Decorative plate punching and polishing integrated machine based on stroke energy utilization

An all-in-one machine, energy technology, applied in machine tools, grinders, wood stamping and other directions suitable for grinding the edge of workpieces, can solve the problems of incomplete utilization of energy and high overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

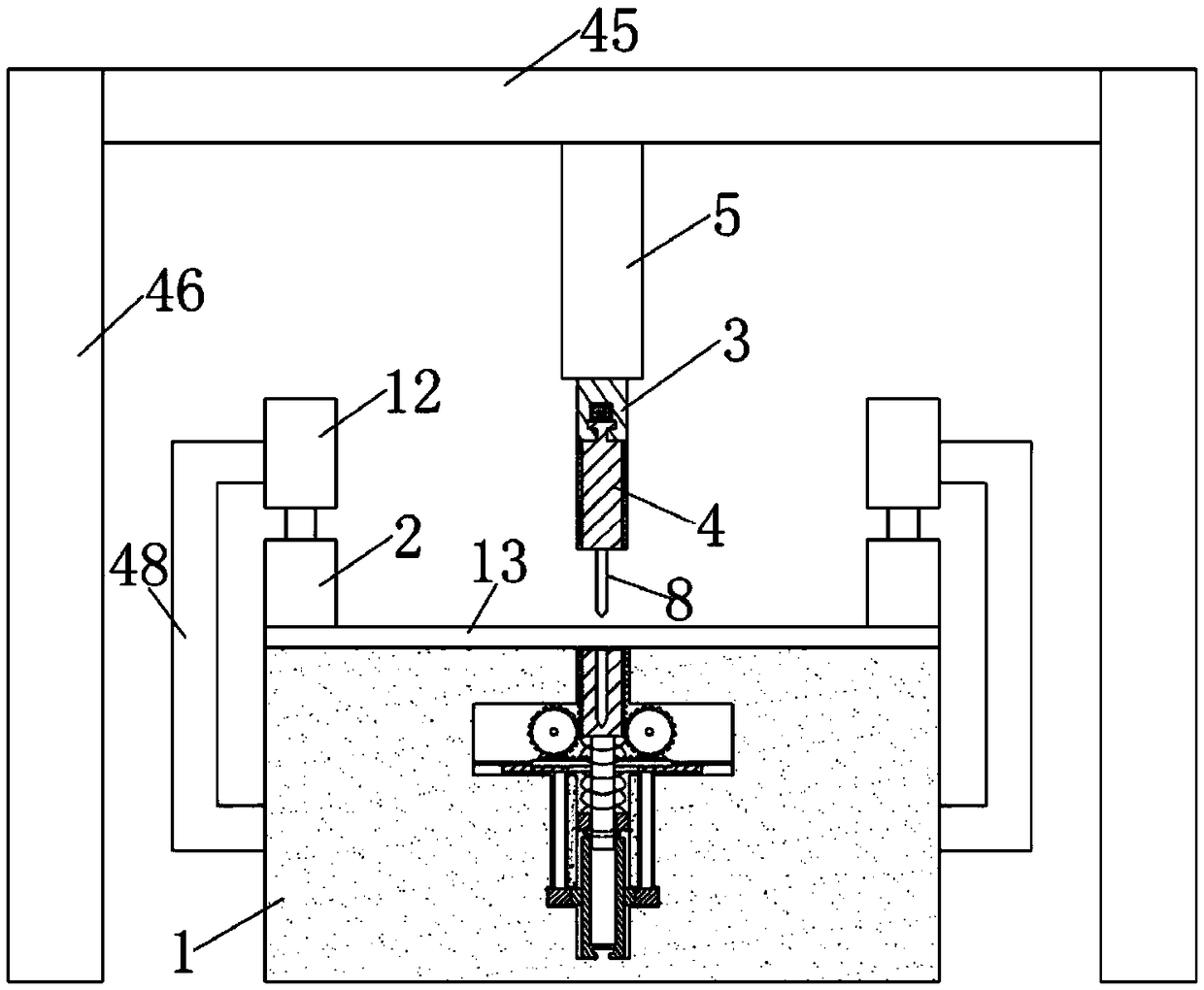

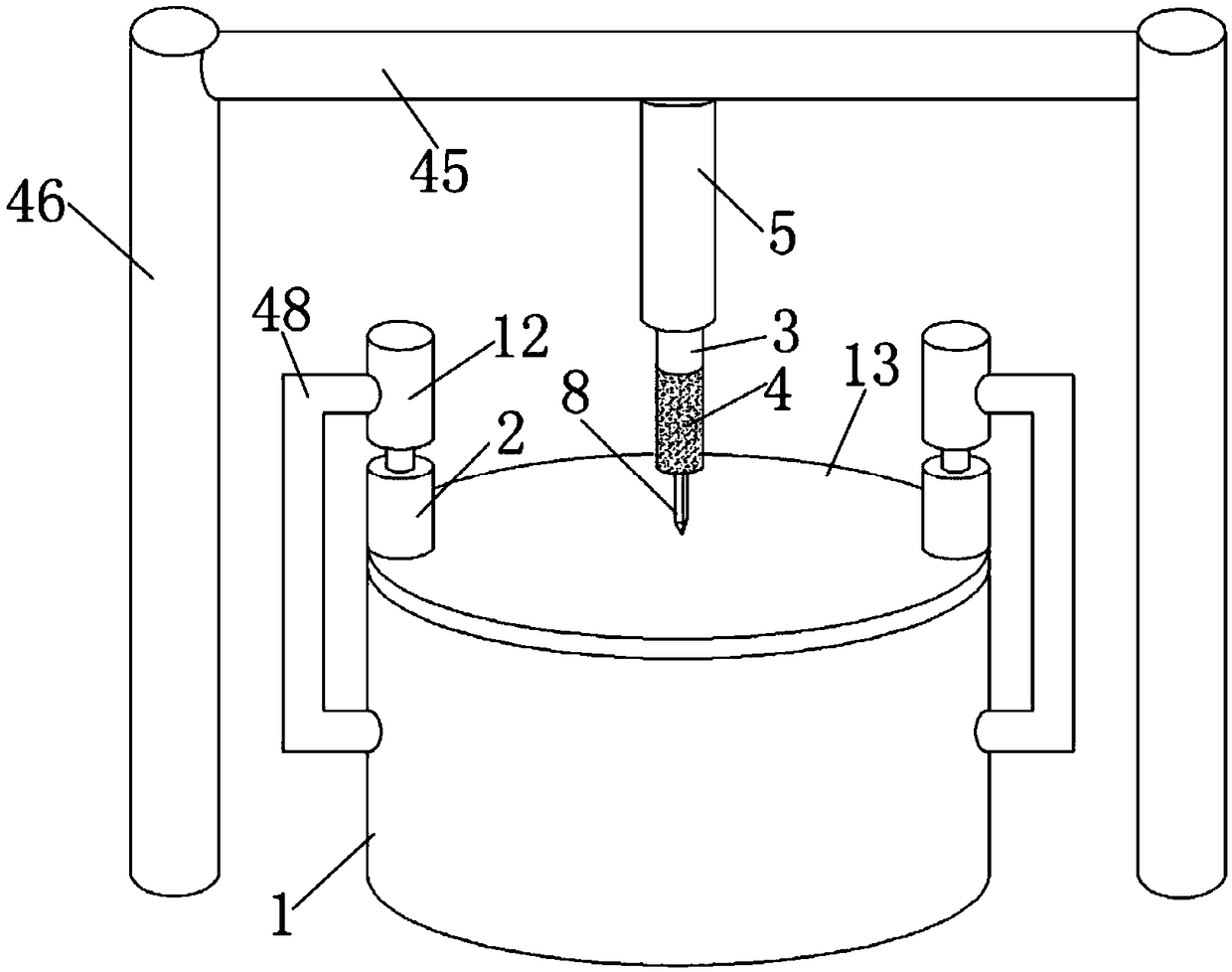

[0019] Taking opening a central hole on a circular decorative plate as an example, the present invention will be further described in conjunction with the following embodiments.

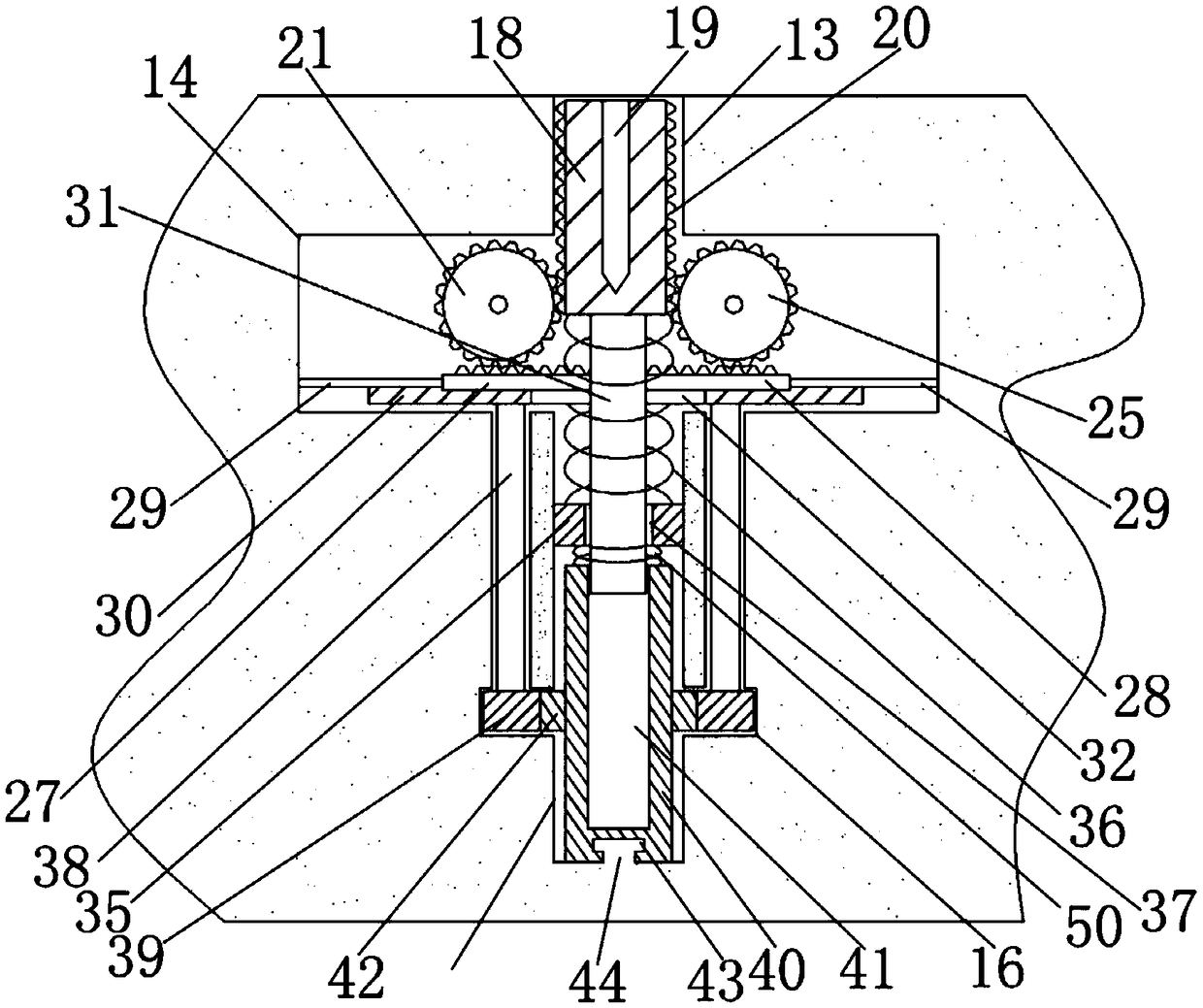

[0020] See eg Figure 1-9 The shown decorative panel punching and polishing machine based on the utilization of stroke energy includes a punch, a base 1 and a locking block 2, the punch includes a fixed part 3 and a rotating part 4, and the fixed part 3 is driven by a hydraulic cylinder 5 to move up and down , the rotating part 4 is located at the lower end of the fixed part 3, the upper end of the rotating part 4 has a first circular plate 6 embedded in the fixed part 3, the first circular plate 6 is fixedly connected with the rotating part 4 through the first connecting rod 7, and the lower end of the rotating part 4 A sprint head 8 is fixedly connected, and a sand surface polishing layer 51 is laid on the outside of the rotating part 4. The sprint head 8 has a cuboid sashimi 9 and a thorn point 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com