A resistor and a method for manufacturing the resistor

A manufacturing method and technology of resistors, applied in the direction of resistor manufacturing, resistors, resistor components, etc., can solve the problems of resistance element thickness limitation, use power limitation, complex process, etc., achieve shortened production cycle, strong heat dissipation, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is an embodiment of a resistor.

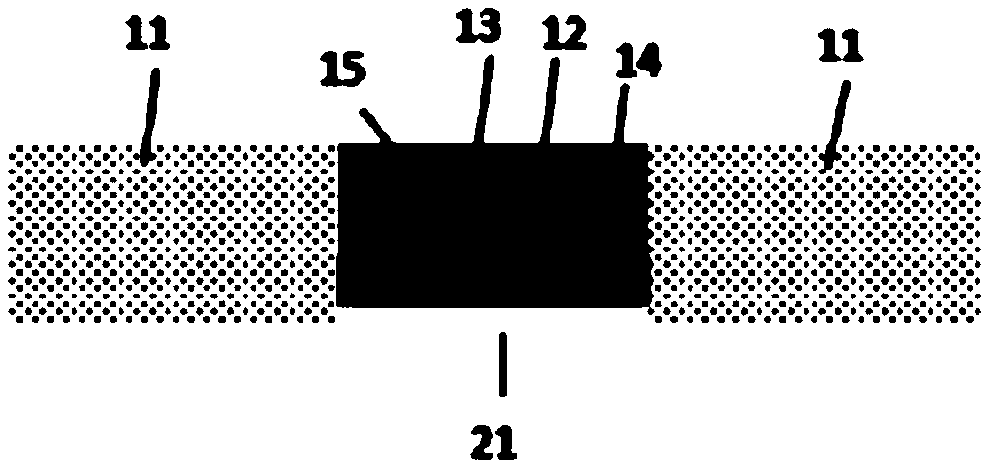

[0040] see figure 1 As shown, this embodiment provides a resistor 10 including a resistor unit 12 having an upper surface 13 and a lower surface 14 . The resistance unit 12 may be an alloy material with a low temperature coefficient of resistance such as manganese-copper-tin, nickel-chromium-aluminum-silicon or iron-chromium-aluminum. The lower surface of the resistance unit 12 has a trimming region 15 , and the preset resistance value of the resistance unit 12 is obtained by trimming the resistance unit 15 . The upper surface 13 may be coated with an anti-oxidation material film (not shown) to ensure that the resistor 10 is protected from oxidation during manufacture, storage and processing. The anti-oxidation film material can be rosin, active resin, azole and so on. The anti-oxidation film material is located on the upper surface of the resistance unit. The anti-oxidation film material can be applied by spraying, ...

Embodiment 2

[0043] This embodiment is an embodiment of the manufacturing method for manufacturing the resistor in the first embodiment.

[0044] The manufacturing method of the resistor includes the following steps

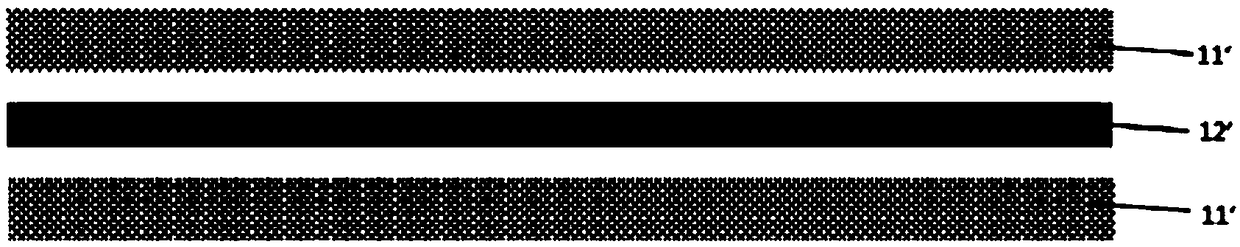

[0045] (1), such as figure 2 As shown, the electrode material and alloy material with a fixed thickness are divided into electrode strips 11' and resistance element strips 12' of preset length and width, and the thickness and width of the strips are determined by the preset resistance value

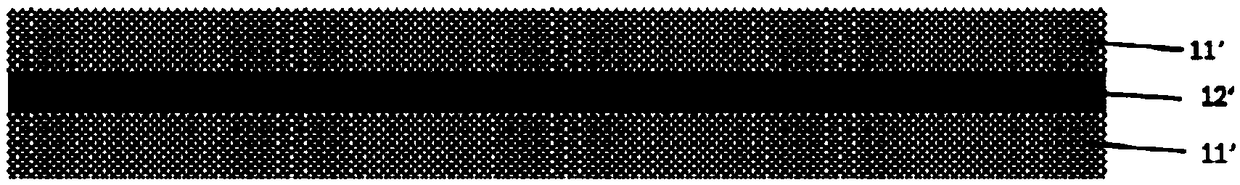

[0046] (2), such as image 3 As shown, two strip-shaped electrode strips 11 ′ are connected to both sides of a strip-shaped resistance element strip 12 ′ to form a three-composite strip.

[0047] (3), such as Figure 4 As shown, several slots are hollowed out on one side of the three-composite strip, and two adjacent slots divide an electrode strip 11` into a single electrode unit, while two adjacent slots The groove divides the resistance element strip body 12 ′ into a single resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com