Method for preparing phospholipid vesicle by utilizing highly oriented pyrolytic graphite

A pyrolytic graphite, highly directional technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical/physicochemical processes, etc., can solve the problems of poor uniformity of phospholipid vesicles, etc., to achieve The effect of fast formation, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

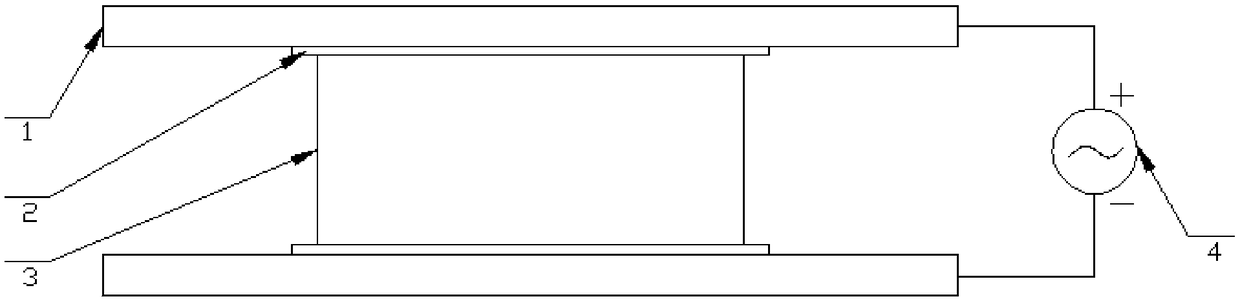

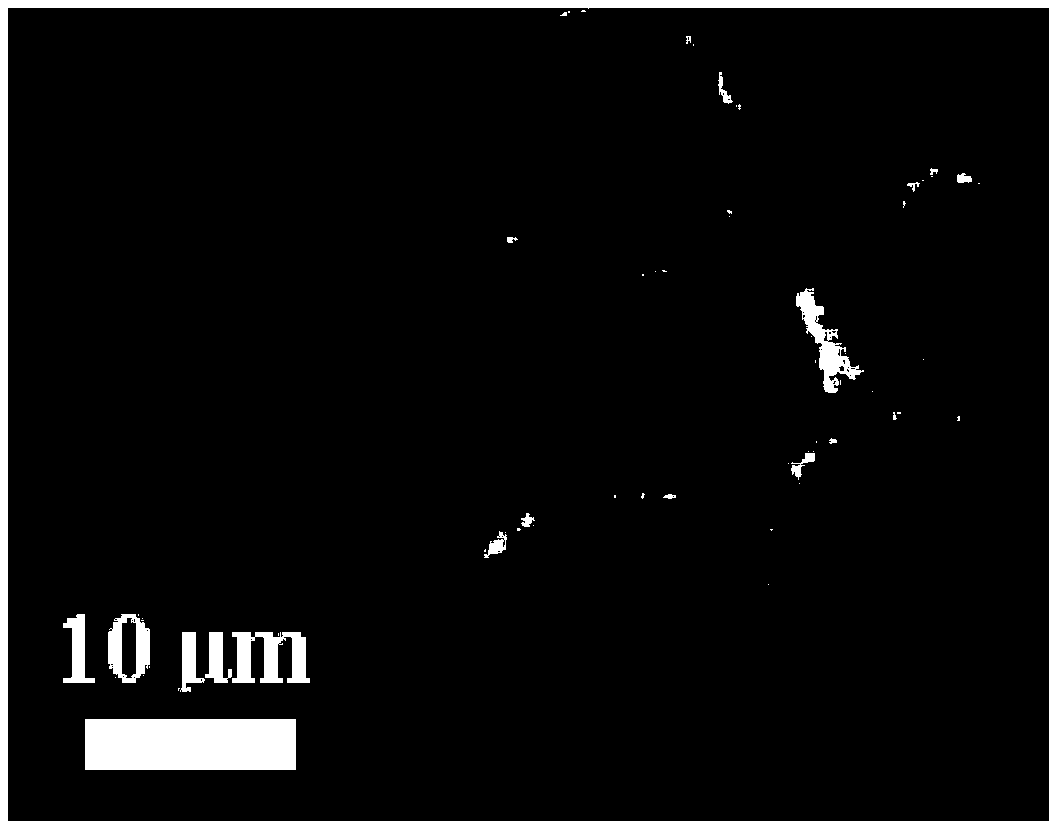

[0025] Embodiment 1: In this embodiment, the method for preparing phospholipid vesicles using highly oriented pyrolytic graphite as an electrode is carried out according to the following steps:

[0026] 1. Preparation of phospholipid solution

[0027] Dissolving phospholipids in ethanol to obtain a phospholipid solution;

[0028] 2. Preparation of planar highly oriented pyrolytic graphite electrodes loaded with phospholipid dry film

[0029] Uniformly coating the phospholipid solution prepared in step 1 on one surface of a planar highly oriented pyrolytic graphite electrode, and then vacuum-drying to obtain a planar highly oriented pyrolytic graphite electrode loaded with a phospholipid dry film;

[0030] 3. Assembling the reaction pool

[0031] Take two planar highly oriented pyrolytic graphite electrodes loaded with phospholipid dry film, place the two planar highly oriented pyrolytic graphite electrodes loaded with phospholipid dry film in parallel, and place the phosphol...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that the phospholipid in step 1 is dioleoyl phosphatidylcholine, 1-palmitoyl-2-oleoyl phosphatidylcholine or phosphatidylcholine. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0042]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass concentration of ethanol in step 1 is 99.95%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com