Method of modifying magnetic chitosan with ethylenediamine and application of diclofenac in wastewater treatment

A technology of chitosan acetic acid and ethylenediamine, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor chemical stability, achieve simple operation, mild reaction conditions, and avoid secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

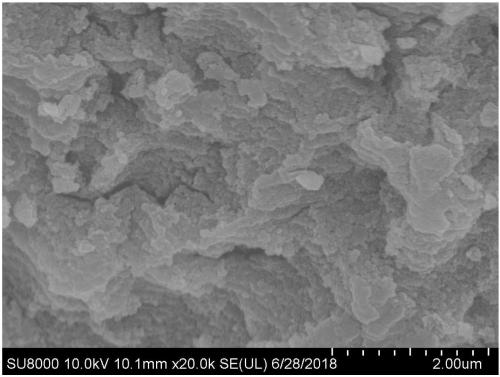

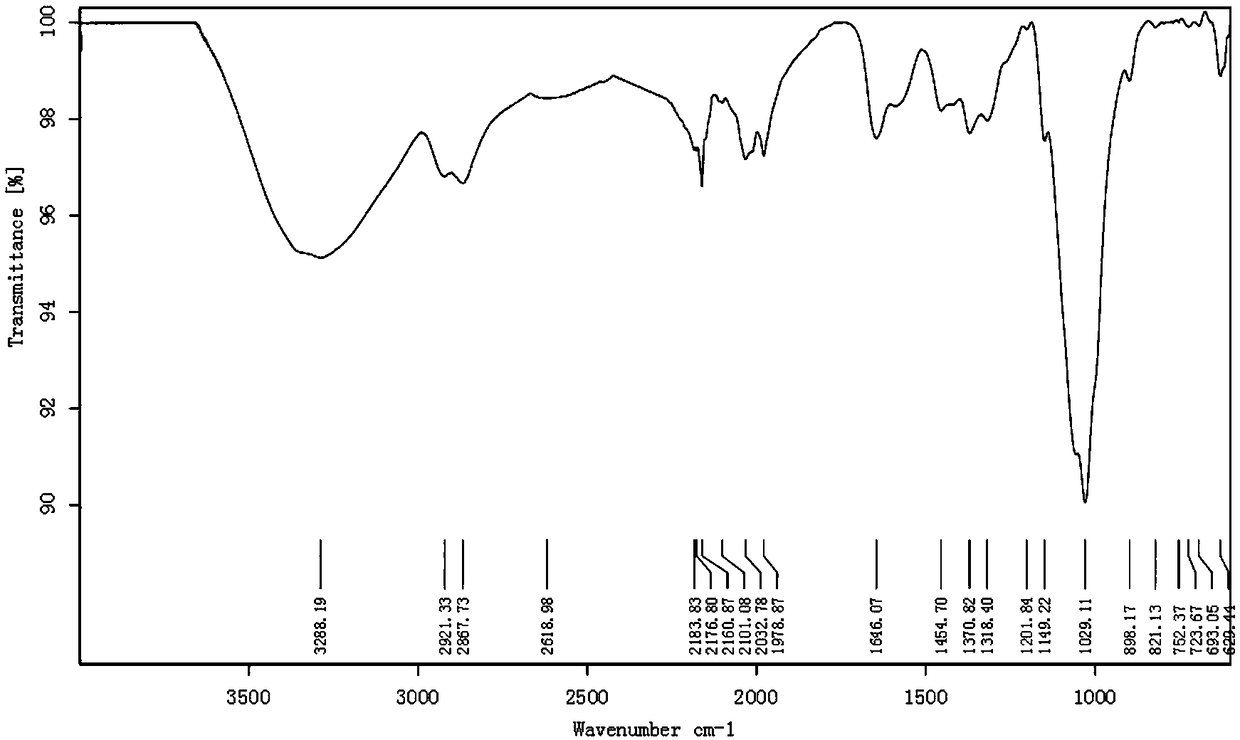

Image

Examples

Embodiment 1

[0032] (1) 1.65g chitosan is dissolved in the acetic acid solution that 75ml volume fraction is 3%, stirs and mixes, makes clear chitosan acetic acid solution A;

[0033] (2) Ferric salt and ferrous salt are added to solution A in step (1) at a molar ratio of 2:1, stirred and mixed evenly to form solution B (concentration of ferric salt is 36.07g / L );

[0034] (3) Use a syringe to slowly and evenly drop solution B into 3mol / L NaOH solution (the volume ratio of the two is 1:3), stir for 1h, and solidify for 2h-3h. Wash the formed magnetic chitosan particles repeatedly with deionized water, and after washing to neutrality, soak the pellets in deionized water for subsequent use;

[0035] (4) Add the pellets in (3) to 500mL of water, add 2.5ml of glutaraldehyde solution, stir evenly, soak for 24 hours, after the reaction, wash the pellets with absolute ethanol and deionized water for later use.

[0036] (5) Put the crosslinked pellets into 400ml of deionized water, adjust the pH...

Embodiment 2

[0038] (1) 1.65g chitosan is dissolved in the acetic acid solution that 75ml volume fraction is 3%, stirs and mixes, makes clear chitosan acetic acid solution A;

[0039] (2) Ferric salt and ferrous salt are added to solution A in step (1) at a molar ratio of 2:1, stirred and mixed evenly to form solution B (concentration of ferric salt is 36.07g / L );

[0040] (3) Use a syringe to slowly and evenly drop solution B into 3mol / L NaOH solution (the volume ratio of the two is 1:3), stir for 1h, and solidify for 2h-3h. Wash the formed magnetic chitosan particles repeatedly with deionized water, and after washing to neutrality, soak the pellets in deionized water for subsequent use;

[0041] (4) Add the pellets in (3) to 500mL of water, add 2.5ml of glutaraldehyde solution, stir evenly, soak for 24 hours, after the reaction, wash the pellets with absolute ethanol and deionized water for later use.

[0042] (5) Put the cross-linked pellets into 400ml of deionized water, adjust the p...

Embodiment 3

[0044] (1) 1.65g chitosan is dissolved in the acetic acid solution that 75ml volume fraction is 3%, stirs and mixes, makes clear chitosan acetic acid solution A;

[0045] (2) Ferric salt and ferrous salt are added to solution A in step (1) at a molar ratio of 2:1, stirred and mixed evenly to form solution B (concentration of ferric salt is 36.07g / L );

[0046] (3) Use a syringe to slowly and evenly drop solution B into 3mol / L NaOH solution (the volume ratio of the two is 1:3), stir for 1h, and solidify for 2h-3h. Wash the formed magnetic chitosan particles repeatedly with deionized water, and after washing to neutrality, soak the pellets in deionized water for subsequent use;

[0047] (4) Add the pellets in (3) to 500mL of water, add 4ml of glutaraldehyde solution, stir evenly, soak for 24 hours, after the reaction, wash the pellets with absolute ethanol and deionized water for later use.

[0048] (5) Put the crosslinked pellets into 400ml of deionized water, adjust the pH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com