ZSM-35 molecular sieve preparation method

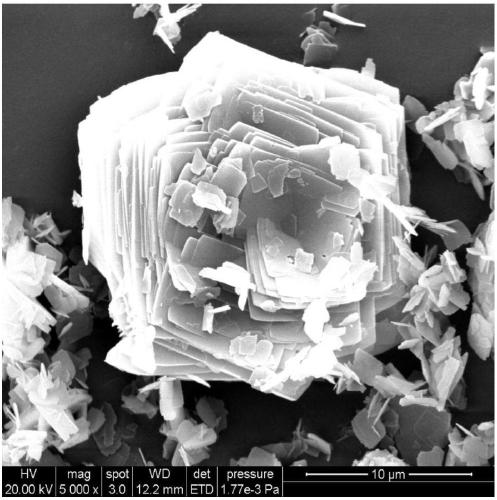

A ZSM-35 and molecular sieve technology, applied in the field of ZSM-35 molecular sieve preparation, can solve the problems of inability to guarantee the stability of isobutene-selective catalysts, long residence time in pores, poor diffusion performance, etc., and achieve excellent catalytic performance and voids between molecular sieves. The effect of large, small thickness and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

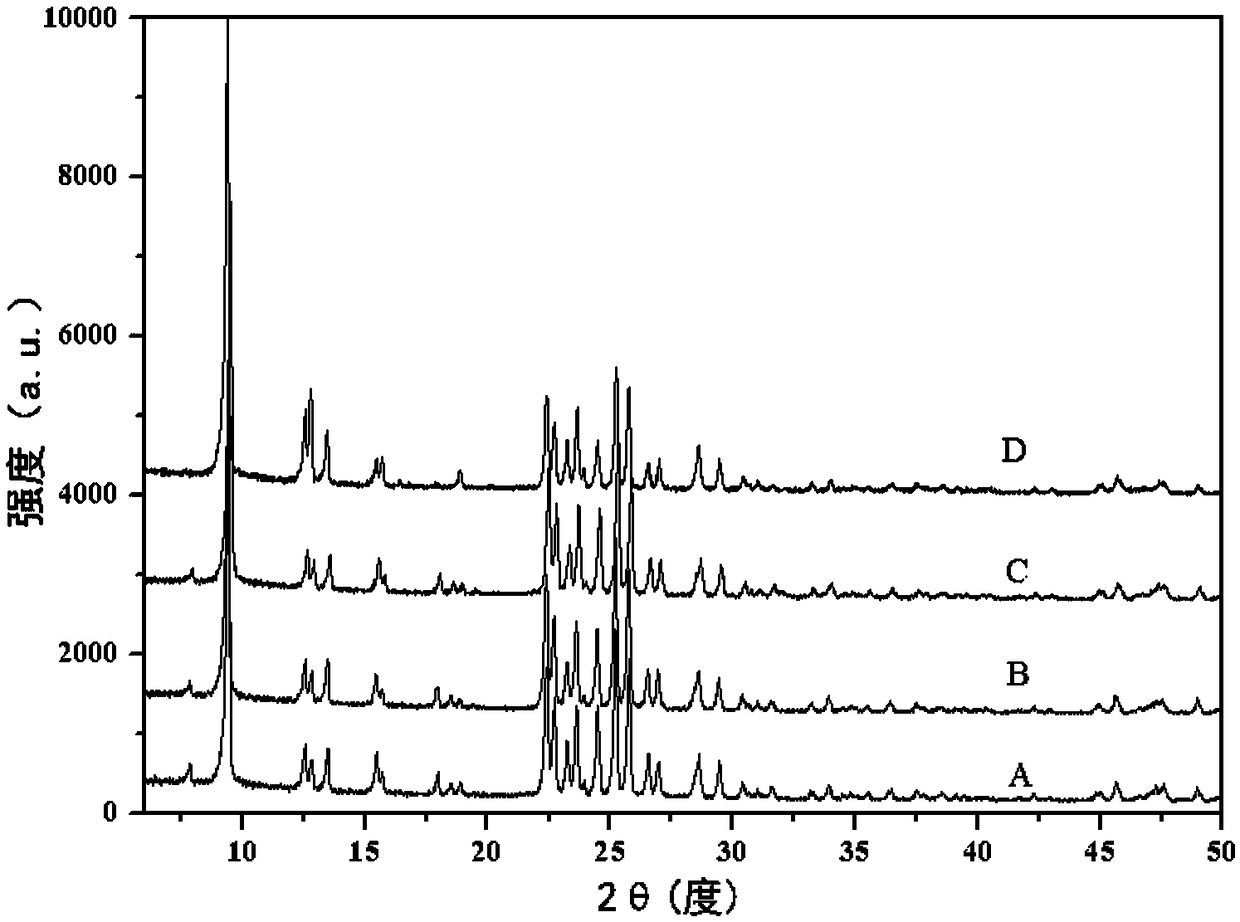

Embodiment 1

[0045] Step A, under the condition of 40 ℃, 600g silica sol (SiO 2 content is 25%) and 0.28g sodium hydroxide join in 1440g distilled water, add 31.9g aluminum sulfate (Al 2 o 3 content is 16%), continue to stir for a period of time until the solution is uniform, slowly add 114.7g of pyridine, and then add 21g of ethylenediamine to obtain a ZSM-35 molecular sieve mixture;

[0046] The molar ratio of the obtained ZSM-35 molecular sieve mixture is Al 2 o 3 : 50SiO 2 : 1600H 2 O: 7 organic template agent I + 29 organic template agent II: 0.14OH - ;

[0047] Step B, heating the ZSM-35 molecular sieve mixture at a stirring speed of 300 rpm to 180° C., and crystallizing at a constant temperature for 20 hours to obtain a crystallized ZSM-35 molecular sieve mixture;

[0048] Step C, filter, wash and dry the crystallized ZSM-35 molecular sieve mixture at 120°C, transfer the dried molecular sieve to a muffle furnace for calcination at 400°C, and finally obtain nanosheets ZSM-35 ...

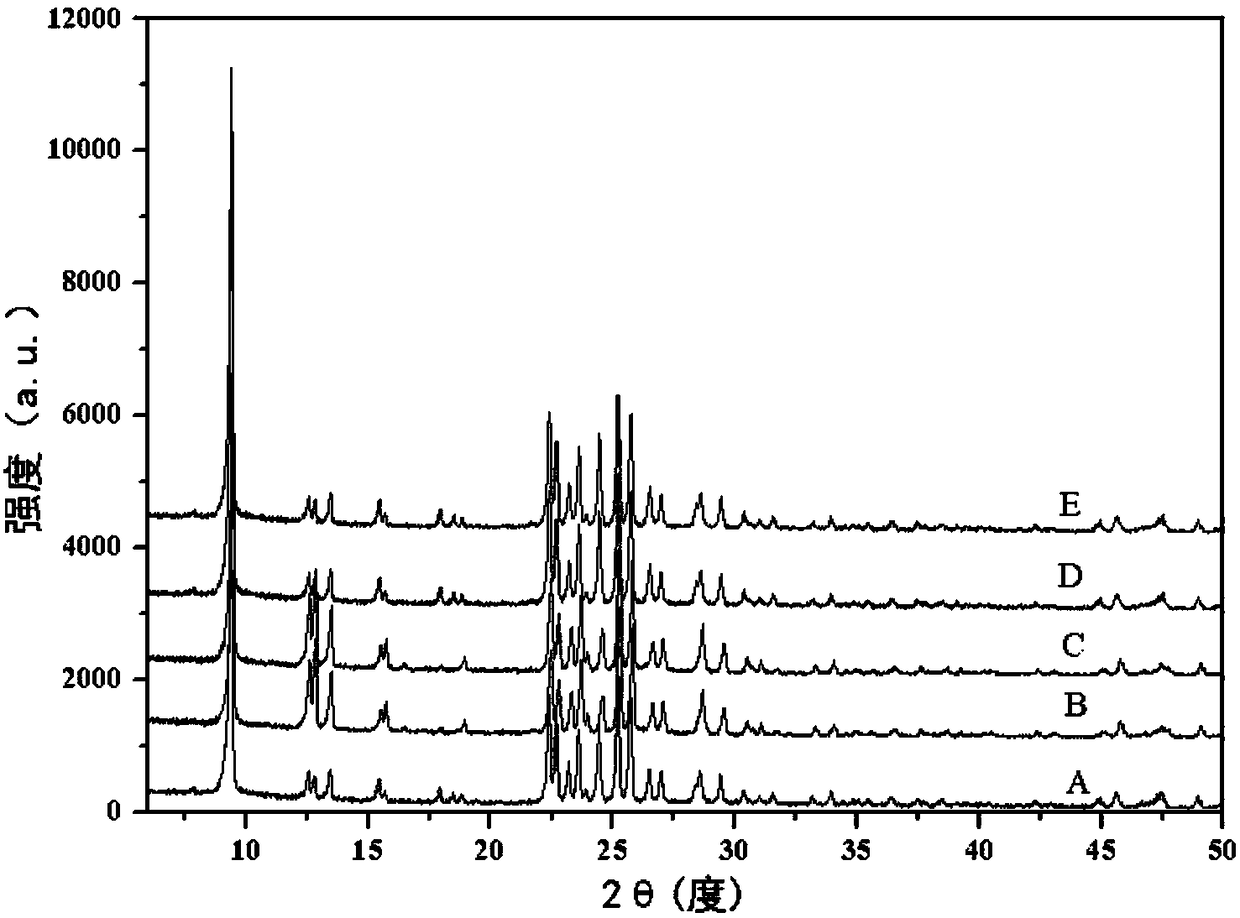

Embodiment 2

[0051] The difference from Example 1 is that the gelling temperature is changed to 50°C, the amount of sodium hydroxide is changed to 0.32g, the amount of distilled water is changed to 1620g, the amount of pyridine is changed to 102.8g, and the first organic template is changed to cyclo Hexylamine, the dosage is 29.7g, the order of adding the first organic template agent and the second organic template agent is changed to be added at the same time, the crystallization temperature is changed to 190°C, the constant temperature crystallization time is changed to 24h, and the drying temperature is changed to 130°C , the calcination temperature was changed to 450°C, and the rest of the components and conditions remained unchanged;

[0052] The molar ratio of the obtained ZSM-35 molecular sieve mixture is Al 2 o 3 : 50SiO 2 : 1800H 2 O: 6 organic template agent I + 26 organic template agent II: 0.16OH - .

[0053] The obtained sample is analyzed by BET, and the specific surface...

Embodiment 3

[0055] The difference from Example 1 is that the gel forming temperature is changed to 30° C., the amount of silica sol is changed to 720 g, the amount of sodium hydroxide is changed to 0.3 g, the amount of distilled water is changed to 1350 g, and the second organic template is changed to piperin Pyridine, the consumption is 102.2g, the order of adding the first organic template agent and the second organic template agent is changed to first add the first organic template agent and then the second organic template agent, the constant temperature crystallization time is changed to 24h, and the drying temperature is changed to 24h. is 140°C, the calcination temperature is changed to 450°C, and the rest of the components and conditions remain unchanged;

[0056] The molar ratio of the obtained ZSM-35 molecular sieve mixture is Al 2 o 3 : 60SiO 2 : 1500H 2 O: 7 organic template agent I + 24 organic template agent II: 0.15OH - .

[0057] The obtained sample was analyzed by BE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com