Positioning clamp used for titanium alloy ring-shaped casting and clamping method

A technology of ring castings and positioning fixtures, which is applied in the direction of grinding workpiece brackets, etc., can solve the problems of large processing equipment, hard titanium alloy, and inability to grind, so as to achieve centering, reduce operation, and reduce size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

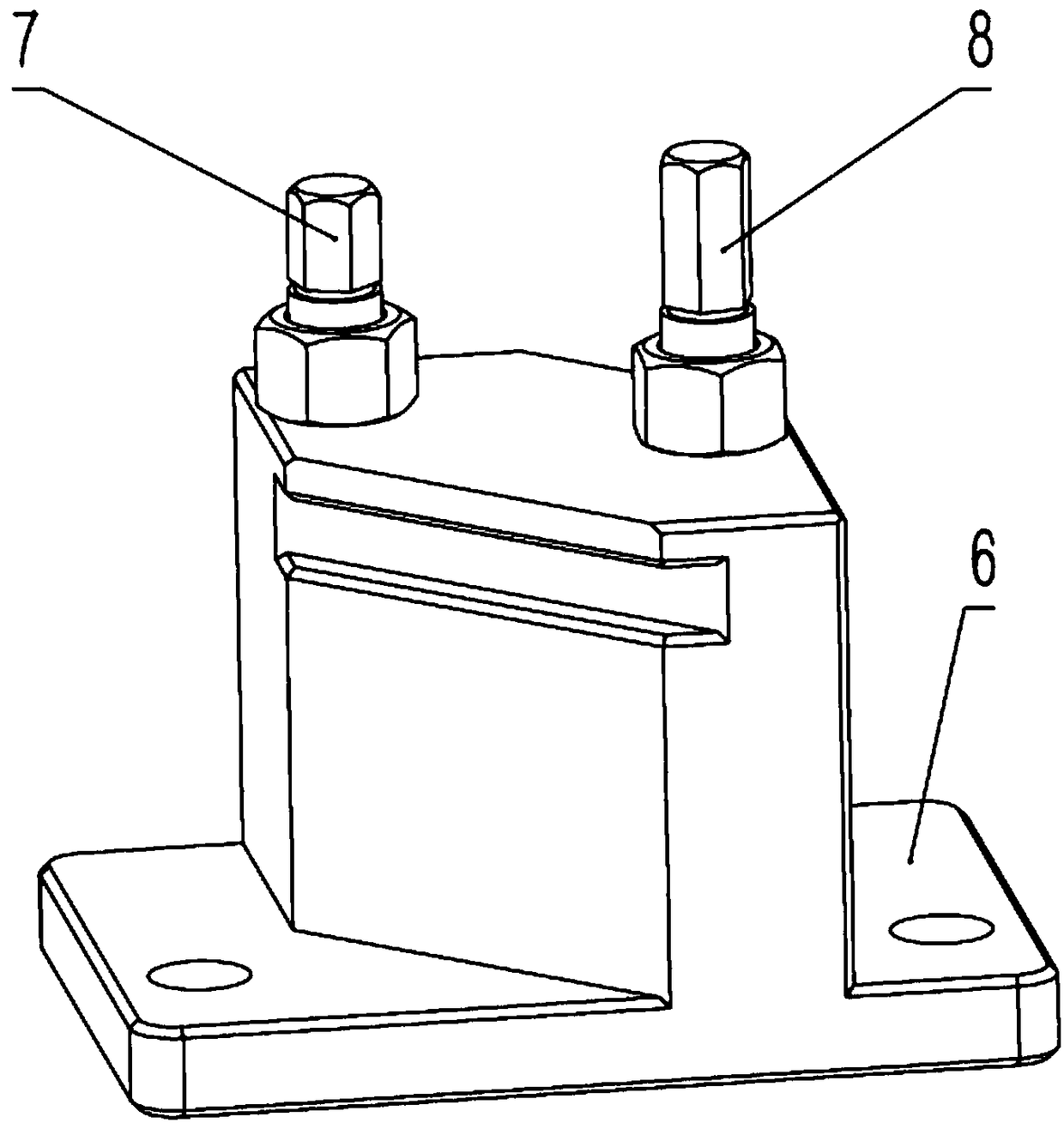

[0029] Among them, 1-rotary table, 2-three-jaw chuck, 3-A floating V-shaped block assembly, 4-pin assembly, 5-three-jaw chuck flange, 6-pin seat, 7-outer pin, 8- Inner pin, 9-upper cover A, 10-lower cover, 11-V block, 12-guide column, 13-flange copper sleeve, 14-spring, 15-limit block, 16-V block seat, 17 flat Key, 18-titanium ring casting, 19-B floating V-block assembly.

[0030] 1. At first introduce the system structure adopted by the present invention.

[0031] Such as Figure 1a The schematic diagram of the front clamping and Figure 1b The schematic diagram of reverse clamping shown mainly includes a rotary table 1, a three-jaw chuck 2 and a three-jaw chuck flange 5, a floating V-shaped block assembly 3 and 19, a pin assembly 4, and a titanium alloy ring casting 18. The three-jaw chu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com