Well-ordered photovoltaic module cleaning system

A photovoltaic module and cleaning system technology, applied in the direction of photovoltaic modules, photovoltaic power generation, cleaning methods using tools, etc., can solve the problem of increasing the work intensity of staff, low efficiency, unsuitability for the promotion of large-scale photovoltaic power plants, and increased investment costs, etc. Problems, to achieve the effect of being conducive to sunlight, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

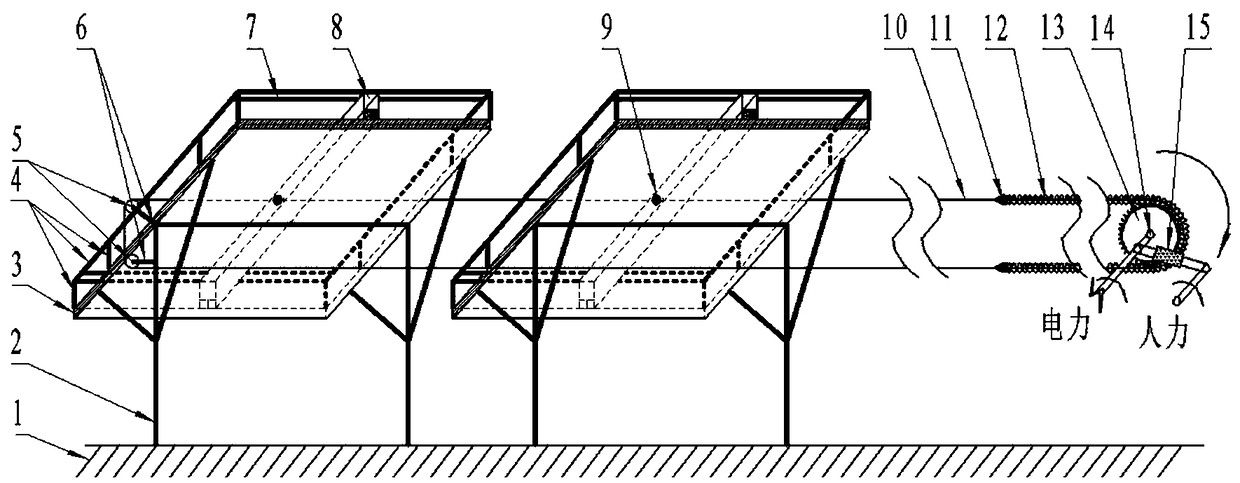

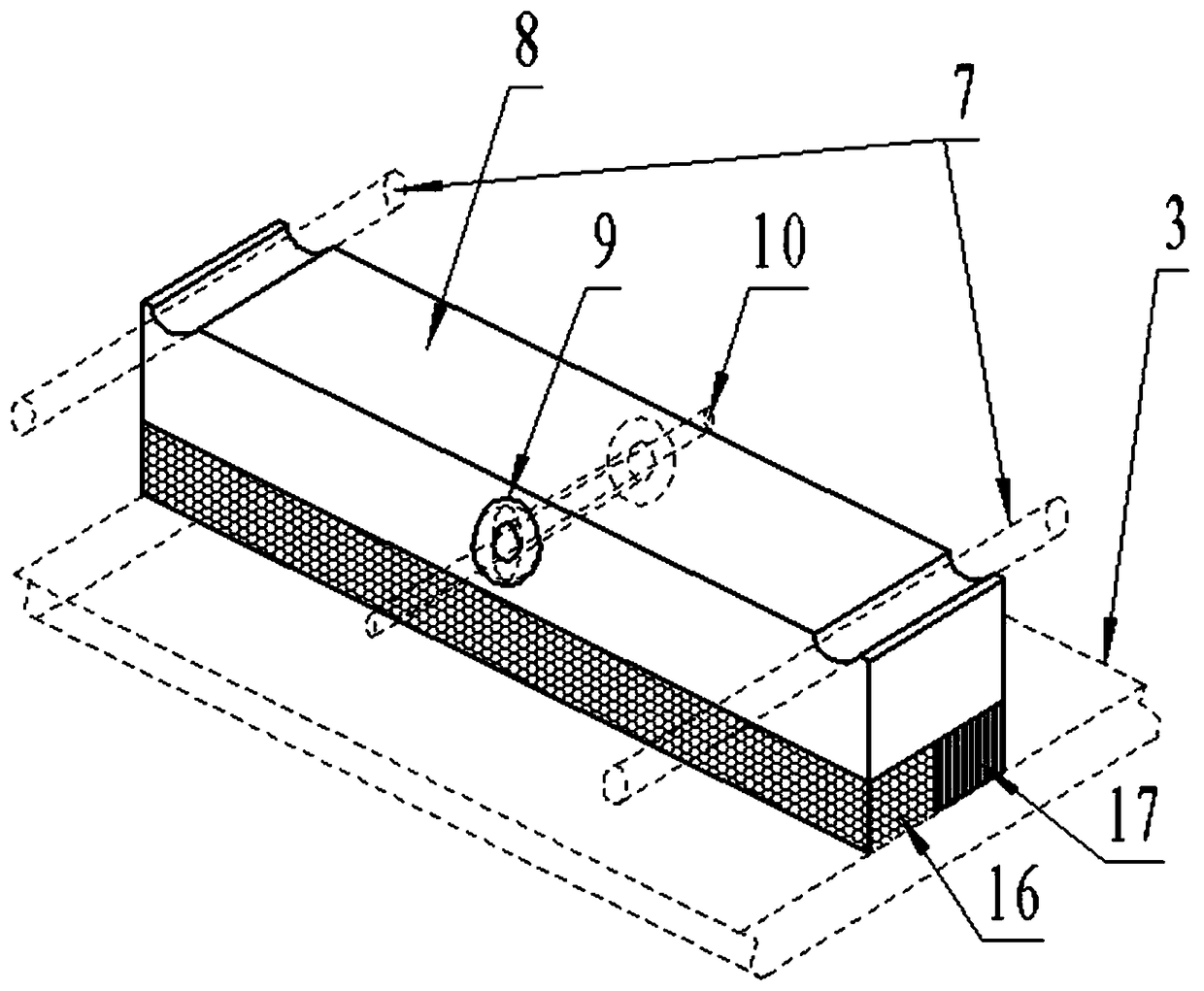

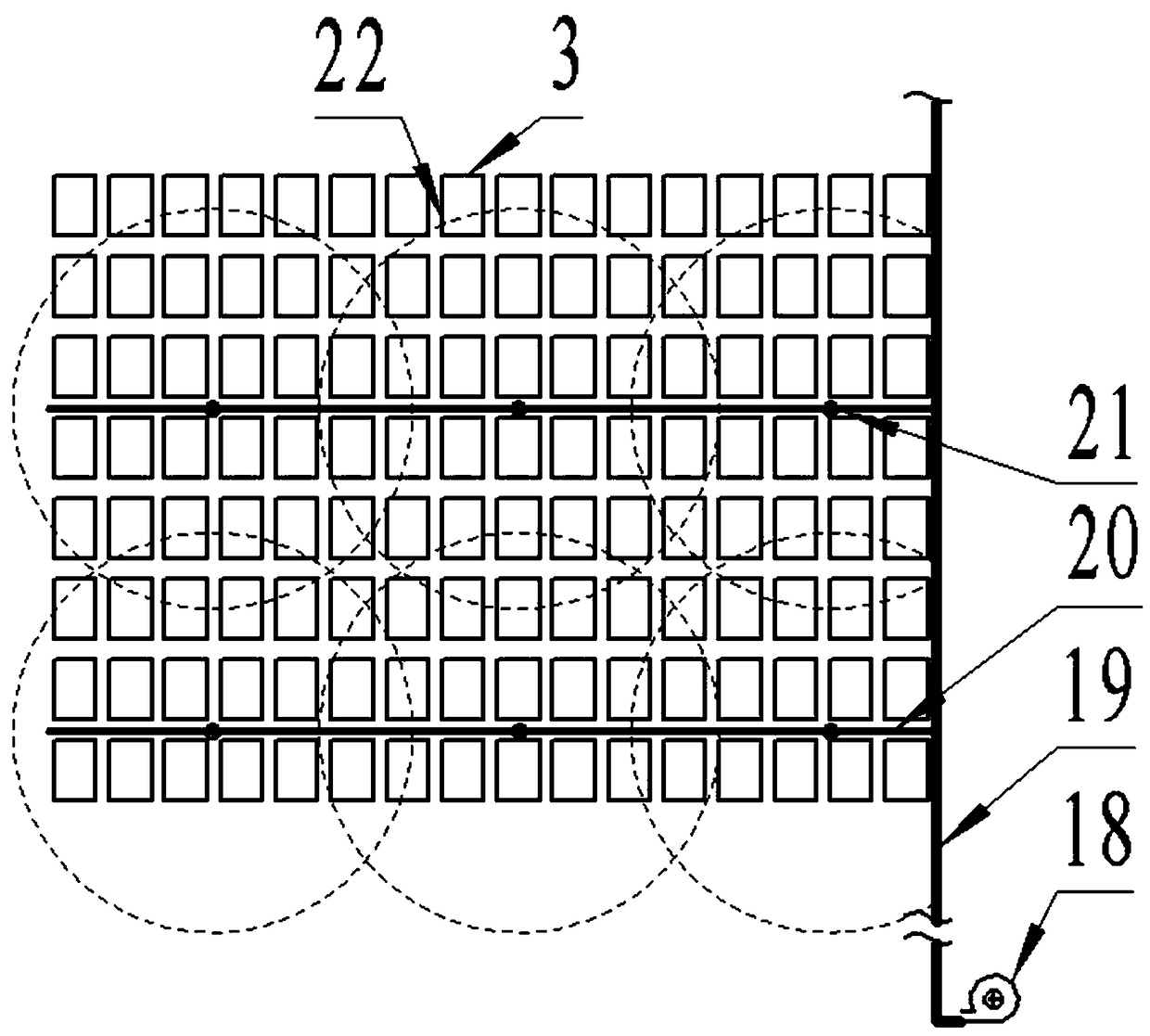

[0028] Such as figure 1 As shown, a neatly arranged photovoltaic module cleaning system includes two parts: a water spraying part and a cleaning part. During operation, the water spraying part is first turned on to wet the photovoltaic modules, and then the cleaning part is used to remove dust and dry the components.

[0029] The water spraying part includes a medium and high pressure nozzle water spraying assembly, a water delivery pipe network water distribution assembly and a power pump water supply assembly;

[0030] The cleaning part includes a transmission assembly, a cleaning assembly, a fixing assembly, and a power assembly; the transmission assembly includes a transmission chain and a transmission steel wire; the cleaning assembly includes absorbent cotton and a wiper; the fixing assembly includes a steel wire track fixing structure and a cleaning brush Track fixed structure; the power assembly includes power control function and human control function.

[0031] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com