Cigarette filter rod with flavoring function, preparation method and application thereof

A cigarette filter rod and functional technology, applied in the field of cigarette production, can solve the problems of cost, safety, environmental protection, efficiency, and taste, which are difficult to be popularized and applied, difficult to achieve the expected effect, single form of cigarette filter rod, etc., and achieve safety More security, low cost, and outstanding flavoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

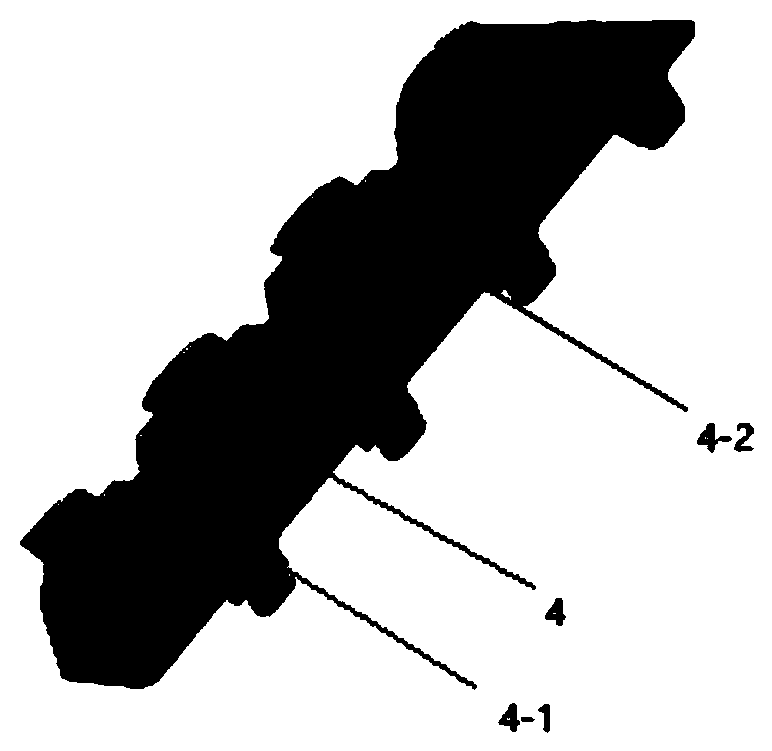

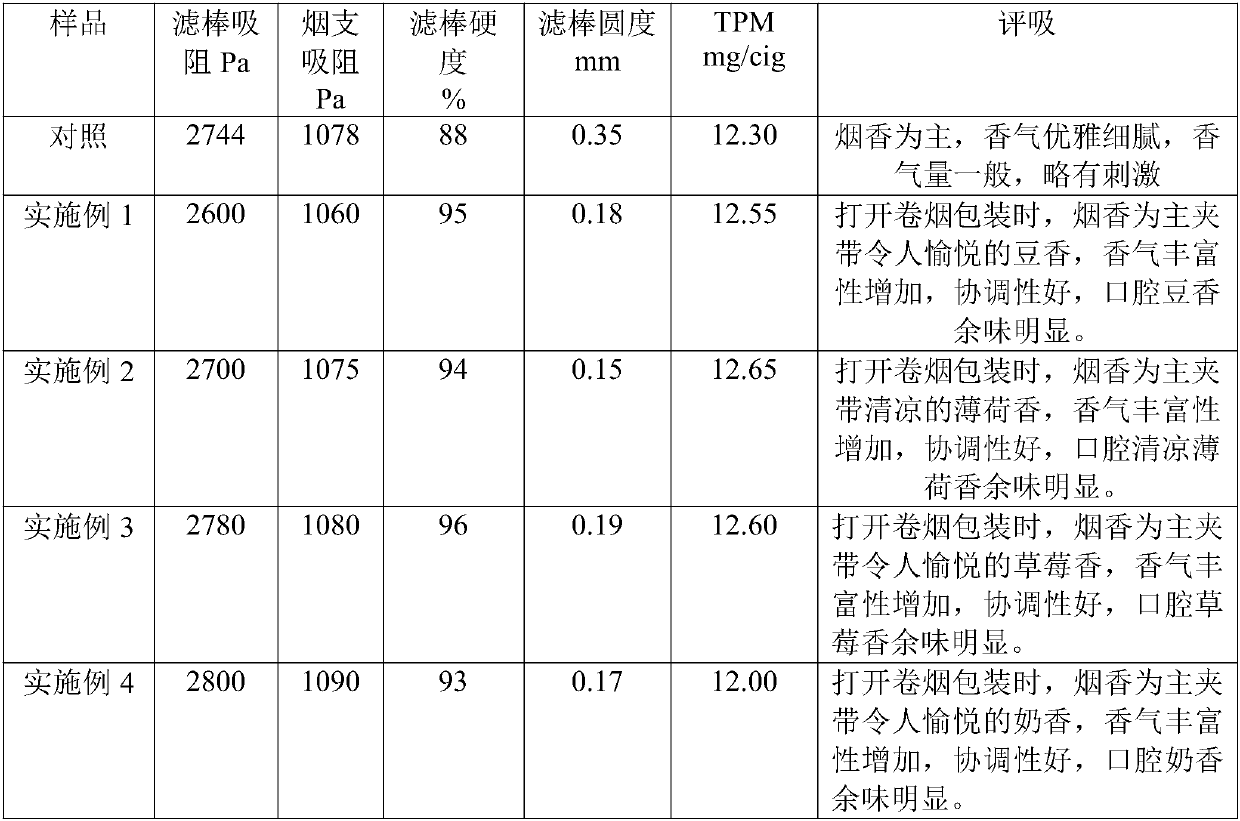

[0087] Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder (for example Leistritz ZSE MAXX): 1) screw rod 4 is 20 An equidistant screw, the thread 4-1 is a toothed thread with a height of 4mm; the head of the screw 4 is provided with 4 sets of equidistant grooves 4-2; the grooves 4-2 are evenly arranged along the outer periphery of the screw 4; The depth of the groove 4-2 on the head thread of the screw rod 4 is consistent with the height of the thread 4-1, and the width is 3mm; 2) the die 5 with an inner diameter of 7.0mm is connected with a glass tube 7 with an inner diameter of 7.5mm, The round pipe 7 surrounds the air-cooled cooler 6 around.

[0088] 1) Remove impurities from the corncobs, then cook, sterilize, sterilize, and dry them in the sun; 2) Mechanically crush and screen out 20-80 mesh corncob particles, and balance the...

Embodiment 2

[0090] Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder (for example Leistritz ZSE MAXX): 1) screw rod 4 is 20 Equidistant screw, the thread 4-1 is a toothed thread 4-1 with a height of 4mm; the head of the screw 4 is provided with 3 groups of equidistant grooves 4-2; Evenly arranged; the depth of the groove 4-2 on the head thread of the screw rod 4 is consistent with the height of the thread 4-1, and the width is 3mm; 2) the die 5 with an inner diameter of 7.2mm is connected with a glass circle with an inner diameter of 7.5mm Pipe 7, circular pipe 7 surrounds air-cooled cooler 6 all around.

[0091] 1) Remove impurities from the walnut shell sticks, then cook, sterilize, and dry them in the sun; 2) Mechanically crush and screen out 20-80 mesh walnut shell particles, and balance the water content to 8% for use; 3) Mix peppermint...

Embodiment 3

[0093]Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder (for example Leistritz ZSE MAXX): 1) screw rod 4 is 20 An equidistant screw, the thread 4-1 is a toothed thread with a height of 4 mm; five groups of equidistant grooves 4-2 are arranged on the head of the screw 4; the grooves 4-2 are evenly arranged along the outer periphery of the screw 4; The depth of the groove 4-2 on the head thread of the screw rod 4 is consistent with the height of the thread 4-1, and the width is 3mm; 2) the die 5 with an inner diameter of 6.8mm is connected with a glass tube 7 with an inner diameter of 7.5mm, The round pipe 7 surrounds the air-cooled cooler 6 around.

[0094] 1) Remove impurities from coffee husks and coconut husks, then cook, sterilize, and dry them in the sun; 2) Mechanically crush and screen out 20-80 mesh coffee husks and coconu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com