Leak detection system and leak detection method of flange, welding seam, pipeline or equipment body

A pipeline and flange technology, applied in the field of thermal insulation engineering, can solve the problems of failure to detect leakage in time, failure to effectively reduce the probability and loss of serious accidents, and achieve the effect of effective detection, reduction of probability of occurrence, and good market value.

Active Publication Date: 2019-01-01

赵俊芳

View PDF16 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since most of the pipeline network is covered with heat insulation materials, the leakage phenomenon is difficult to be found in time, and it is easy to cause heavy losses

Although there is a combination of configuration software monitoring and manual inspection in the existing pipeline leak detection system, it is still unable to detect the occurrence of leakage and locate the leak point in time. Such a pipeline leak detection system may miss the last time to take measures. Even if the timing is the best, it cannot effectively reduce the probability of serious accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

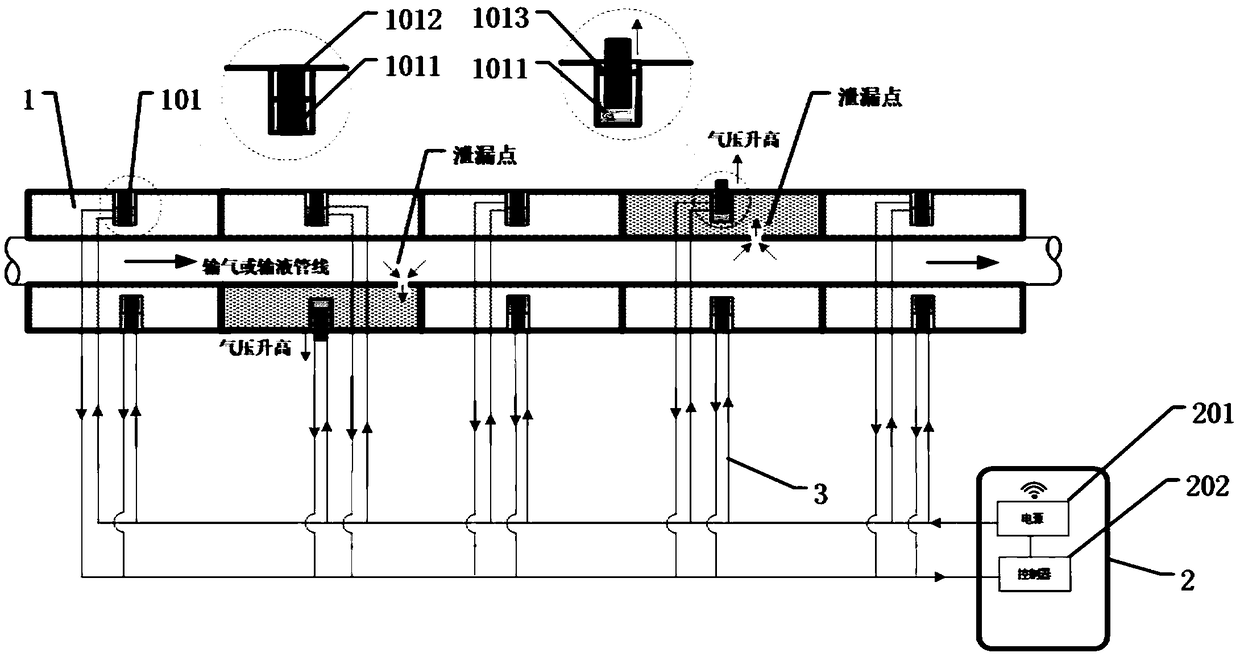

[0030] The airtight cavity 1 is fastened together by two semicircular heat insulation boxes.

[0031] The piezoelectric transmitter 1013 is piezoelectric ceramics.

Embodiment 2

[0033] The airtight cavity 1 is composed of a C-shaped pipe heat insulation box.

[0034] The energy storage chamber 1011 adopts elastic capsule type.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the leak detection system of a flange, a welding seam, a pipeline or an equipment body. The system is mainly formed by a closed cavity, a detection unit and a connection lead.The closed cavity is wrapped on the outer side of the tested flange, the welding seam, the pipeline or the equipment body. Each closed cavity is embedded with a micropressure transmitter and is codedby a controller. All the micropressure transmitters are connected in parallel through using the connection lead and are connected to the detection unit. The closed cavity has heat insulation and leakage point detection functions. By using the system of the invention, the early-stage leakage of the flange, the welding seam, the pipeline or the equipment body can be timely discovered, a caution isemitted and accurate leakage point positioning is performed so that measures can be timely taken and the generation probability of a major accident is reduced. A technical scheme which combines electronic monitoring and manual inspection is adopted, the difficulty and intensity of the manual inspection are reduced, and the result of the electronic monitoring is manually and regularly inspected sothat the dual guarantee of the real-time monitoring of an operation equipment state is realized. The system can carry out safe and effective detection and has a good market value.

Description

technical field [0001] The invention relates to the field of heat insulation engineering and on-line detection, in particular to a leak detection system and method for flanges, welds, pipelines or equipment bodies. Background technique [0002] The pipeline network in the chemical plant is criss-crossed, and there are many dynamic and static equipment, and there are a lot of flammable and explosive media in it. During production and operation, the leakage of these media is very dangerous. However, since most of the pipeline network is covered with heat insulation materials, the leakage phenomenon is difficult to be found in time, and it is easy to cause heavy losses. Although there is a combination of configuration software monitoring and manual inspection in the existing pipeline leak detection system, it is still unable to detect the occurrence of leakage and locate the leak point in time. Such a pipeline leak detection system may miss the last time to take measures. Even...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/26G01M3/28

CPCG01M3/26G01M3/2815G01M3/2853G01M3/2884

Inventor 周天宇

Owner 赵俊芳

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com