Artificial wave making device and method

A wave-making and artificial technology, applied in the field of artificial wave-making devices, can solve the problems of high energy, poor sustainability and long duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

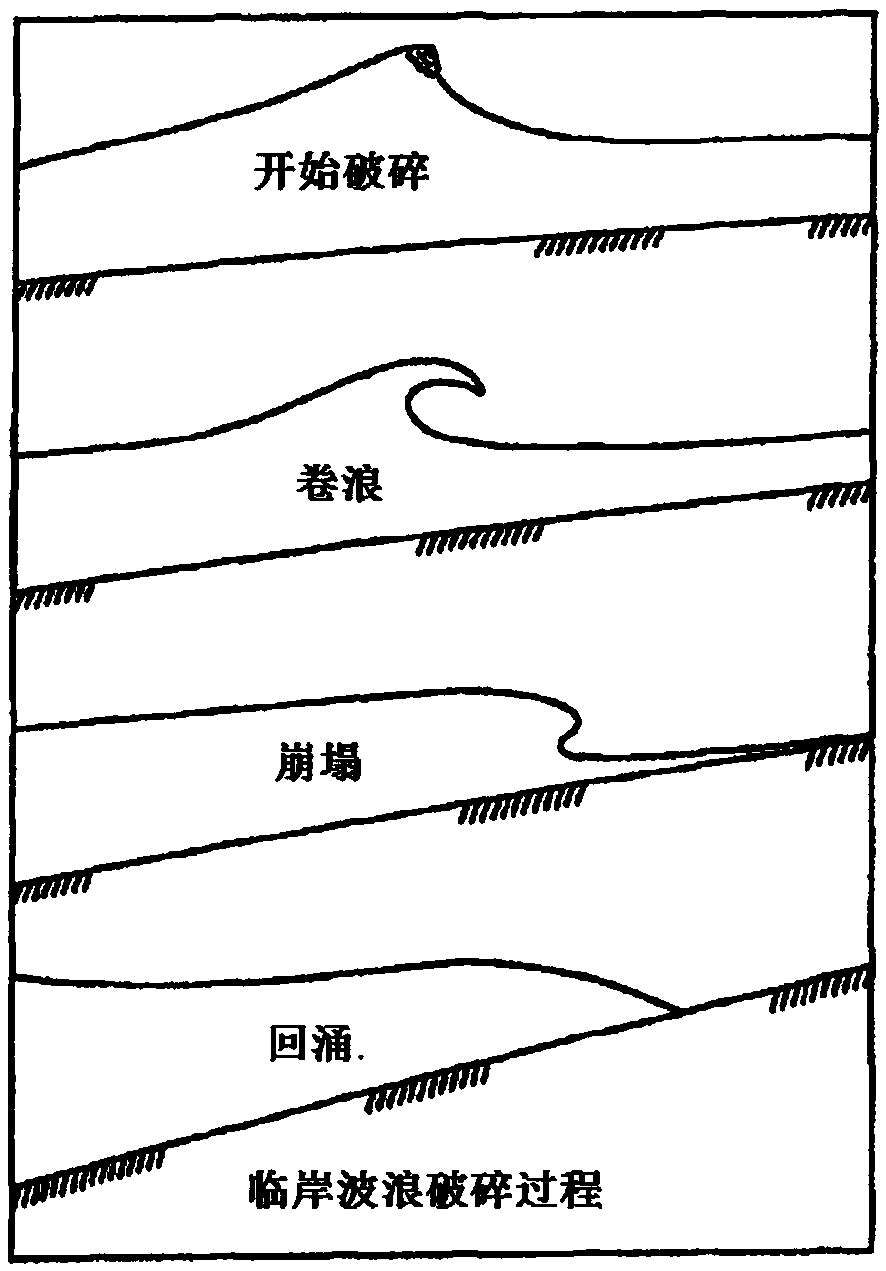

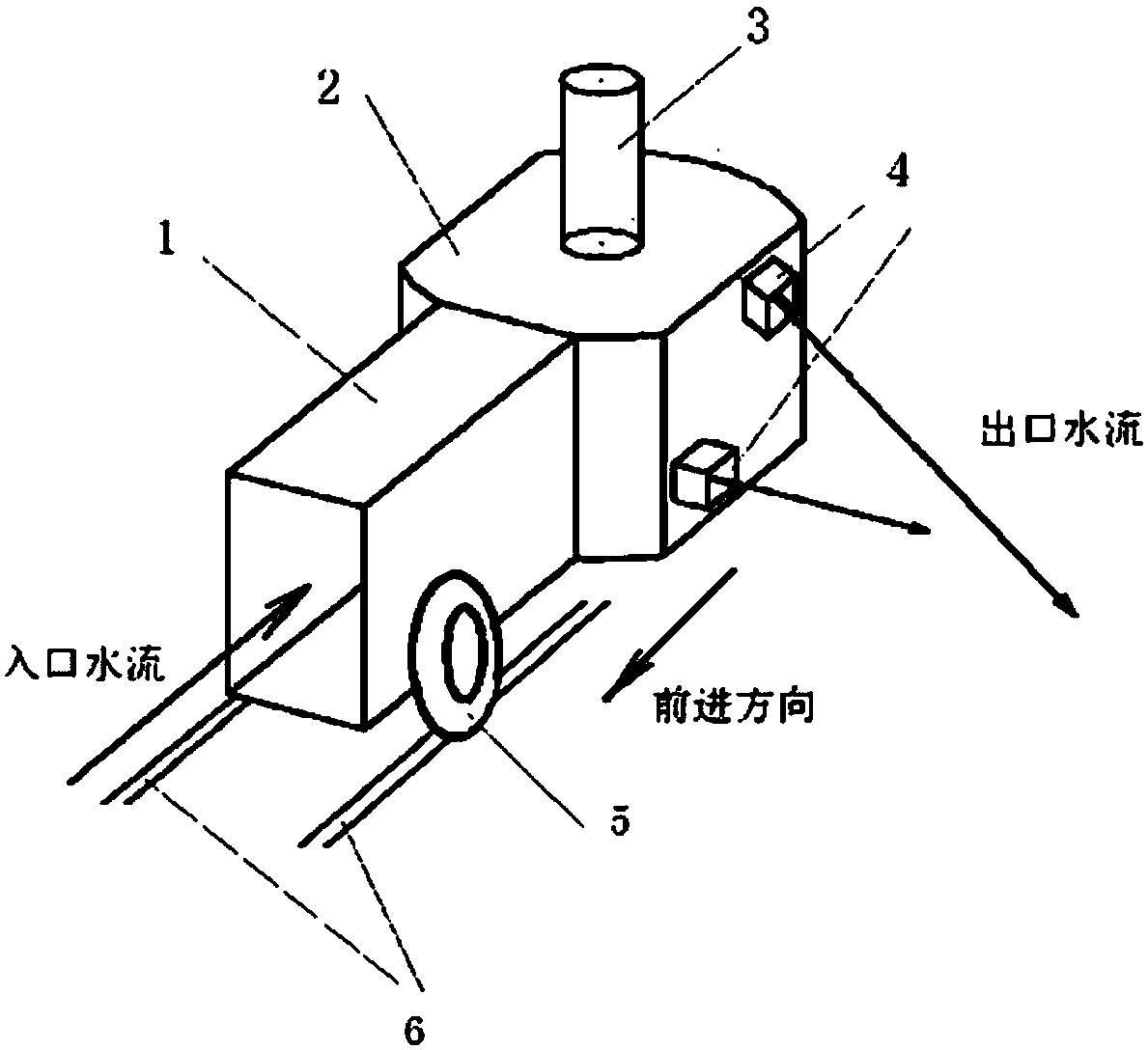

[0027] The present invention is a new type of artificial wave-making device which uses a water pump to drive the water flow and synthesizes various wave shapes vectorially in the pool through multiple jet outlets. The water pump installed on the wave-making device is sucked in from the front of the wave-making device through the water inlet. After the pool water is pressurized, jets are sprayed from one or more jets connected to the side of the wave-making device. According to the requirements of formula (3) and the specific project implementation conditions, multiple jets with different angles and speeds are The vector synthesis near the water surface of the wave pool, the speed and angle of the jet flow are determined by the formula (3), and waves of any wave height and wave shape can be formed, including curling waves, and there is no special requirement for the shape of the pool bottom. The present invention does not require external traction power, the wave-making device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com