Drug release-controlled calcium phosphate bone cement composite microsphere and preparation method and application thereof

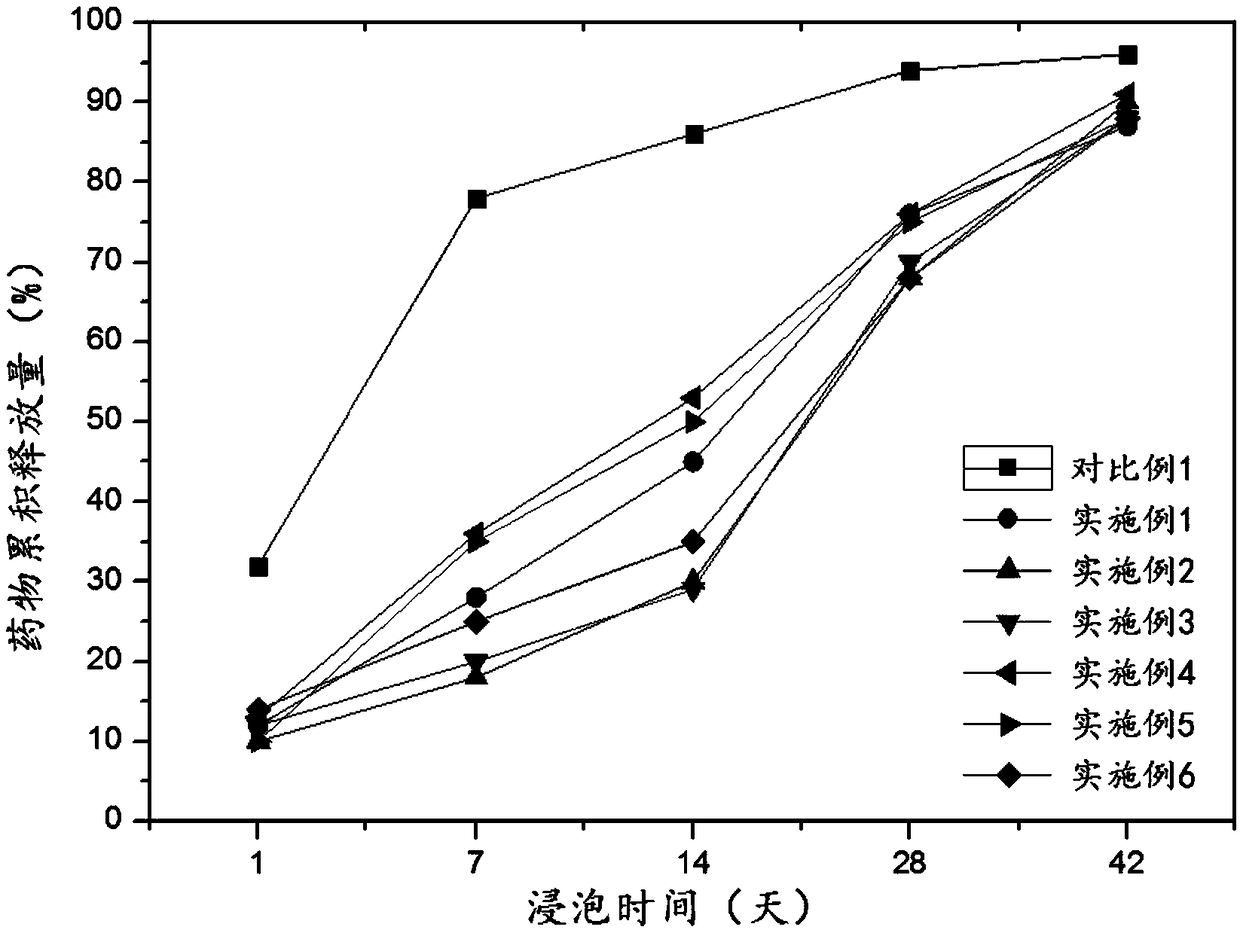

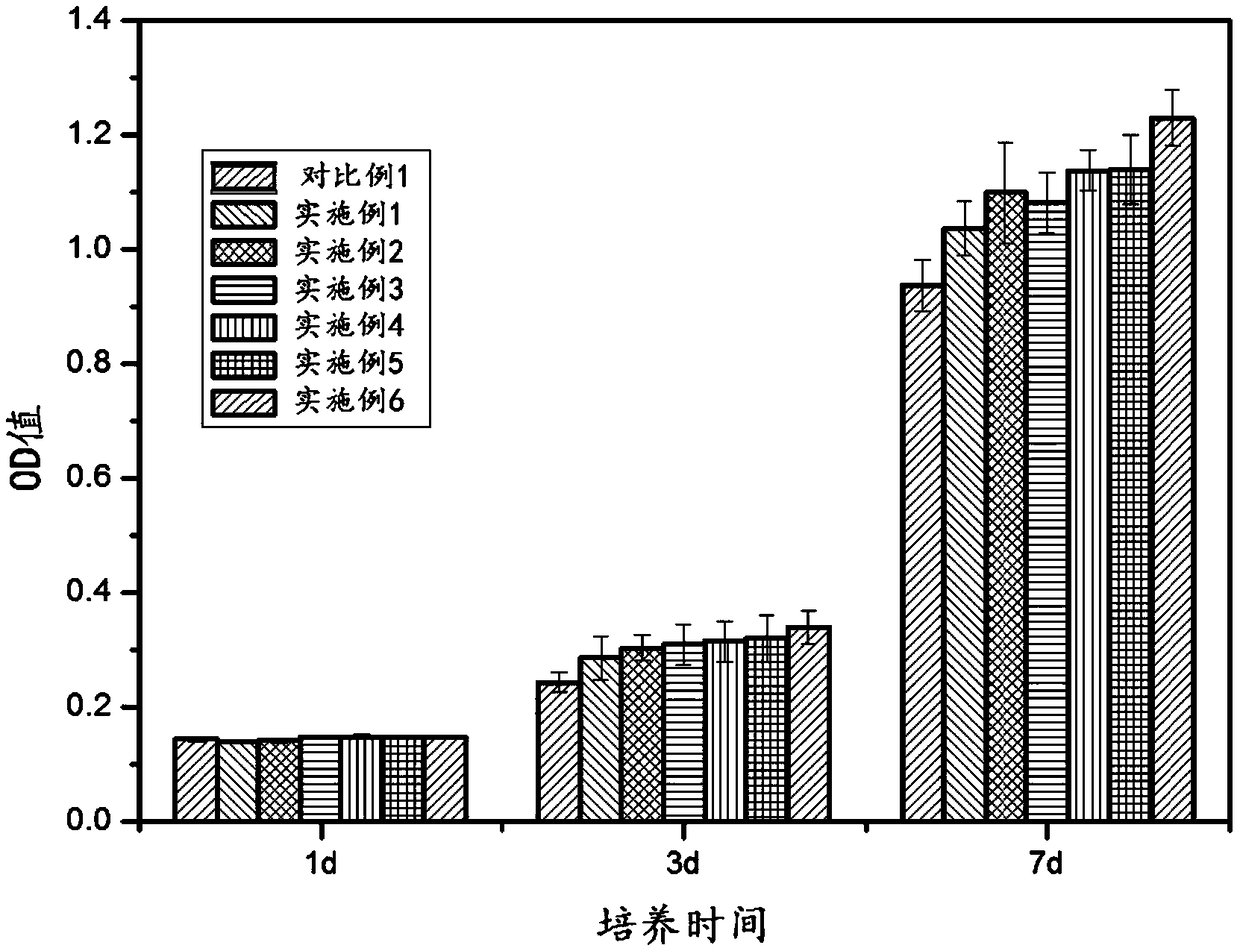

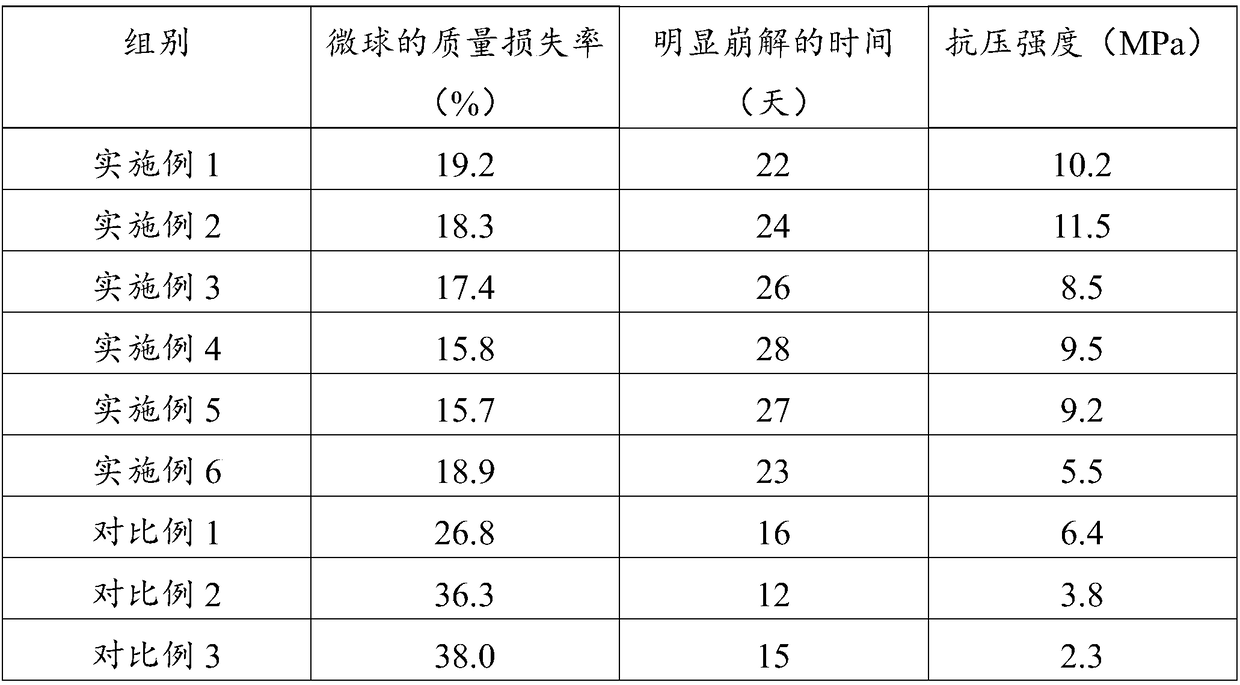

A technology of calcium phosphate bone cement and composite microspheres, which can be used in drug delivery, pharmaceutical formulations, and medical science. It can solve the problems of uncontrollable drug release rate, slow degradation of scaffolds, and unfavorable rapid bone healing. It achieves good biological activity and Effects of degradability, promotion of cell proliferation, good disintegration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] As an embodiment of the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres of the present invention, the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres described in this embodiment comprises the following steps:

[0039] (1) sodium alendronate is dissolved in water to obtain a drug solution, and the mass fraction of sodium alendronate in the drug solution is 1%; The mass ratio is 100:0.5, after ultrasonic treatment for 30 minutes, centrifugation and drying to obtain drug-loaded mesoporous calcium silicate;

[0040] The preparation method of the mesoporous calcium silicate is: adding calcium hydroxide to deionized water, adding ethanol, and stirring evenly to obtain a calcium hydroxide solution, the mass fraction of ethanol in the calcium hydroxide solution being 5%; Add ethyl orthosilicate dropwise into the calcium hydroxide solution, stir for 3-6 hours, centrifug...

Embodiment 2

[0047] As an embodiment of the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres of the present invention, the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres described in this embodiment comprises the following steps:

[0048] (1) sodium alendronate is dissolved in water to obtain a drug solution, and the mass fraction of sodium alendronate in the drug solution is 1%; The mass ratio is 100:0.6, after ultrasonic treatment for 30 minutes, centrifugation and drying to obtain drug-loaded mesoporous calcium silicate;

[0049] The preparation method of the mesoporous calcium silicate is: adding calcium hydroxide to deionized water, and adding ethanol, and stirring evenly to obtain a calcium hydroxide solution, and the mass fraction of ethanol in the calcium hydroxide solution is 4%; Add ethyl orthosilicate dropwise into the calcium hydroxide solution, stir for 3-6 hours, cent...

Embodiment 3

[0056] As an embodiment of the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres of the present invention, the preparation method of the drug controlled release calcium phosphate bone cement composite microspheres described in this embodiment comprises the following steps:

[0057] (1) sodium alendronate is dissolved in water to obtain a drug solution, and the mass fraction of sodium alendronate in the drug solution is 3%; The mass ratio is 100:0.6, after ultrasonic treatment for 50 minutes, centrifugation and drying to obtain drug-loaded mesoporous calcium silicate;

[0058] The preparation method of the mesoporous calcium silicate is: adding calcium hydroxide to deionized water, adding ethanol, and stirring evenly to obtain a calcium hydroxide solution, the mass fraction of ethanol in the calcium hydroxide solution being 5%; Add ethyl orthosilicate dropwise into the calcium hydroxide solution, stir for 3-6 hours, centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com