Coal mine underground strengthening-weakening roof impact mine pressure prevention method

A preventive method and technology of rock burst, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problem that the strength and frequency of rock burst cannot be effectively controlled, the radius of single-hole cracking is limited, and the weakening effect of the roof is not effective. Obvious problems, to achieve a good effect of rock burst prevention, weakening effect and efficiency balance, and improve the effect of weakening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

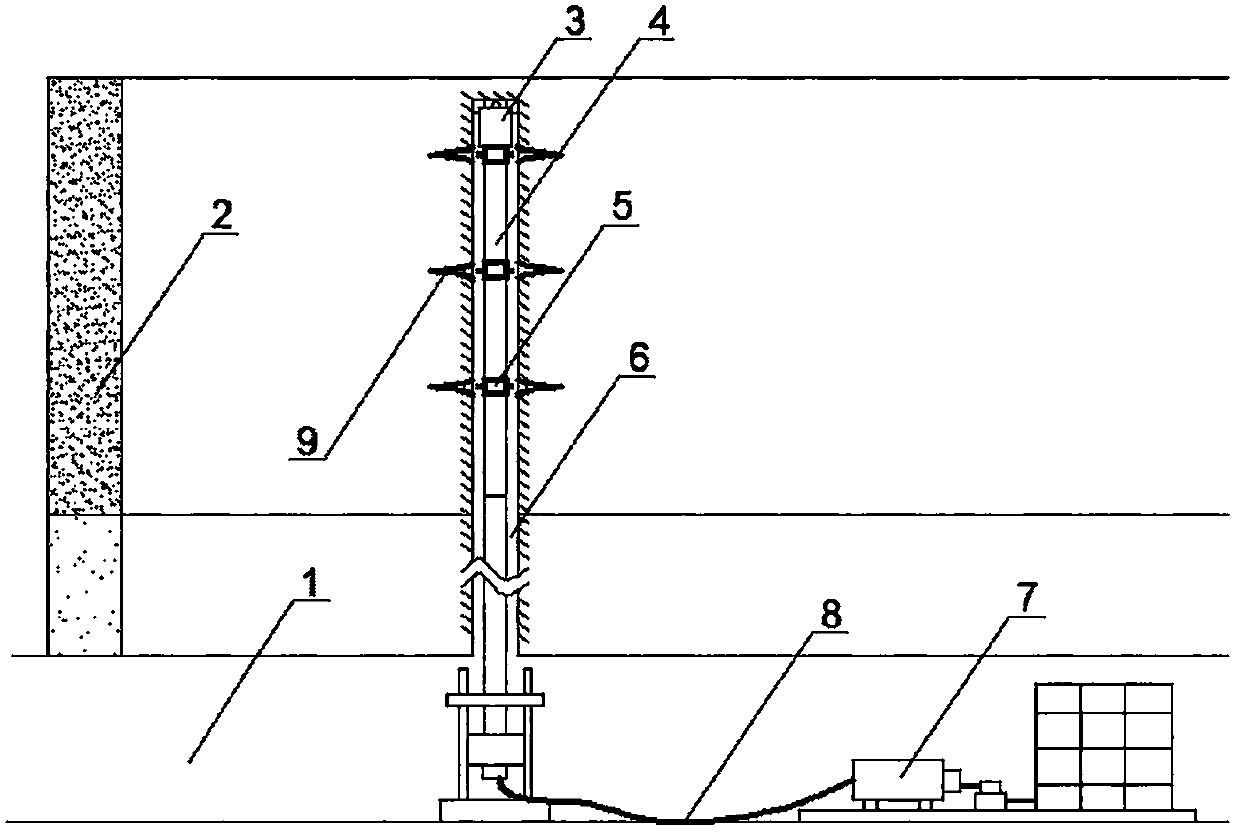

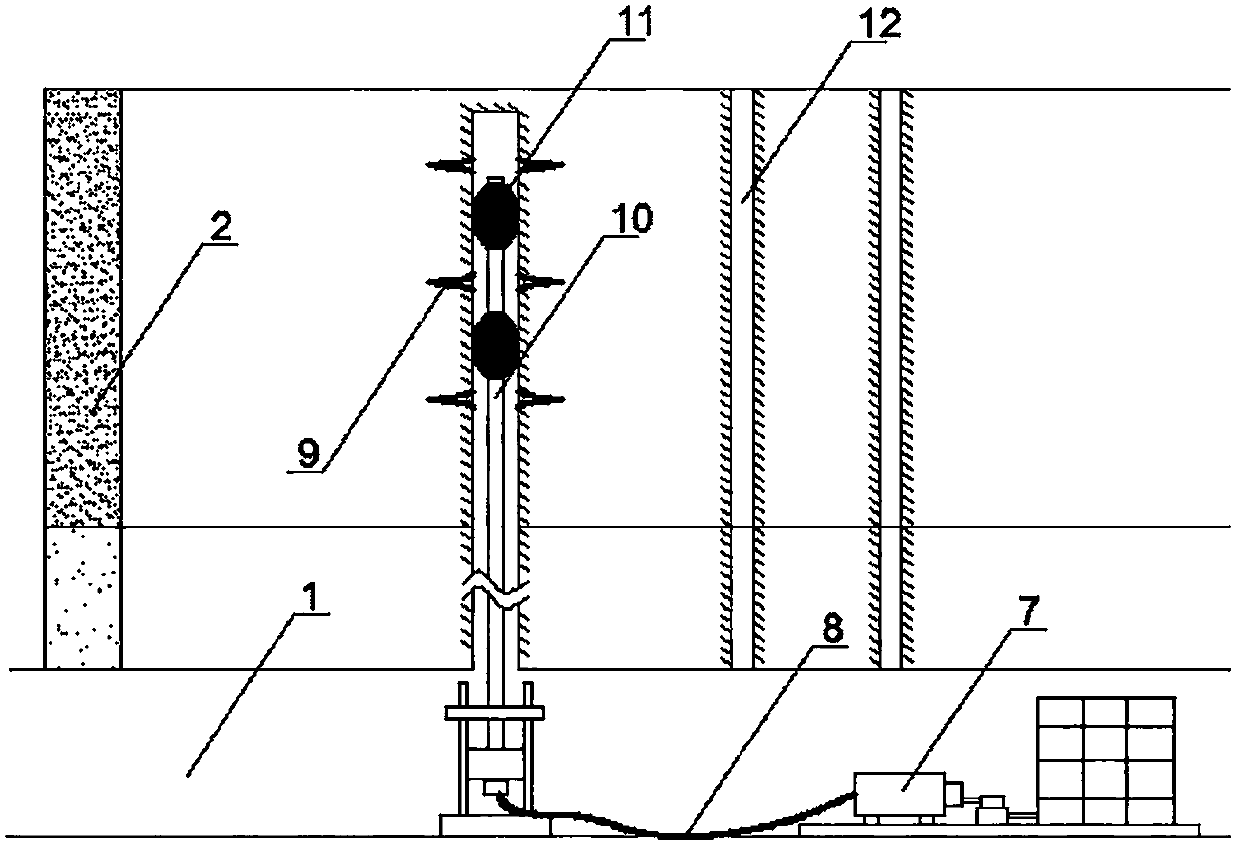

[0030] figure 1 with 2 What is shown is a preferred embodiment of the method for preventing rock burst of a strong and weakened roof under a coal mine according to the present invention.

[0031] The method for preventing impact rock pressure on the strong and weakened roof under the coal mine comprises the following steps:

[0032] (a) In the excavation space 1, according to a certain elevation angle, drill holes to the basic roof 2, the diameter of the drill bit 3 is Ф65mm, the drill pipe 4 is hollow, and the outer diameter is Ф50mm, the overall pressure resistance of the drill bit 3 and the drill pipe 4 Greater than 60MPa, starting from the drill bit 3, an ejector 5 is installed every 1m along the drill pipe 4;

[0033] (b) When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Withstand voltage | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com