Automatic cooked noodle processing equipment

A processing equipment and noodle technology, which is applied in the field of automated cooked noodle processing equipment, can solve problems such as not being able to supply in time, and achieve the effect of saving manpower and time and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

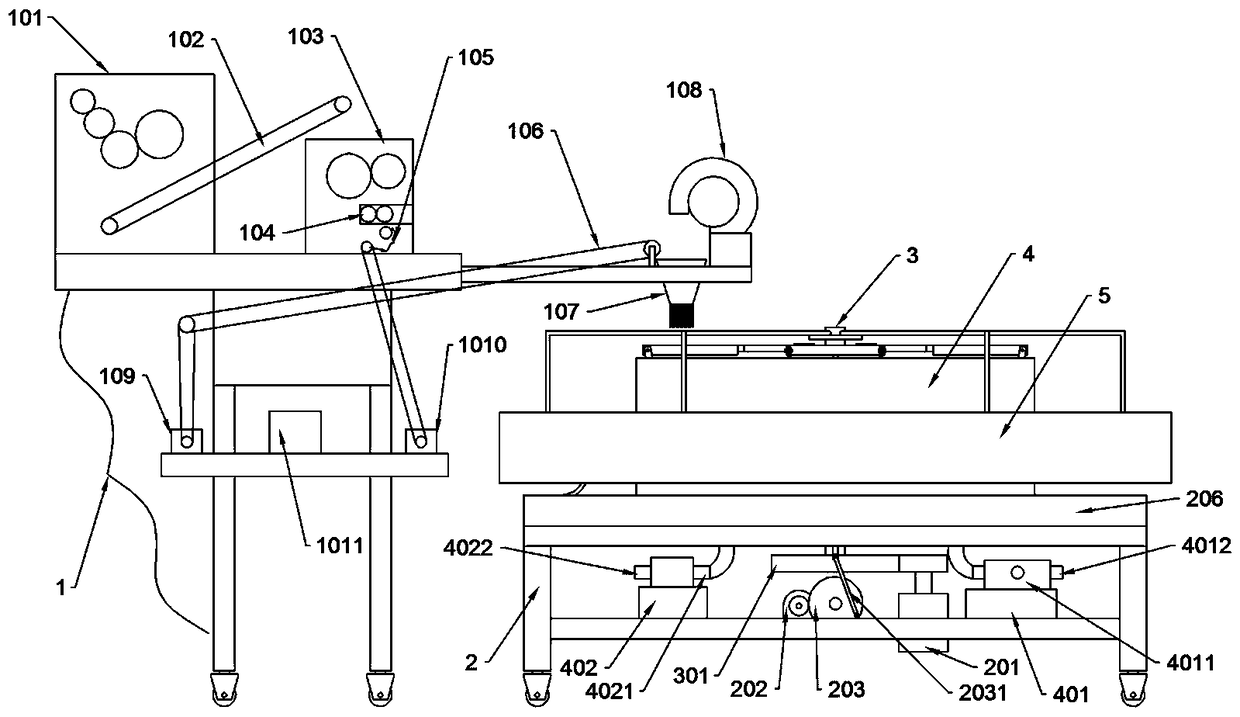

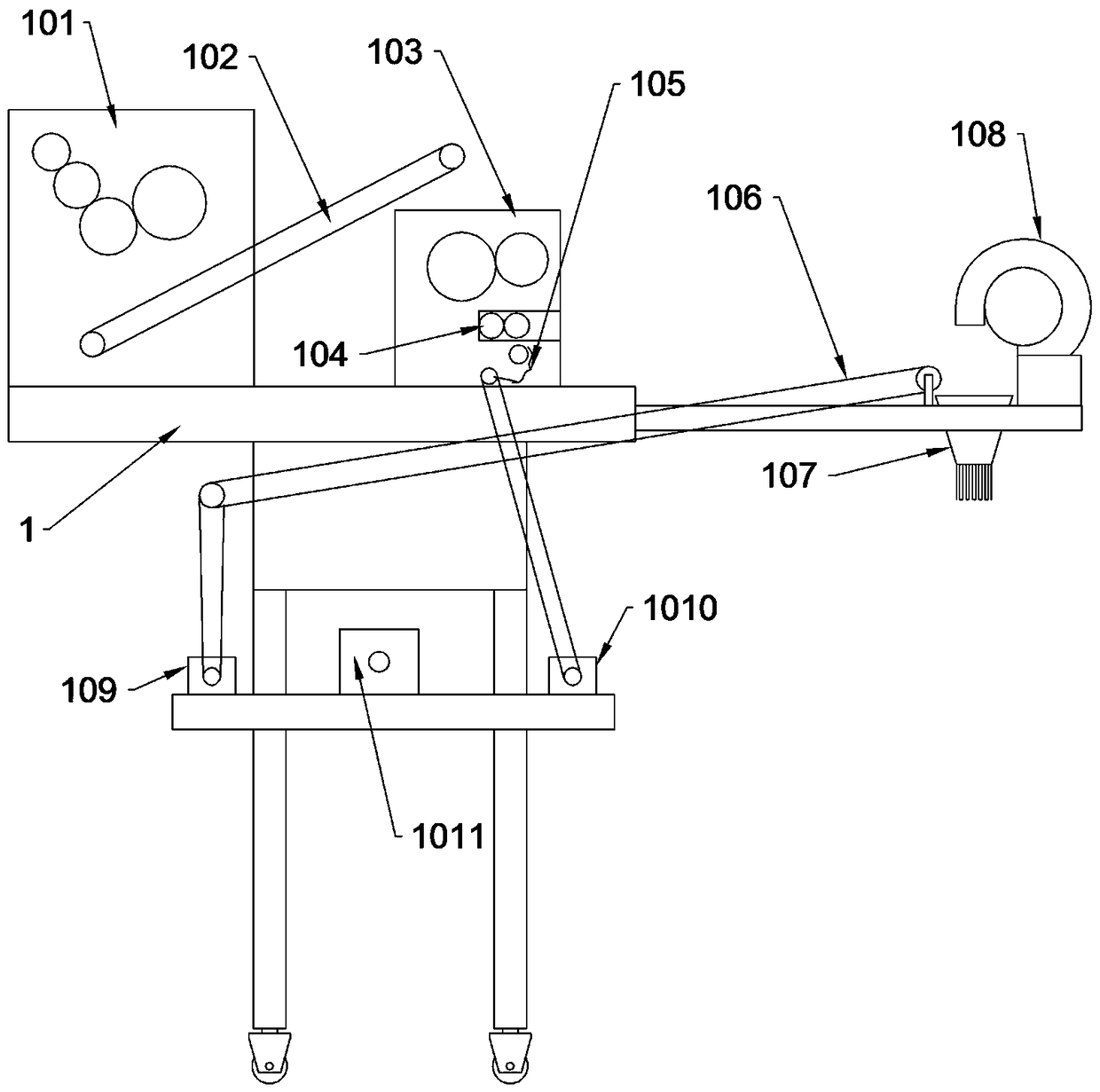

[0037] In the present invention, the structures of the noodle pressing mechanism 101 for the first time, the noodle conveyor belt 102, the noodle pressing mechanism 103 for the second time and the noodle knife 104 are all prior art, wherein the noodle pressing mechanism 101 for the first time, the noodle conveyor belt 102 and the noodle pressing mechanism for the second time Mechanism 103 is specifically described in another published patent filed by the applicant. The application number of this patent is 201720674590.5, and the name of the invention is an automatic hemp leaf machine, and the noodle knife 104 is a known technology. Therefore, for the initial pressing mechanism 101 , the structure of the noodle conveyor belt 102, the secondary noodle pressing mechanism 103 and the noodle knife 104 will not be described in detail.

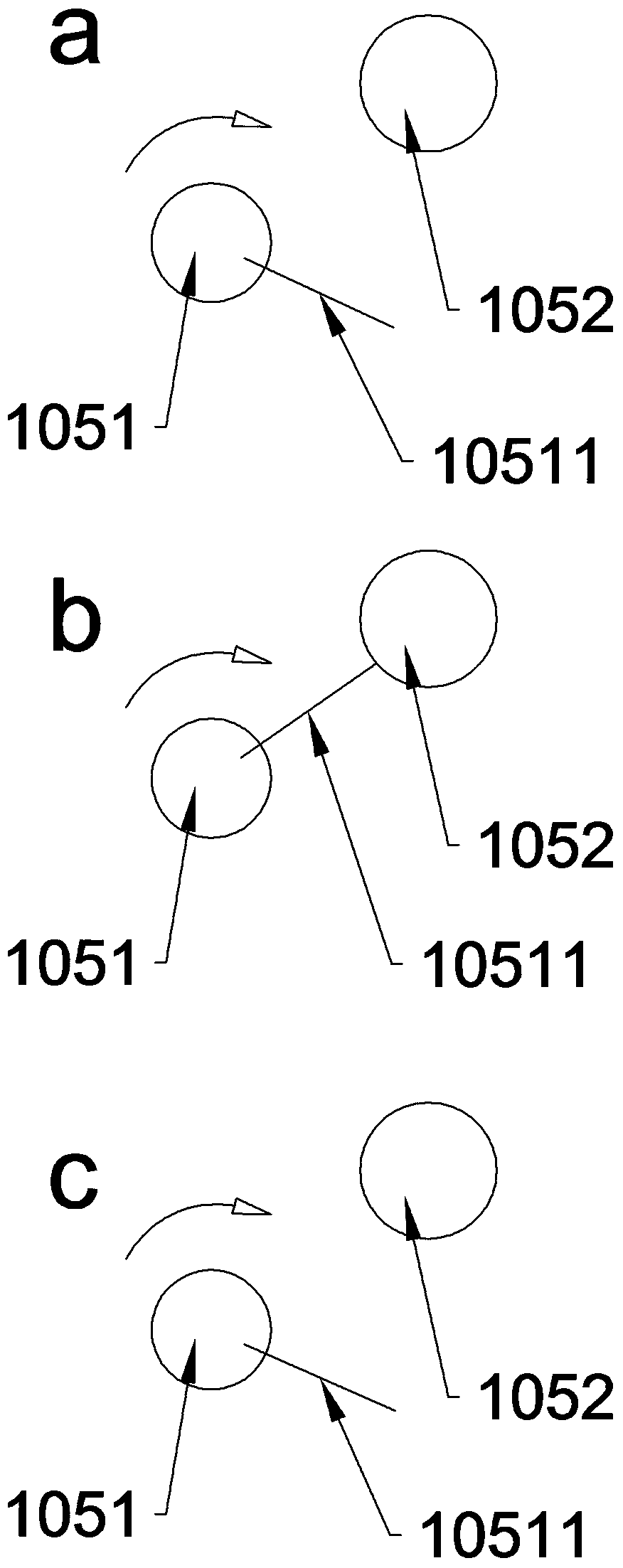

[0038] The specific embodiment of the present invention sees Figure 1-12 :

[0039]A kind of automatic cooked noodle processing equipment, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com