Manufacturing method of four-side elastic hollowed-out fabric

A production method and four-way elastic technology, which is applied in the field of fabric processing, can solve problems such as difficulty in improving the quality of the fabric surface, difficulty in tightness of the empty reed, and different hollow sizes, so as to achieve the effect of improving refreshing value, improving product quality, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

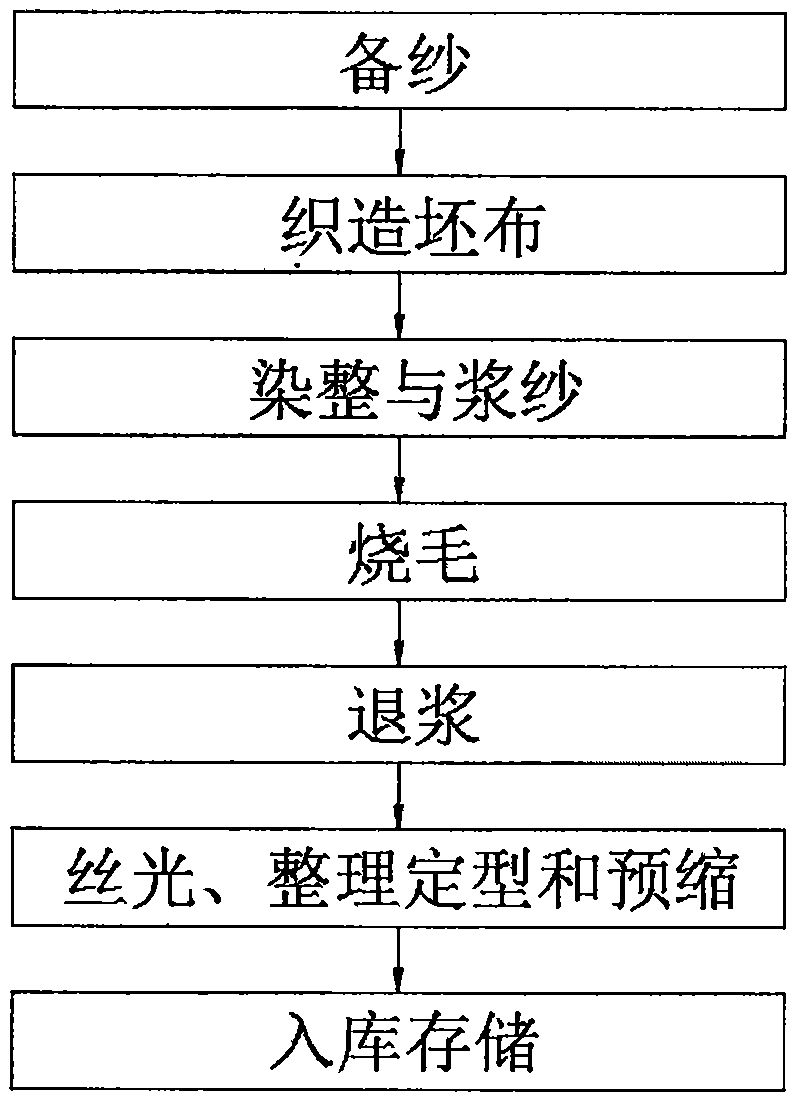

[0023] Example 1: See figure 1 , the present invention provides a kind of manufacturing method of four-sided elastic hollow fabric, comprising the following steps:

[0024] 1) Yarn preparation: Prepare a certain amount of 50D36F Dupont T-400 fiber, 50D72F cationic fiber and 100D alkali-soluble and easily alkali-soluble yarn for use;

[0025] 2) Weaving gray cloth: the yarn produced by combining 50D36F Dupont T-400 fiber and 50D72F cationic fiber with 100D alkali-soluble and easily alkali-soluble yarn is used to weave gray cloth in the same ratio of warp and weft at a ratio of 10:2;

[0026] 3) Dyeing and finishing and sizing: through dyeing and finishing, the easily alkali-soluble yarn in gray silk is quickly dissolved in the strong alkali process, and the T-400 yarn is uniformly shrunk due to high-pressure alkali pressure in the process to form a certain elastic effect. This makes the fabric have a beautiful appearance with four-sided elasticity and uniform hollowing; and si...

Embodiment 2

[0038] Example 2: See figure 1 , the present invention provides a kind of manufacturing method of four-sided elastic hollow fabric, comprising the following steps:

[0039] 1) Yarn preparation: Prepare a certain amount of 50D36F Dupont T-400 fiber, 50D72F cationic fiber and 100D alkali-soluble and easily alkali-soluble yarn for use;

[0040] 2) Weaving gray cloth: the yarn produced by combining 50D36F Dupont T-400 fiber and 50D72F cationic fiber with 100D alkali-soluble and easily alkali-soluble yarn is used to weave gray cloth in the same ratio of warp and weft at a ratio of 10:2;

[0041] 3) Dyeing and finishing and sizing: through dyeing and finishing, the easily alkali-soluble yarn in gray silk is quickly dissolved in the strong alkali process, and the T-400 yarn is uniformly shrunk due to high-pressure alkali pressure in the process to form a certain elastic effect. This makes the fabric have a beautiful appearance with four-sided elasticity and uniform hollowing; and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com