An in-situ heat treatment device for electrospray three-dimensional printing

A heat treatment device and 3D printing technology, applied in processing and manufacturing, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of reducing the accuracy of 3D microstructure, affecting printing efficiency, and deviating from the original position, etc., to achieve high-precision 3D micro-nano structure Printing manufacturing, simplifying the 3D printing process, and ensuring the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

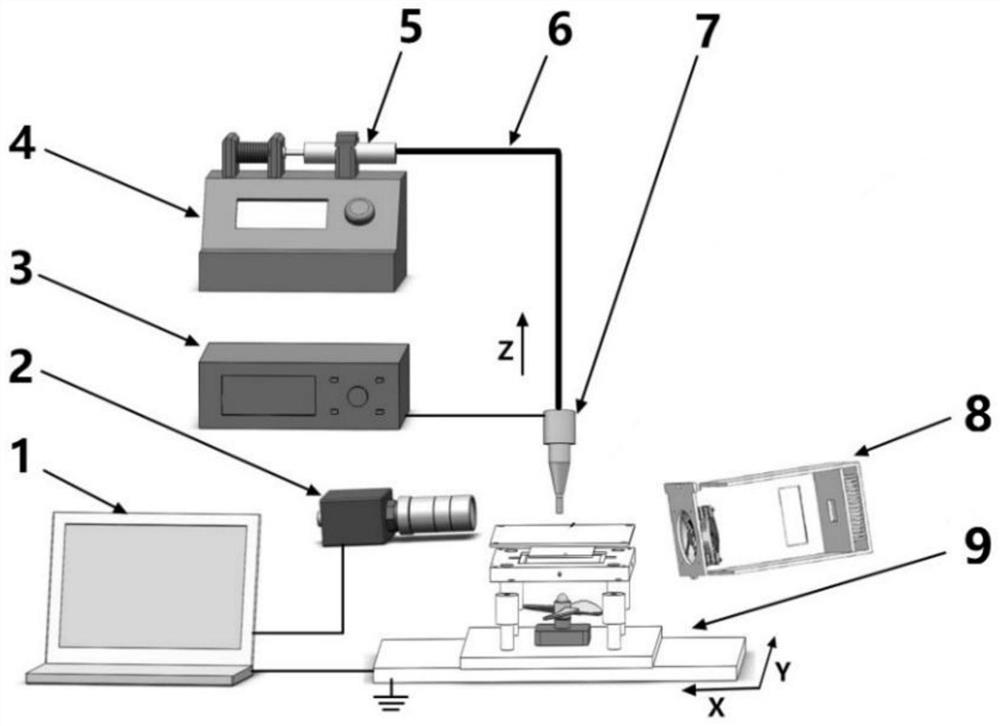

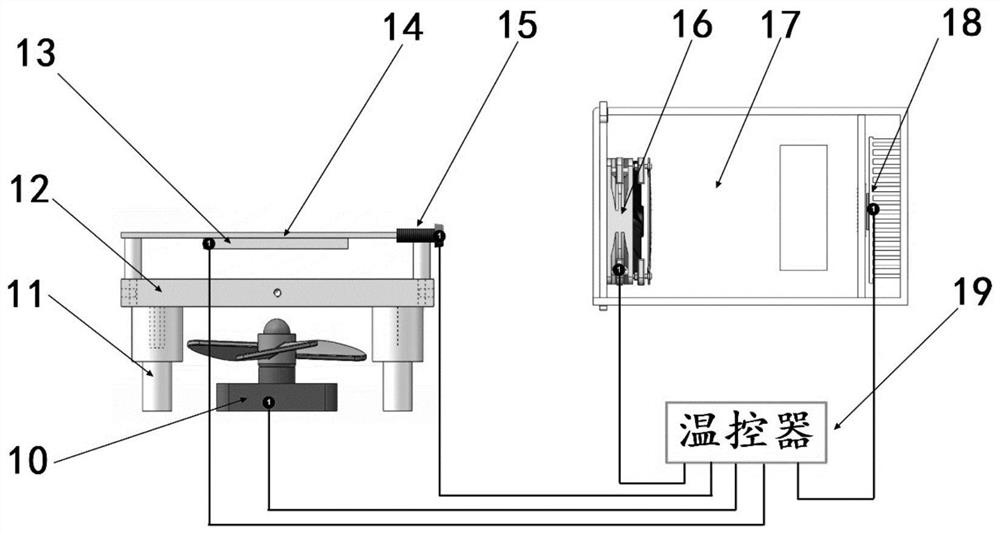

[0017] The present invention will be further described with reference to the technical solution and drawings. The electro-jet 3D printing in-situ heat treatment device of the embodiment includes an electro-jet printing module, an in-situ heating module, an in-situ cooling module, and the like.

[0018] The precision syringe 5 is installed on the micro syringe pump 4 and contains alumina suspension inside. The injection needle 7 has an inner diameter of 300 μm and is connected to a precision syringe 5 through a catheter 6. The micro syringe pump 4 accurately pushes the precision syringe 5 to feed at a flow rate of 20 μL / min. The output voltage of the regulated high-voltage power supply 3 is 1500V, and a stable electric field is formed between the spray needle 7 and the printing plate 14. The printing plate 14 along with the X / Y axis platform realizes movement of various shapes and tracks.

[0019] The printing plate 14 is a square thin metal plate, and the in-situ heating element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com