Biogas biological desulfurization system

A biological desulfurization and biogas technology, applied in the field of biogas biological desulfurization system, can solve the lack of biogas biological desulfurization system and other problems, achieve high precipitation and separation efficiency, improve precipitation and separation efficiency, and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

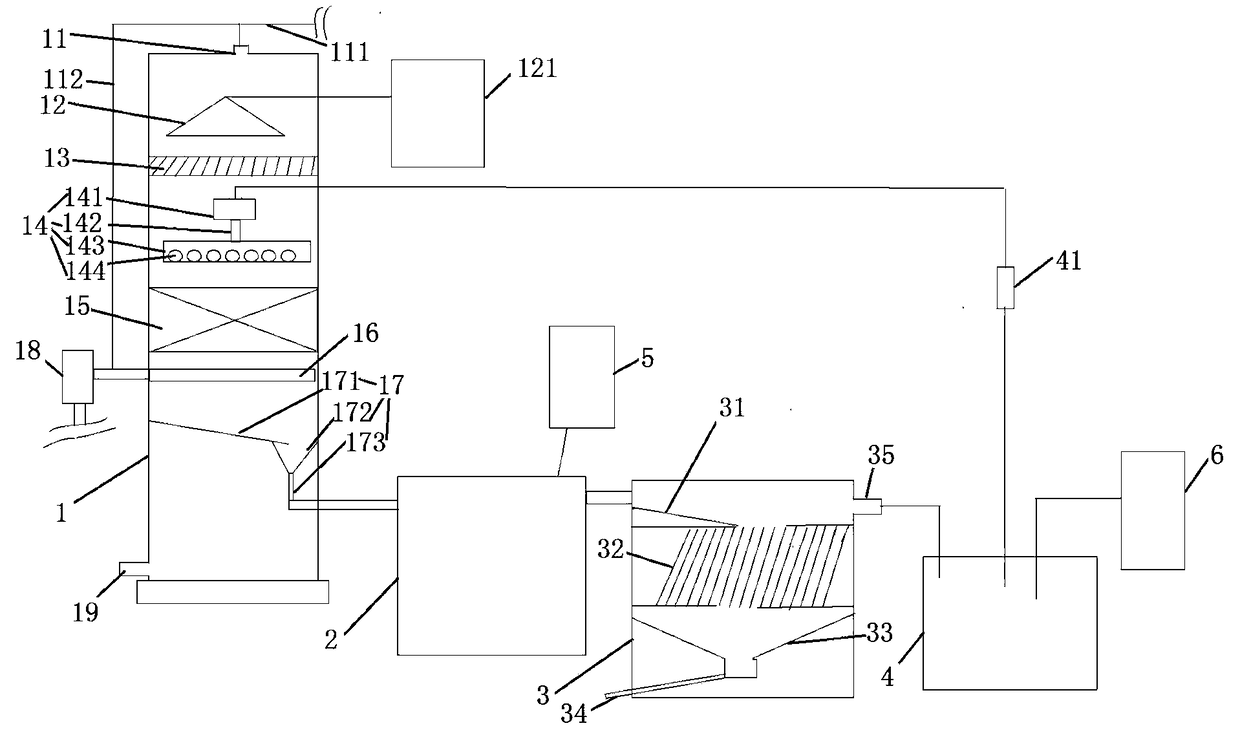

[0057] This embodiment provides a biogas biological desulfurization system, such as figure 1 As shown, the biogas desulfurization system in this embodiment includes: a chemical absorption tower 1 , a biological oxidation desulfurization tank 2 , a sedimentation tank 3 and a lye tank 4 . Specifically, the chemical absorption tower 1 is sequentially provided with a gas outlet 11, a lye distributor 14, a packing mechanism 15, an air inlet device 16, and a sulfur-containing lye collecting device 17 from top to bottom. Wherein, the biogas that enters the chemical absorption tower 1 by the air inlet device 16 passes through the packing mechanism 15 from bottom to top; The hydrogen sulfide in the biogas is absorbed to obtain sulfur-containing lye, the purified biogas is discharged from the gas outlet 11, and the sulfur-containing lye flows into the sulfur-containing lye collection device 17 under the action of gravity. The biological oxidation desulfurization pool 2 is connected wit...

Embodiment 2

[0060] Preferably, this embodiment provides a biogas desulfurization system, compared with the previous embodiment, such as figure 1 with figure 2 As shown, the present embodiment is further designed as follows:

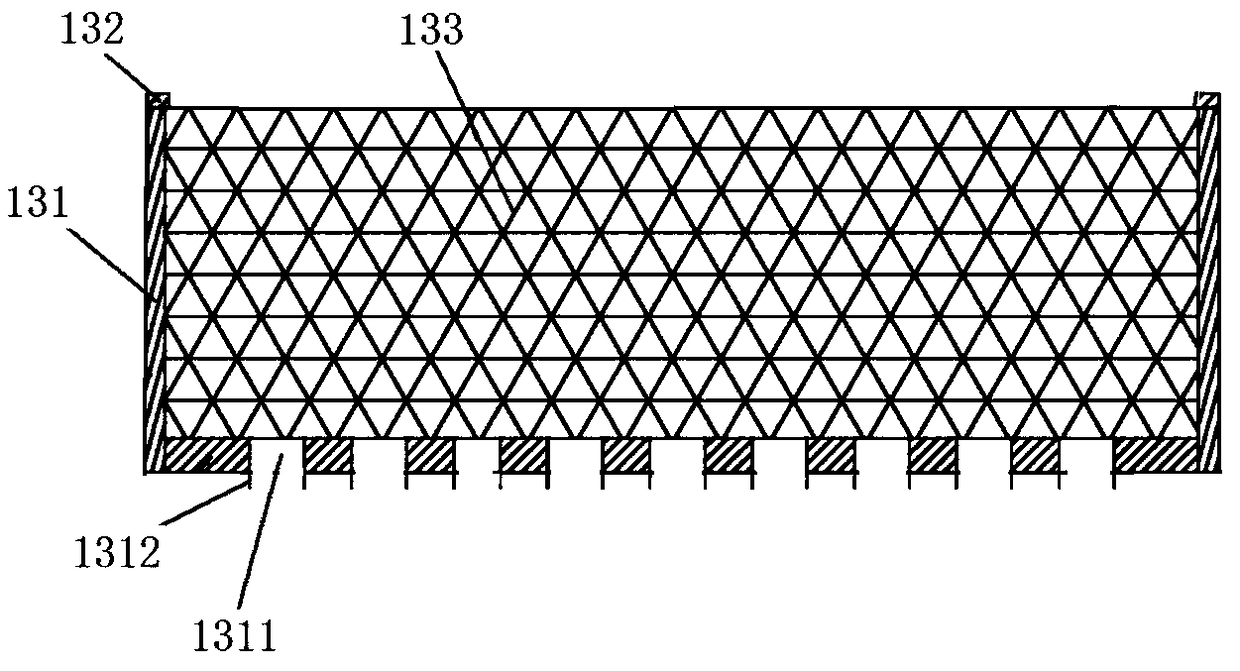

[0061] The chemical absorption tower 1 in the present embodiment is also provided with a demister 13, which is used to remove foam and mist in the biogas after sulfur removal; the demister 13 is located below the gas outlet 11, and the demister 13 is located at The top of the lye distributor 14; wherein the demister 13 includes: a limiting cavity 131 and a wire mesh block 133; wherein the limiting cavity 131 is a cylindrical structure, and the bottom of the limiting cavity 131 is provided with A plurality of ventilation holes 1311, each ventilation hole 1311 is provided with a drainage wire 1312 extending downward; the top of the limiting cavity 131 is open. The wire mesh block 133 is filled in the cavity formed by the limiting cavity 131 (the wire mesh block 133 ...

Embodiment 3

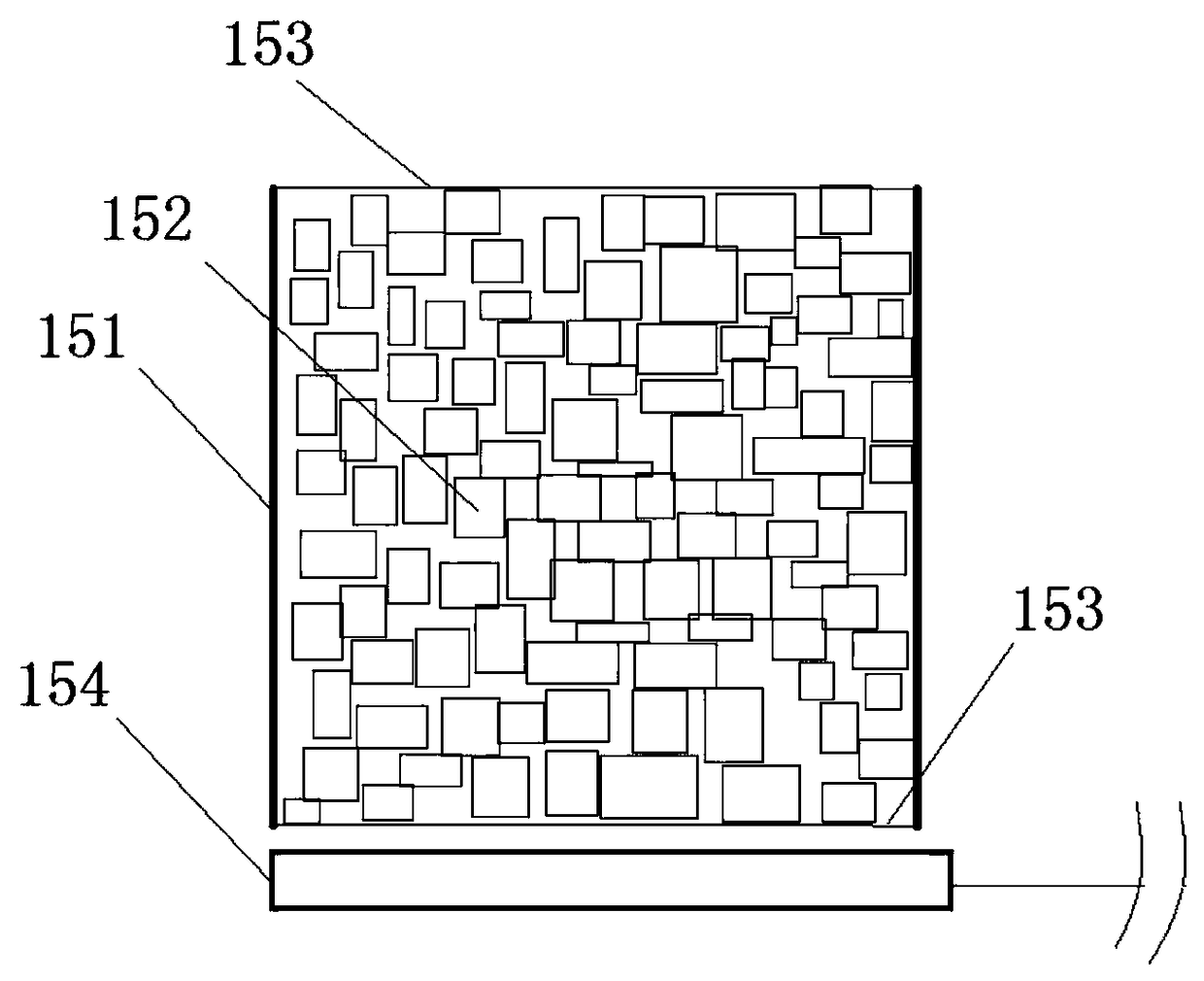

[0064] Preferably, this embodiment provides a biogas desulfurization system, compared with the previous embodiment, such as figure 1 As shown, the present embodiment further designs the chemical absorption tower as follows:

[0065] The chemical absorption tower 1 in the present embodiment is also provided with a spray scrubber 12; wherein, the spray scrubber 12 is positioned above the demister 13 and below the gas outlet 11; the chemical absorption tower 1 is provided with a water outlet 19 The spray scrubber 12 is used to communicate with the water system 121 outside the chemical absorption tower 1, and utilizes high-pressure water to clean the chemical absorption tower 1 and its internal components, such as demisters, lye distributors, packing mechanisms, etc.

[0066] In this embodiment, a washing and spraying device is installed near the top of the chemical absorption tower. When impurities attached to the tower affect the operation effect, the washing device is turned on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com