Iron (III) tetracarboxyl phenyl porphyrin implanted metal organic framework preparation and application

A metal-organic framework, phenylporphyrin technology, used in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, special compound water treatment, etc. Problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

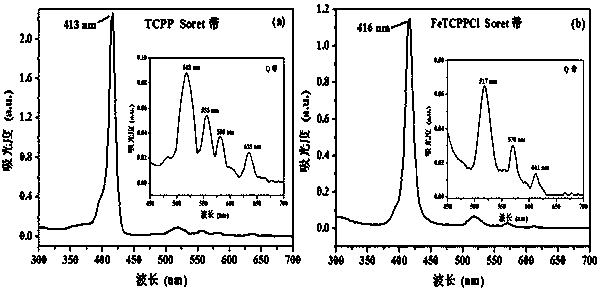

[0047] (1) Preparation of TCPP: Take 6.08 g (40.5 mmol) of 4-formylbenzoic acid and 2.8 g (40.5 mmol) of double-distilled pyrrole, add 120 mL of propionic acid, heat and reflux for 2 to 3 hours; then cool the reaction mixture to room temperature , add 150mL of methanol, while cooling and stirring in an ice bath for 0.5~1 hour; centrifuge to obtain a precipitate, wash with methanol and heated distilled water several times until the filtrate is clear. Finally, dry the obtained purple powder in an oven at 60-80°C for 10-12 hours to obtain 1.587g TCPP.

[0048] (2) Preparation of FeTCPPCl: Take TCPP (0.261 g, 0.33 mmol) and FeCl 2 4H 2 O (0.31 g, 1.82 mmol), was added to 20 mL N,N dimethylformamide, refluxed for 4~5 hours, cooled to room temperature to obtain a dark brown solution, centrifuged, precipitated and washed several times with plenty of water until the filtrate was clear , The solid product was vacuum-dried overnight to obtain a dark brown solid that is FeTCPPCl.

[0...

Embodiment 2

[0052] (1) Preparation of TCPP: Same as Example 1;

[0053] (2) Preparation of FeTCPPCl: same as Example 1;

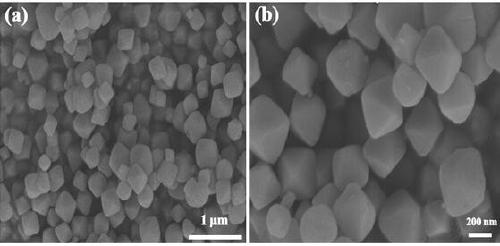

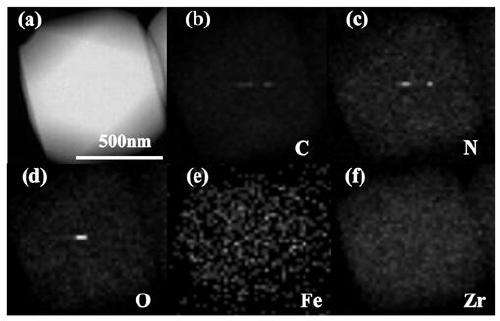

[0054] (3) Preparation of FeTCPPCl-UiO-66 composite material: zirconium tetrachloride ZrCl4 (0.06 g, 0.258 mmol), terephthalic acid BDC (0.06 g, 0.362 mmol), FeTCPPCl (0.0168 g, 0.0185 mmol)) and Benzoic acid (1.0 g, 8.196 mmol) was ultrasonically dissolved in 4 mL of dimethylformamide, treated at 120 °C for 12 hours, cooled to room temperature, centrifuged, and the precipitate was washed several times with dimethyl formamide and acetone, and dried in vacuum , to obtain FeTCPPCl-UiO-66 composite catalyst (the mass percentage of FeTCPPCl is 1.5%);

[0055] (4) Fenton-like and photocatalytic synergistic degradation performance of RhB: RhB can be completely degraded in FeTCPPCl-UiO-66 / visible light / H2O2 system under visible light, and the degradation rate of RhB reaches 89% within 90 minutes.

Embodiment 3

[0057] (1) Preparation of TCPP: Same as Example 1;

[0058] (2) Preparation of FeTCPPCl: same as Example 1;

[0059] (3) Preparation of FeTCPPCl-UiO-66 composite material: zirconium tetrachloride ZrCl4 (0.12g, 0.516mmol), terephthalic acid BDC (0.12g, 0.724mmol), iron (III) tetracarboxyphenyl porphyrin (FeTCPPCl (0.045g, 0.05mmol)) and benzoic acid (2.0 g, 16.392mmol) were ultrasonically dissolved in 8mL dimethylformamide, kept at 120°C for 12 hours, cooled to room temperature, centrifuged, and precipitated with dimethylformamide base formamide and acetone for several times, and vacuum drying to obtain FeTCPPCl-UiO-66 composite catalyst (the mass percentage of FeTCPPCl is 2.0%);

[0060] (4) Fenton-like and photocatalytic synergistic degradation performance of RhB: RhB can be completely degraded in FeTCPPCl-UiO-66 / visible light / H2O2 system under visible light, and the degradation rate of RhB reaches 96% within 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com