Hot blast welding apparatus

A technology of hot air welding and hot air, which is applied in the field of hot air welding devices, can solve the problems of weak joint force, small pullout force, hydraulic oil leakage, etc., and achieve the effect of sufficient melting and strong pullout force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

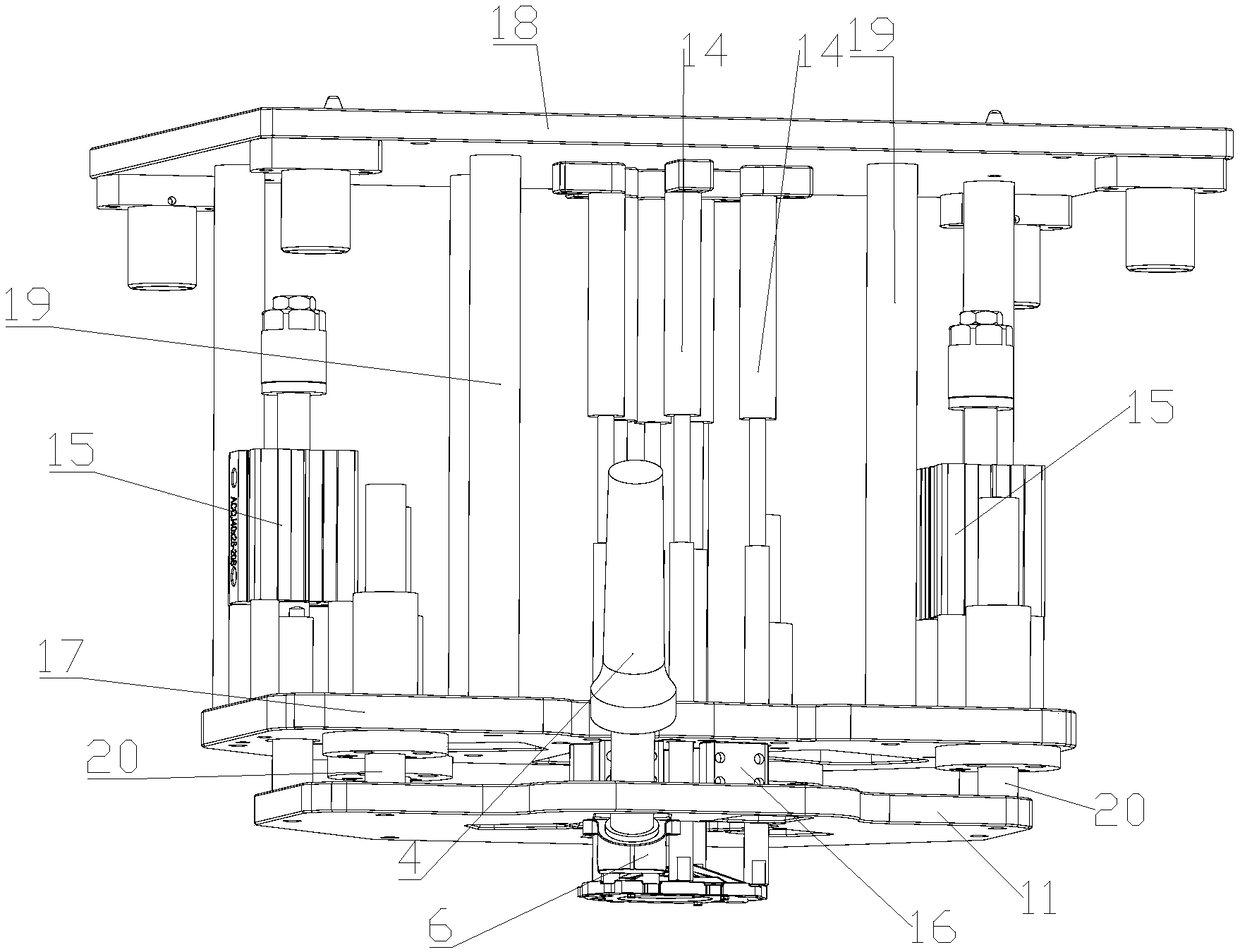

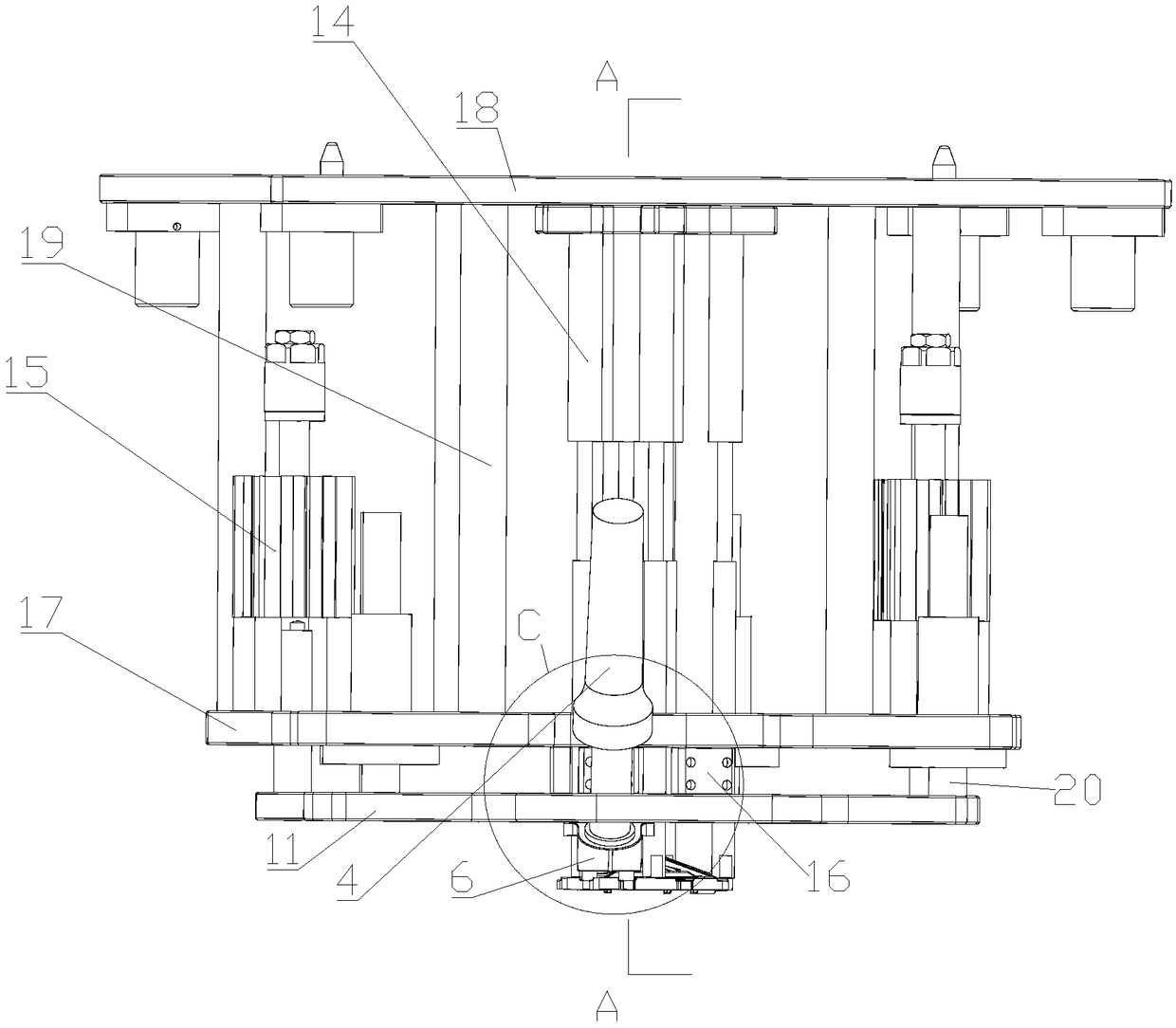

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

[0036] Such as figure 1 As shown, the hot air welding device of this embodiment is used for heat welding the welding point 1 of the parts to be welded, including: a hot air mechanism and a pressing mechanism, wherein the hot air mechanism is used to output hot air to the welding point 1 to soften the welding point 1 or Melted to a deformable degree, the pressing mechanism is set movably, and the melted or softened welding point 1 is deformed during the moving process.

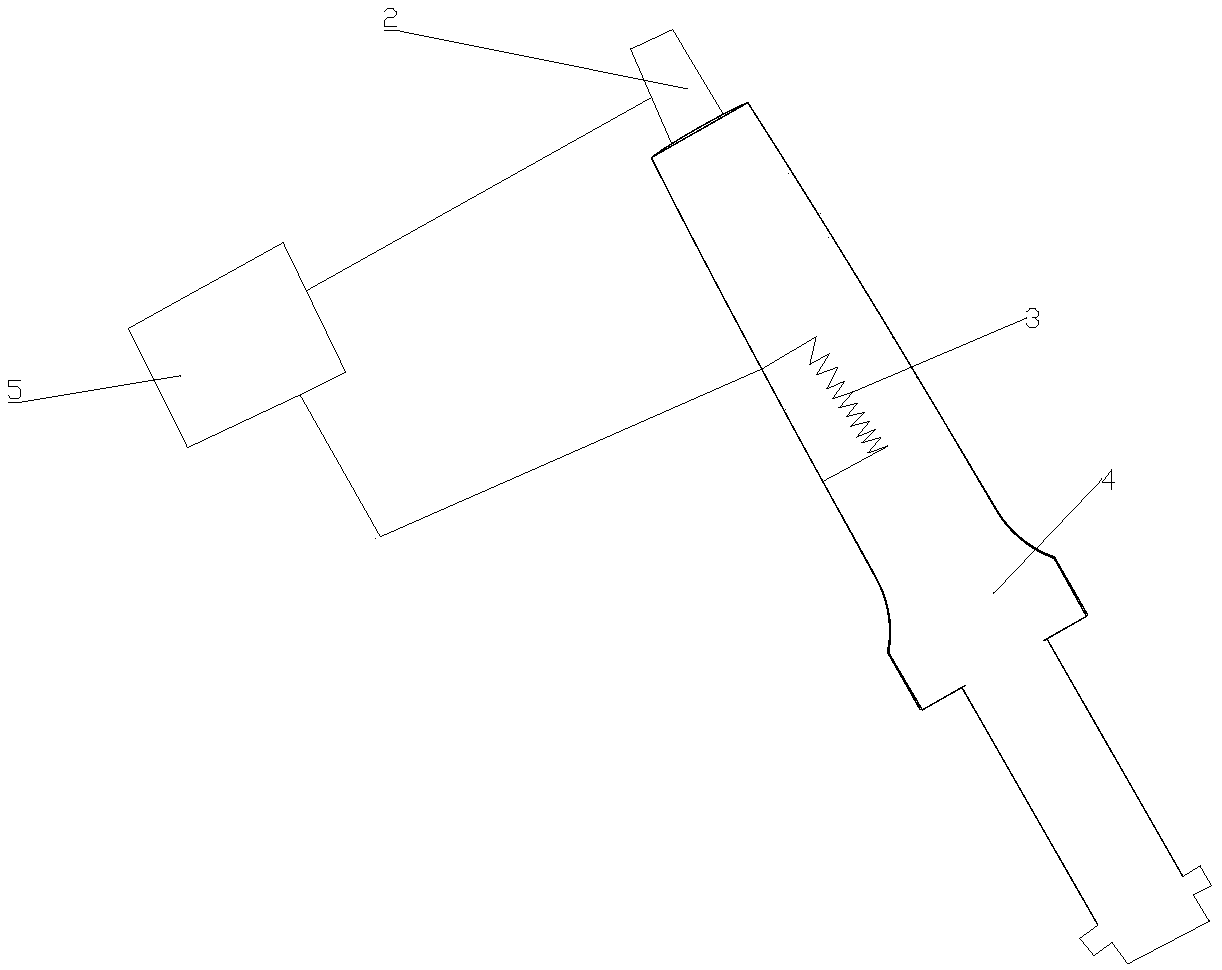

[0037] Such as figure 2 As shown, the hot air mechanism includes: an air source device 2, a heating element 3 and a channel 4, wherein the air source device 2 generates wind and delivers the wind to the channel 4, and the heating element 3 is used for heating the wind passing through the channel 4. heating. The heating element 3 can be arranged inside the channel 4 or outside the channel 4 as long as it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com