preparation method of high wear-resistant rubber floor mat is as follows:

[0050] 1) Production of the bottom layer: Mix waste rubber particles (particle size 2-3mm) and adhesive evenly according to the mass ratio of 8:1, pour it into a mold, and shape it under the conditions of a pressure of 7MPa and a temperature of 170°C to obtain a bottom layer (thickness of 5mm);

[0051]2) Production of wear-resistant rubber particles: EPDM rubber, carbon black, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, antioxidant, ultraviolet absorber, anti-mildew Antibacterial agent, accelerator, rubber oil and toner are added to the internal mixer, mixed under the condition of 160 ℃, and then kneaded by the open mixer, the obtained film is cut into rubber strips, and then vulcanized and crushed to obtain the resistant Grinding rubber particles (particle size 1 ~ 2mm);

[0052] 3) Fabrication of the surface layer: Mix...

Embodiment 2

[0059] A kind of preparation method of high wear-resistant rubber floor mat is as follows:

[0060] 1) Production of the bottom layer: mix waste rubber particles (particle size 3-4 mm) and adhesive evenly according to the mass ratio of 8:1, pour it into a mold, and shape it under the conditions of a pressure of 7 MPa and a temperature of 180 ° C to obtain a bottom layer (thickness of 7mm);

[0061] 2) Production of wear-resistant rubber particles: EPDM rubber, carbon black, white carbon black, nitrogen-phosphorus compound flame retardant, nano-montmorillonite powder, zinc oxide, antioxidant, ultraviolet absorber, anti-mildew Antibacterial agent, accelerator, rubber oil and toner are added into the internal mixer, mixed under the condition of 140 ℃, and then kneaded by the open mixer, the obtained film is cut into rubber strips, and then vulcanized and crushed to obtain resistant Grinding rubber particles (particle size 1 ~ 2mm);

[0062] 3) Fabrication of the surface layer: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com