Machining method of split sleeve

A technology of a slotted bushing and a processing method, which is applied in the processing field of slotted bushings, can solve the problems of strong adhesion, difficulty in success, and the loss of dry film lubricant, and achieves the effect of prolonging the service life and improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

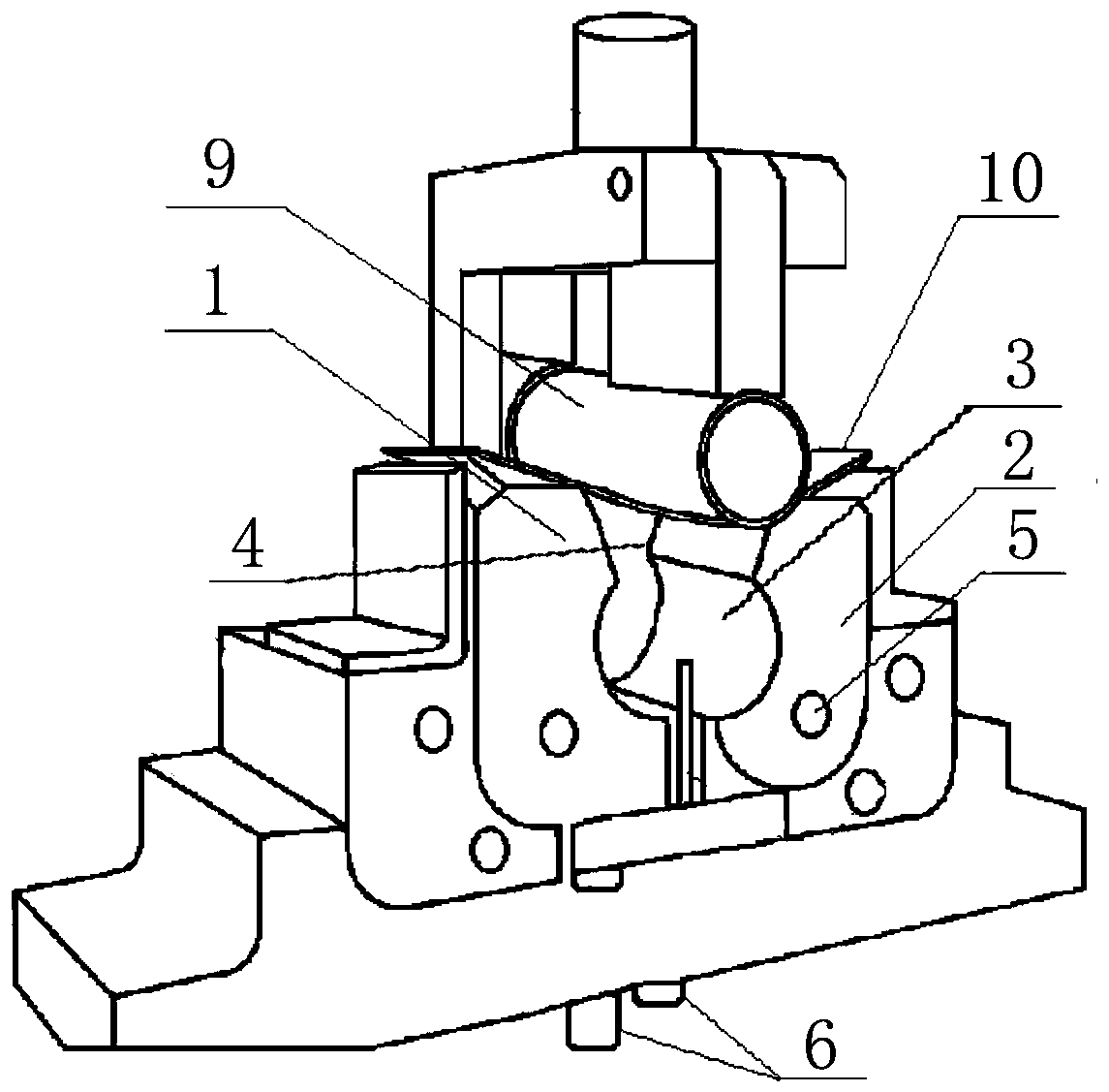

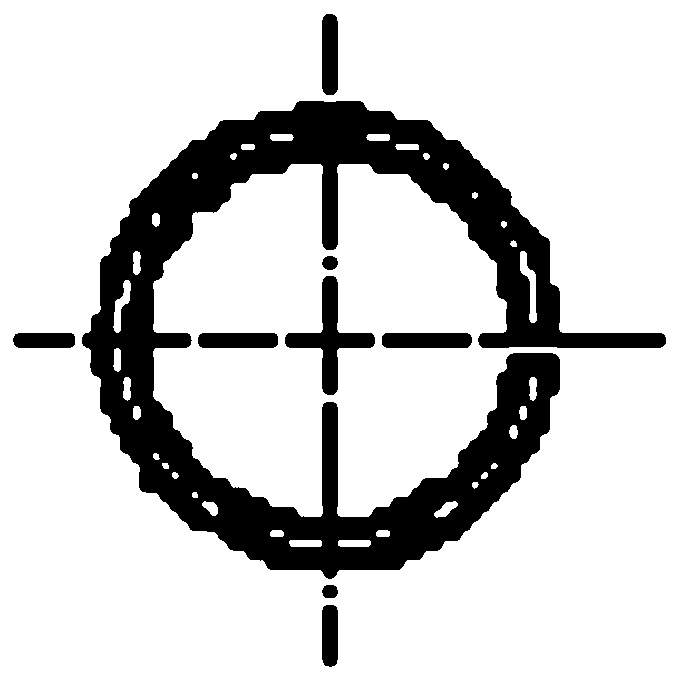

[0100] Figure 1-6 As shown in the figure, it is a slotted liner for cold extrusion hole reinforcement

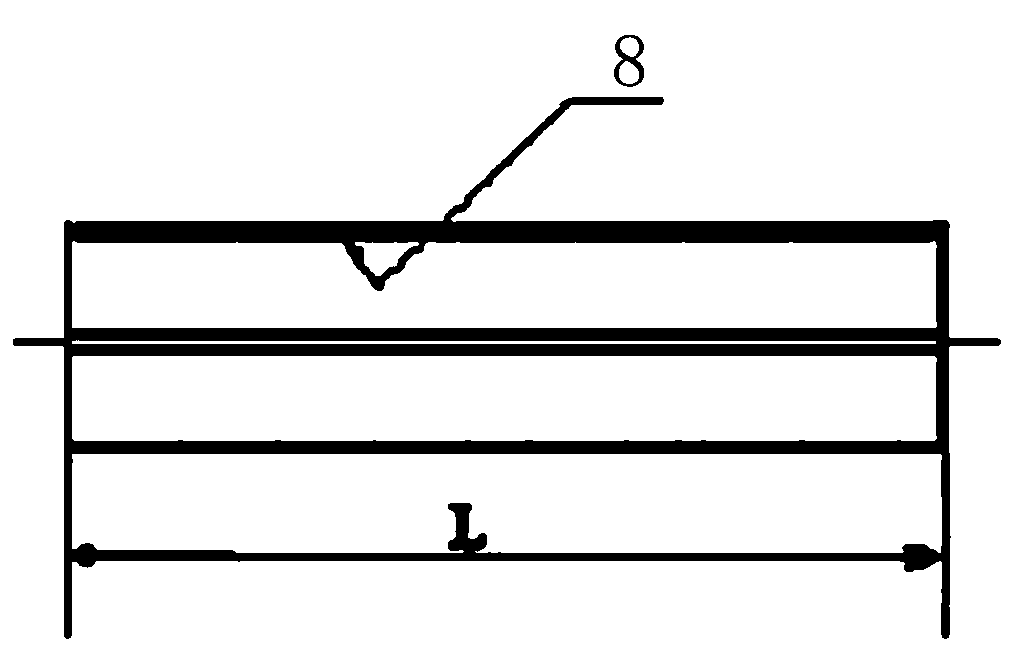

[0101] Production specification code CBS-8-3-N-16F, suitable for initial hole diameter of 0.283-0.286In (7.1882-7.2644mm), length of 1In (25.4 mm) slotted bushing for extruding reinforced fastener holes 5 / Take 16 In (7.9375 mm) as an example and include the following steps: According to the requirements of the cold extrusion specification, use a 1Cr17Ni7 high-strength stainless steel sheet with a thickness of 0.008 In. (0.2mm); Cut into strips. Before sample layout, calculate the blanking size of the casing according to the average value of the minimum and maximum diameters of the initial hole diameter before pressing. The expanded width is 21.78mm, and the length is 1In (25.4mm) plus the width of flange 7, which is about 27.4mm. When laying out samples, make the length axis of the stainless steel slit bushing consistent with the length direction of the stainless steel p...

Embodiment 2

[0103] The production specification code CBS-12-0-N-24F is suitable for the initial hole diameter of 0.359-0.362 In (9.119-9, 1948mm), and the length of 1-7 / 16In (36.5mm). The slotted bush is used for extruding strong fasteners The fastener hole with a hole diameter of 3 / 8 (9.525mm) is taken as an example and the steps are as follows: According to the specification requirements, choose to use a 301 high-strength stainless steel sheet with a thickness of 0.01In (0. 25mm). The 301 stainless steel sheet has been heat-treated at the factory, and the thickness meets the requirements, so it is directly cut into strips. Before layout, calculate the blanking size of the casing according to the average value of the minimum and maximum diameters of the initial hole diameter before extrusion. The expanded width is 27.602mm, and the length is 1-7 / 16 In (36.5mm plus flange width about 38mm); layout Make the length axis of the stainless steel slit bushing consistent with the length directio...

Embodiment 3

[0105] The production specification code CBS-14-1-N-32F is applicable to the initial hole diameter of 0.437-0.440In (11.0998-11,176mm) and the length of 2 In (50.8mm). The 64 In (11.509 mm) hole is taken as an example and the steps are as follows: According to the specification requirements, choose to use a 0.01 In (0.25mm) 301 high-strength stainless steel sheet. The 301 stainless steel sheet has been heat-treated at the factory, and the thickness meets the requirements, so it is directly cut into strips. Before sample layout, calculate the blanking size of the casing according to the average value of the minimum and maximum diameters of the initial hole before extrusion. The expanded width is 33.57mm, and the length is 2In (50.8mm plus flange 7, the width is about 52mm); the stainless steel is slit during sample layout. The length of the bushing is axially aligned with the length of the stainless steel plate / coil. Before the stainless steel sheet is coated with dry film lub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com