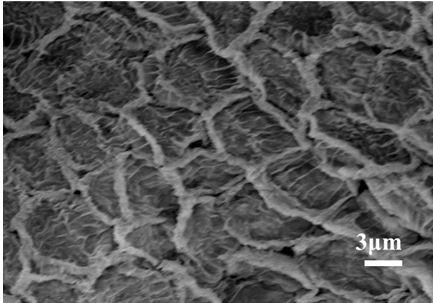

Preparation method of two-dimensional porous Co3O4-ZnO composite nanosheet

A technology of co3o4-zno and nanosheets, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve easy removal, unique two-dimensional porous structure, high catalytic The effect of activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare the template.

[0029] Collect rose petals, wash away the visible stains on the surface of the plant petals, soak them in a mixed solution of ethanol-water, adjust the pH to 3 with hydrochloric acid with a mass fraction of 5%, soak for 4 hours, take them out and wash them with deionized water until Neutral, then place it on a clean bench to dry naturally to form a petal template.

[0030] (2) Dip template.

[0031] Disperse 4 g of the petal template in 400 mL of n-heptane to form a mixed solution of A. Dissolve cobalt nitrate and zinc nitrate in water to form an aqueous solution with a molar ratio of 1:1, referred to as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.5 mol / L. Take 14mL of solution B, add it dropwise into the mixed solution of A under magnetic stirring, and keep stirring and impregnating for 12h.

[0032] (3) Preparation of a two-dimensional porous Co 3 o 4 -ZnO composite nanosheets.

[00...

Embodiment 2

[0037] (1) Prepare the template.

[0038] Collect rose petals, wash away the visible stains on the surface of the plant petals, soak them in a mixed solution of ethanol-water, adjust the pH to 3 with hydrochloric acid with a mass fraction of 5%, soak for 4 hours, take them out and wash them with deionized water until Neutral, then place it on a clean bench to dry naturally to form a petal template.

[0039] (2) Dip template.

[0040] Disperse 3 g of the petal template in 400 mL of cyclohexane to form a mixed solution. Dissolve cobalt chloride and zinc chloride in water to form an aqueous solution with a molar ratio of 1:1, referred to as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.4mol / L. Take 7mL of solution B, add it dropwise to the mixed solution of A under magnetic stirring, and keep stirring and impregnating for 24h.

[0041] (3) Preparation of a two-dimensional porous Co 3 o 4 -ZnO composite nanosheets.

[0042] T...

Embodiment 3

[0045] (1) Prepare the template.

[0046] Collect rose petals, wash away the visible stains on the surface of the plant petals, soak them in a mixed solution of ethanol-water, adjust the pH to 3 with hydrochloric acid with a mass fraction of 5%, soak for 4 hours, take them out and wash them with deionized water until Neutral, then place it on a clean bench to dry naturally to form a petal template.

[0047] (2) Dip template.

[0048] Disperse 2 g of the petal template in 200 mL of n-heptane to form a mixed solution. Dissolve cobalt sulfate and zinc sulfate in water to form an aqueous solution with a molar ratio of 1:1, referred to as solution B; and the total concentration of the metal salt solution in the aqueous solution is 0.2 mol / L. Take 10mL of solution B, add it dropwise into the mixed solution of A under magnetic stirring, and keep stirring and impregnating for 6-48h.

[0049] (3) Preparation of a two-dimensional porous Co 3 o 4 -ZnO composite nanosheets.

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com