Oil injection system, method and device

A technology of oil injection and oil injection volume, which is applied in the direction of engine components, engine lubrication, lubricating parts, etc., and can solve problems such as error-prone, inability to realize intelligent operation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

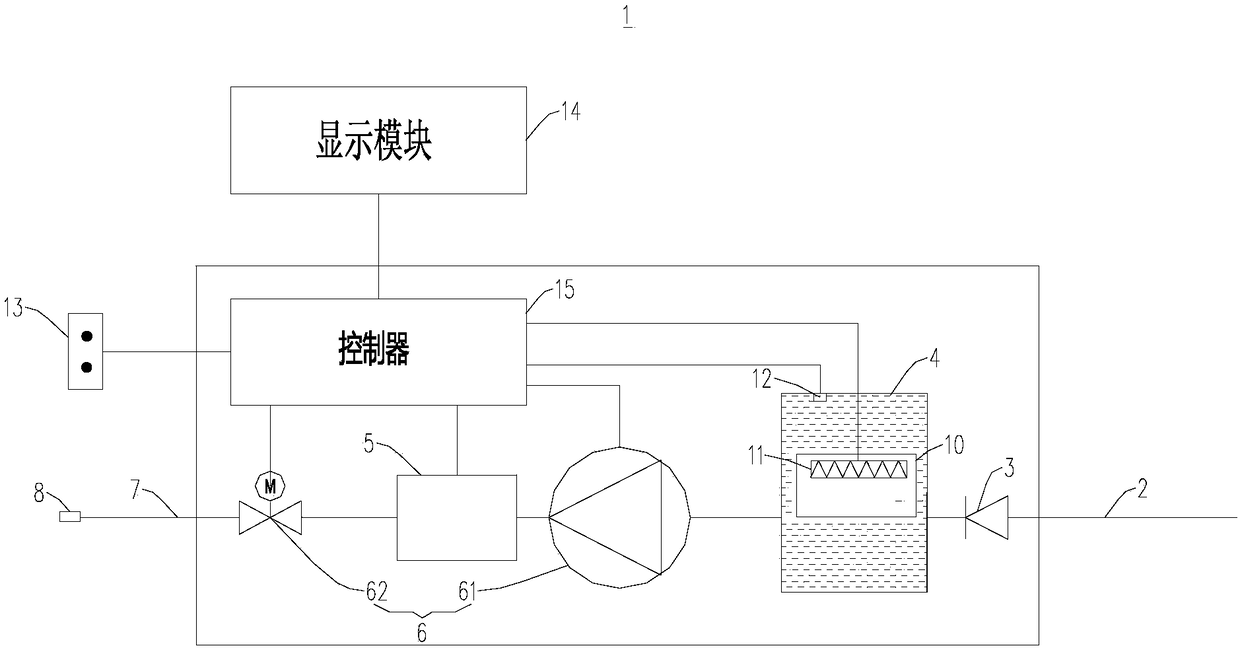

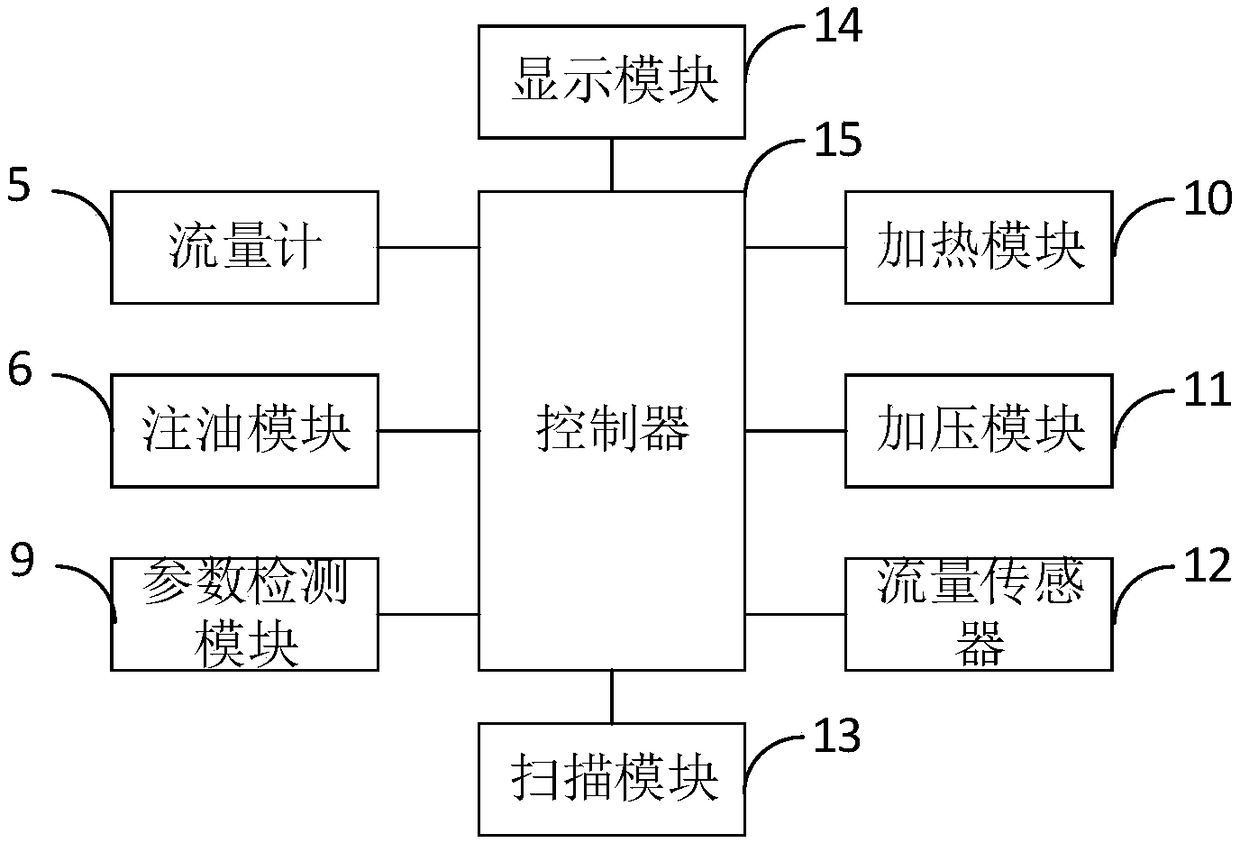

[0065] The embodiment of the present invention provides an oil injection system 1, which is used to realize online automatic oil injection for various components of an air conditioning system. see figure 1 , is a system block diagram of the oil injection system 1 provided by the embodiment of the present invention. The oil injection system 1 includes: oil suction pipe 2, check valve 3, oil storage module 4, flow meter 5, oil injection module 6, oil injection pipe 7, joint 8, parameter detection module 9, heating module 10, pressurization module 11, flow rate A sensor 12 , a scanning module 13 , a display module 14 and a controller 15 . Among them, the oil suction pipe 2, the check valve 3, the oil storage module 4, the flow meter 5, the oil injection module 6, the oil injection pipe 7 and the joint 8 are connected in sequence, and the parameter detection module 9, the heating module 10, the pressurization module 11 and the flow sensor 12 They are all arranged in the oil inje...

no. 2 example

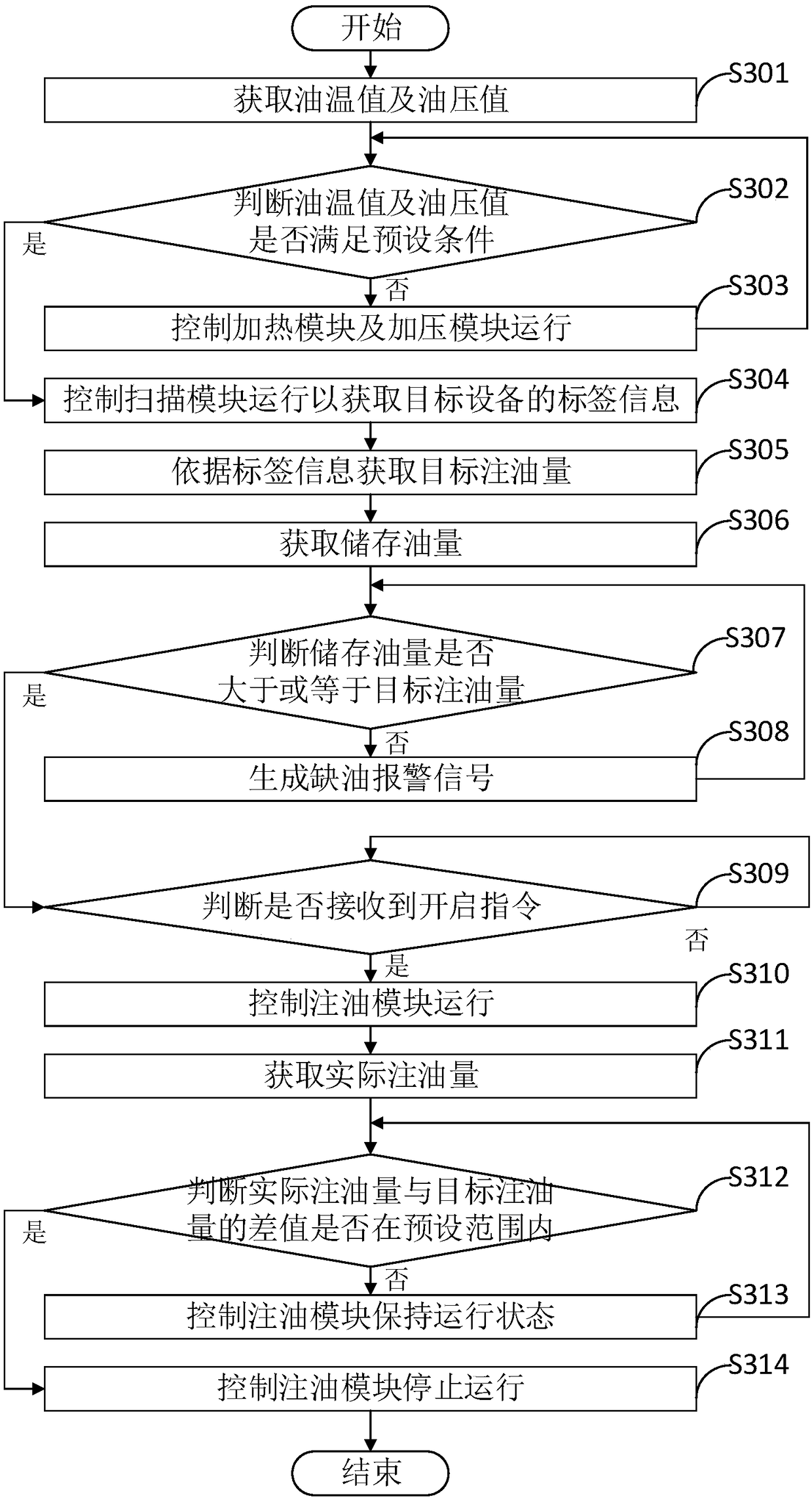

[0098] An embodiment of the present invention provides an oil injection method, which is applied to the oil injection system 1 provided in the first embodiment, and is used to realize online automatic oil injection for various components of the air conditioning system. see image 3 , is a flowchart of an oil injection method provided by an embodiment of the present invention. It should be noted that the basic principles and technical effects of the oil injection method provided in this embodiment are the same as those of the above-mentioned embodiments. content. The oil injection method that the embodiment of the present invention provides comprises:

[0099] Step S301: Obtain oil temperature and oil pressure.

[0100]Understandably, the oil temperature value and the oil pressure value are respectively collected and transmitted by the oil temperature sensor and the pressure sensor.

[0101] Step S302: judging whether the oil temperature value and the oil pressure value mee...

no. 3 example

[0125] The embodiment of the present invention provides an oil injection device 16, which is applied to the oil injection system 1 provided in the first embodiment, and is used to realize online automatic oil injection for various components of the air conditioning system. see Figure 4 , is a functional block diagram of an oil injection device 16 provided by an embodiment of the present invention. It should be noted that the basic principles and technical effects of the oil injection device 16 provided in this embodiment are the same as those of the above-mentioned embodiment. Corresponding content. The oil injection device 16 provided by the embodiment of the present invention includes: a parameter acquisition unit 17 , a judgment unit 18 , a control unit 19 , a tag information acquisition unit 20 , an oil quantity information acquisition unit 21 and an alarm signal generation unit 22 .

[0126] Wherein, the parameter acquisition unit 17 is used to acquire oil temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com